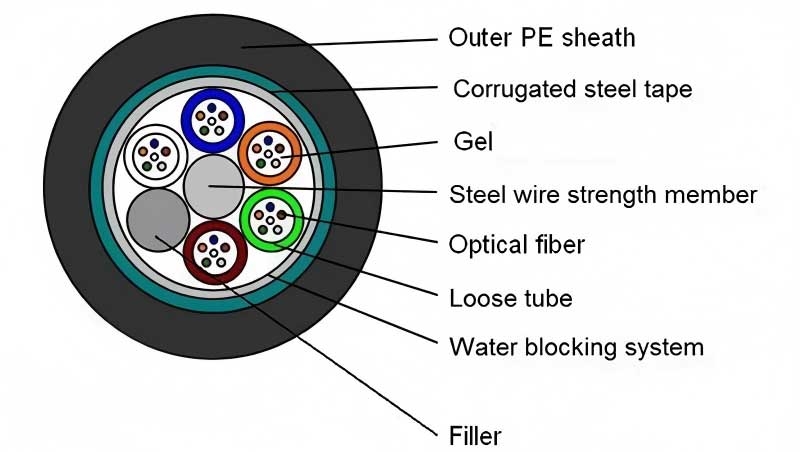

Product Structure Diagram

Product Description

The fibers are positioned in a loose tube made of high modulus plastic and filled with gel. Tubes(and fillers) are stranded around the metallic strength member to form the cable core. The steel tape(CST) is longitudinally armored over the cable core, which is filled with water blocking compound. Finally a PE jacket is extruded.

Product features

Good mechanical and thermal performance

Steel wire as the central strength member

Hydrolysis resistant loose tube

Tube filling compound ensures critical protection of fiber

Specially designed stranded structure eliminating contraction of tubes

Rugged, durable PE jacket protects against UV radiation, fungus etc.

Crush resistance and flexibility

Water-blocking measures:

- Loose tube gel-filled

- 100% cable filling compound

- Corrugated steel tape(CST) enhancing moisture-proof

Application

Duct / Non Self-supporting Aerial Installation.

Technical Specifications

Product Parameters

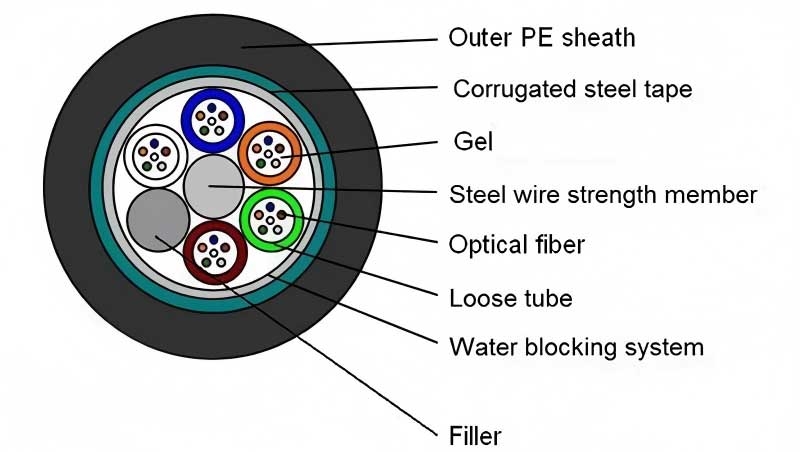

Product Description

The fibers are positioned in a loose tube made of high modulus plastic and filled with gel. Tubes(and fillers) are stranded around the metallic strength member to form the cable core. The steel tape(CST) is longitudinally armored over the cable core, which is filled with water blocking compound. Finally a PE jacket is extruded.

Product features

Good mechanical and thermal performance

Steel wire as the central strength member

Hydrolysis resistant loose tube

Tube filling compound ensures critical protection of fiber

Specially designed stranded structure eliminating contraction of tubes

Rugged, durable PE jacket protects against UV radiation, fungus etc.

Crush resistance and flexibility

Water-blocking measures:

- Loose tube gel-filled

- 100% cable filling compound

- Corrugated steel tape(CST) enhancing moisture-proof

Application

Duct / Non Self-supporting Aerial Installation.

Technical Specifications

Product Parameters

| Project | Technical indicators | ||||||||

| Counts | 2-30 | 32-36 | 38-60 | 62-72 | 74-96 | 98-120 | 122-144 | 146-216 | 218-288 |

| Max.fiber counts per tube | 6 | 6 | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Units(Tubes or Fillers) | 5 | 6 | 5 | 6 | 8 | 10 | 12 | 18 | 24 |

| Cable Diameter(mm) | 9.2 | 9.6 | 9.7 | 10.2 | 11.5 | 12.8 | 14 | 14.3 | 16.2 |

| Reference weight(Kg/km) | 87 | 102 | 98 | 118 | 143 | 170 | 197 | 204 | 255 |

| Fiber Type | G652D G655 G657 50/125 62.5/125 | ||||||||

| Tensile Strength(N) | Long/Short Term:600/1500 | ||||||||

| Crush Resistance(N/100mm) | Long/Short Term:300/1000 | ||||||||

| Bending Radius(mm) | Static/Dynamic:10D/20D | ||||||||

| Temperature(℃) | Storage /Operation:-40℃~+70℃ | ||||||||