Overview

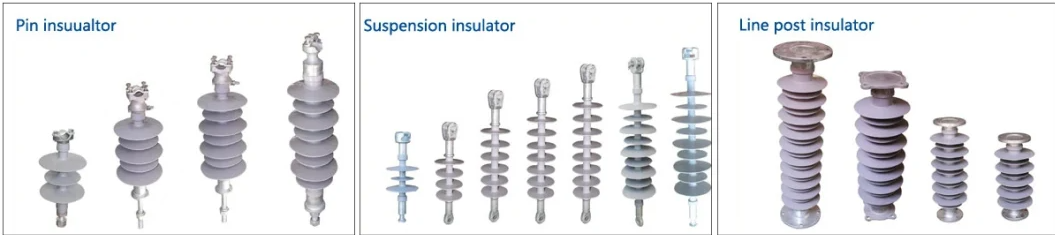

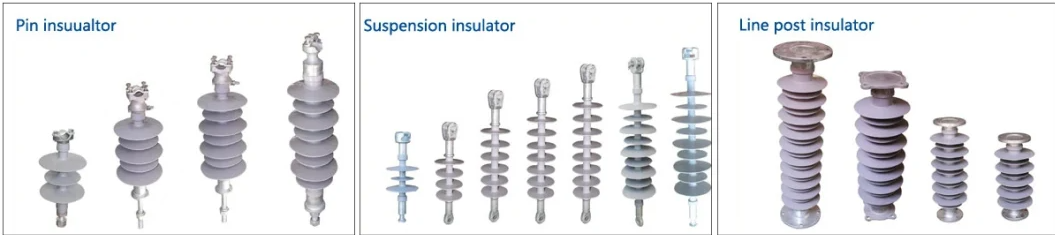

The silicone rubber shed adopt the whole packing pressure technique, and then to solve the key problem – interface electric spark puncture, which would affect the reliability of composite insulator.

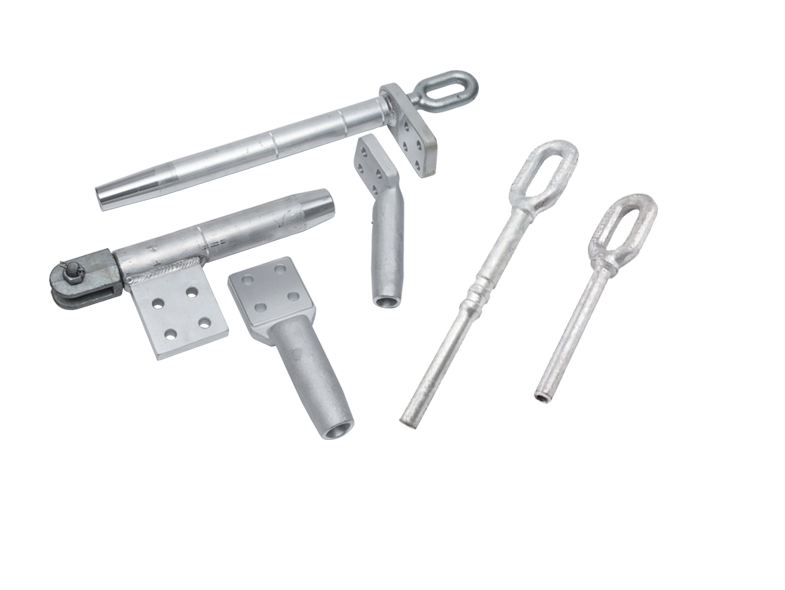

The connection of the glass fiber rod and metal fittings adopts the pressure welding technique of the international advanced level and have the full automatic sound wave detection of defects system, high intension, beautiful outline, small volume, light weight, and the metal fitting of galvanization can corrosion prevention and exchange used with porcelain insulator.

The polymer composite pin insulator is reliable structure, can’t damage the core rod, and take full advantage of the mechanical strength.

Parameter

The silicone rubber shed adopt the whole packing pressure technique, and then to solve the key problem – interface electric spark puncture, which would affect the reliability of composite insulator.

The connection of the glass fiber rod and metal fittings adopts the pressure welding technique of the international advanced level and have the full automatic sound wave detection of defects system, high intension, beautiful outline, small volume, light weight, and the metal fitting of galvanization can corrosion prevention and exchange used with porcelain insulator.

The polymer composite pin insulator is reliable structure, can’t damage the core rod, and take full advantage of the mechanical strength.

Parameter

| Item No. | Dimensions | Mechanical | Electrical | ||||||||

| Height | Min Dry Arcing Distance (mm) | Min Creepage Distance (mm) | Diameter of the rod (mm) | Number of sheds | Max Design Cantilever Load (MDCL) (kN) | Specified Cantilever Load (SCL) (kN) | Rated Voltage kV | Highest Voltage kV | Lightning Impulse Withstand BIL kV | Power Frequency Flashover Voltage (Dry/Wet) kV | |

| (mm) | |||||||||||

| FPQ-11/4 | 235 | 200 | 345 | 24 | 2 | 4 | 2 | 11 | 12 | 95 | 38 |

| FPQ-18/5 | 245 | 210 | 450 | 24 | 3 | 5 | 2.5 | 18 | 15 | 95 | 45/40 |

| FPQ-27/3 | 340 | 290 | 660 | 24 | 5 | 3 | 1.5 | 24 | 27 | 160 | 60 |

| FPQ-33/12.5 | 430 | 370 | 1040 | 38 | 5 | 12.5 | 6.25 | 33 | 36 | 230 | 95 |