Description

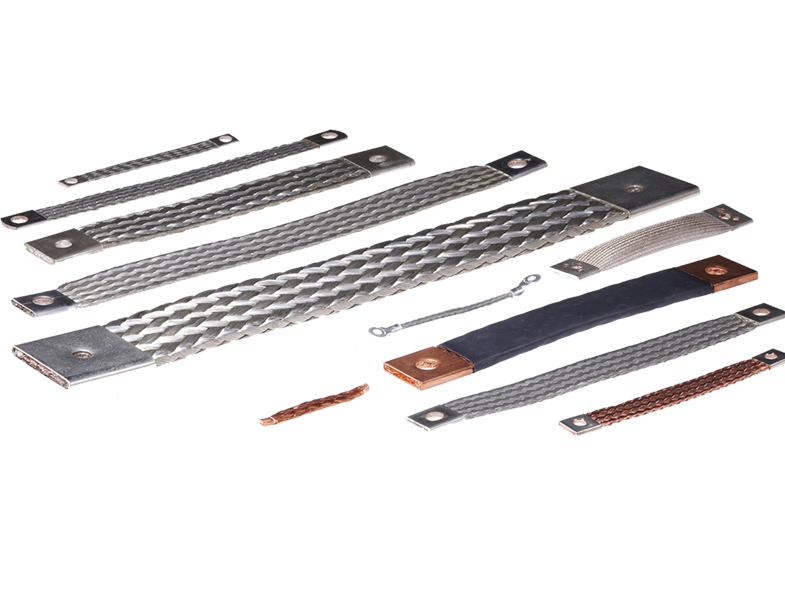

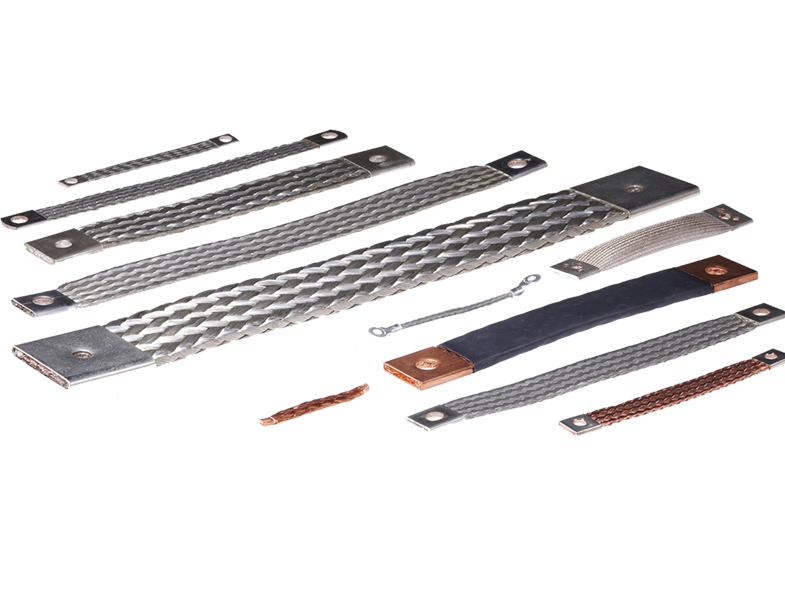

The earthing connection is a braid of copper also named as stranded wire. They are very flexible electrical conductor which can be produced in various sizes. The flexible earth strap can be manufactured in the following materials: bare copper, tinned copper, silver-plated copper, and galvanized copper, aluminum and precious metals.

Product application

Earthing connections and braides are used everywhere in the electrical industry, electrical engineering, automotive engineering, aeronautical engineering, space travel, data technology as flexible conductors, shielding braids, ground connectors, earthing cables or armouring. Technical Dsta

Technical Dsta

Tinned Copper Braids:-

The Construction Of Copper Braid Is Usually Written As:

48 / 30 / 0.15, Where:

48 = The Number Of Carriers

30 =The Number Of Wires Per Carrier

0.15 = The Diameter Of Each Wire In Mm

The Cross Sectional Area (Csa) Of A Copper Braid Can Be Calculated From This Information:

(Carriers X Wires Per Carrier X Wire Diameter ² X 3.142) / 4

So, For A Copper Braid With The Specification: 48 / 30 / 0.15, This Would Be:

48 X 30 X 0.15² X 3.142 / 4 = 101.80 / 4 =25.45 Mm²

Finish In Tinned Copper Braids Available:-

Bare Copper / Plain Copper / Red Copper

- Electro Tin Plated Copper

- Electro Nickel Plated Copper

- 99.99% Pure Silver Electro Plated Copper

- Enamel Coated, Which Insulates Each Wire

- And Other Finishes On Request. Technical Information

Technical Information

The earthing connection is a braid of copper also named as stranded wire. They are very flexible electrical conductor which can be produced in various sizes. The flexible earth strap can be manufactured in the following materials: bare copper, tinned copper, silver-plated copper, and galvanized copper, aluminum and precious metals.

Product application

Earthing connections and braides are used everywhere in the electrical industry, electrical engineering, automotive engineering, aeronautical engineering, space travel, data technology as flexible conductors, shielding braids, ground connectors, earthing cables or armouring.

Tinned Copper Braids:-

The Construction Of Copper Braid Is Usually Written As:

48 / 30 / 0.15, Where:

48 = The Number Of Carriers

30 =The Number Of Wires Per Carrier

0.15 = The Diameter Of Each Wire In Mm

The Cross Sectional Area (Csa) Of A Copper Braid Can Be Calculated From This Information:

(Carriers X Wires Per Carrier X Wire Diameter ² X 3.142) / 4

So, For A Copper Braid With The Specification: 48 / 30 / 0.15, This Would Be:

48 X 30 X 0.15² X 3.142 / 4 = 101.80 / 4 =25.45 Mm²

Finish In Tinned Copper Braids Available:-

Bare Copper / Plain Copper / Red Copper

- Electro Tin Plated Copper

- Electro Nickel Plated Copper

- 99.99% Pure Silver Electro Plated Copper

- Enamel Coated, Which Insulates Each Wire

- And Other Finishes On Request.

| DIMENSIONS (mm) | HOLE DIAMETER (A) (mm) | LENGTH (B) (mm) | CSA (mm) | WEIGHT (kg) |

| 12 x 1 | 7 | 200 | 6 | 0.01 |

| 12 x 1 | 7 | 400 | 6 | 0.02 |

| 15 x 1.5 | 7 | 200 | 10 | 0.02 |

| 15 x 1.5 | 7 | 400 | 10 | 0.04 |

| 19 x 2.5 | 9 | 200 | 16 | 0.03 |

| 19 x 2.5 | 9 | 400 | 16 | 0.06 |

| 25 x 3 | 11 | 200 | 25 | 0.05 |

| 25 x 3 | 11 | 400 | 25 | 0.1 |

| 25 x 3.5 | 11 | 200 | 35 | 0.09 |

| 25 x 3.5 | 11 | 400 | 35 | 0.15 |

| 30 x 5 | 11 | 200 | 50 | 0.1 |

| 30 x 5 | 11 | 400 | 50 | 0.2 |

| 32 x 6 | 13 | 200 | 70 | 0.13 |

| 32 x 6 | 13 | 400 | 70 | 0.25 |

| 37 x 6 | 13 | 200 | 95 | 0.19 |

| 37 x 6 | 13 | 400 | 95 | 0.37 |

| 45 x 6 | 17 | 200 | 120 | 0.23 |

| 45 x 6 | 17 | 400 | 120 | 0.46 |

| 50 x 8 | 17 | 200 | 150 | 0.3 |

| 50 x 8 | 17 | 400 | 150 | 0.6 |