AAAC – The full name: All Aluminum Alloy Conductor. It is used for primary and secondary overhead transmission and distribution services. This has been designed utilizing a high-strength aluminum alloy to achieve a high strength-to-weight ratio and better sag characteristic. The conductor has a higher resistance to corrosion than ACSR.

CONDUCTORS:

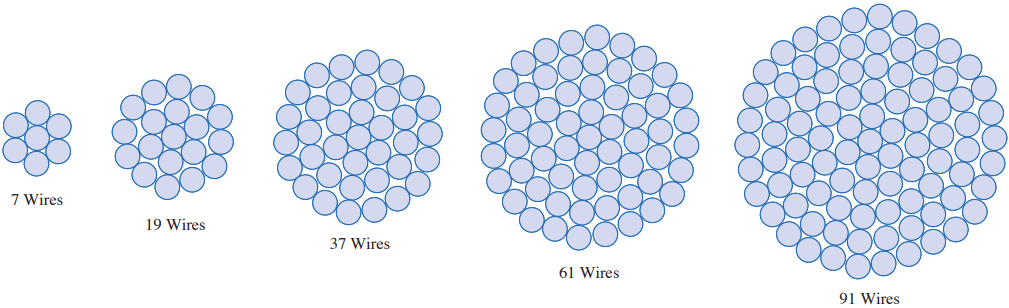

Stranded 6201-T81 high strength aluminum conductors, conforming to ASTM specifications B399 are concentriclay-stranded, similar in construction and appearance to 1350 aluminum alloy grade aluminum conductors, and has a greater resistance to abrasion than conductors of 1350 aluminum alloy.

AAAC cable consists of aluminum alloy wires and the wires are concentrically stranded.

This section deals with aluminum alloys of the magnesium-silicon type heat treatable according to the applicable International Standard, whose electrical and mechanical properties are all within the values suggested by the relevant standard.

Conductors with all other recognized specifications can also be supplied. The mentioned alloys have higher strength but lower conductivity than pure aluminum.

Being lighter, alloy conductors can sometimes be used to advantage in place of more conventional ACSR; by having lower breaking loads than the later ones, its use becomes particularly favorable when the ice and wind loads are low.

STANDARD

1. American Standard-ASTM B 399/B 399M

2. German Standards-DIN 48201-6

3. British Standards-BS EN 50182 BS 3242

4. International Electrotechnical Commission International Standards&China National Standards-IEC 61089 GB/T 1179

5. Russian National Standard-AAAC GOST 839-80

6. French Sizes NFC 34

ASTM B 399/B 399M Full Size

|

Code Name |

Area | Size&Stranding ACSR with equal diameter | No. And diameter of wires | Cable diameter | Weight | Rated Strength | Strand Length | ||

| Nominal | Actual | ||||||||

| MCM | mm² | AWG or MCM | AI/Steel | mm | mm | Kg/km | kN | m±5% | |

| Akron | 30.58 | 15.48 | 6 | 6/1 | 7/1.68 | 5.04 | 42.7 | 4.92 | 3000 |

| Alton | 48.69 | 24.71 | 4 | 6/1 | 7/2.12 | 6.35 | 68.0 | 7.84 | 3000 |

| Ames | 77.47 | 39.22 | 2 | 6/1 | 7/2.67 | 8.02 | 108 | 12.45 | 2000 |

| Azusa | 123.3 | 62.38 | 1/0 | 6/1 | 7/3.37 | 10.11 | 172 | 18.97 | 2000 |

| Ananeim | 155.4 | 78.65 | 2/0 | 6/1 | 7/3.78 | 11.35 | 217 | 23.93 | 3000 |

| Amherst | 195.7 | 99.22 | 3/0 | 6/1 | 7/4.25 | 12.75 | 273 | 30.18 | 2500 |

| Alliance | 246.9 | 125.1 | 4/0 | 6/1 | 7/4.77 | 14.31 | 345 | 38.05 | 2000 |

| Butte | 312.8 | 158.6 | 266.8 | 26/7 | 19/3.26 | 16.30 | 437 | 48.76 | 3000 |

| Canton | 394.5 | 199.9 | 336.4 | 26/7 | 19/3.66 | 18.30 | 551 | 58.91 | 2500 |

| Cairo | 465.5 | 235.8 | 397.5 | 26/7 | 19/3.98 | 19.88 | 650 | 69.48 | 2000 |

| Darien | 559.5 | 283.5 | 477 | 26/7 | 19/4.36 | 21.79 | 781 | 83.52 | 2000 |

| Elgin | 652.4 | 330.6 | 556.5 | 26/7 | 19/4.71 | 23.54 | 911 | 97.42 | 1500 |

| Flint | 740.8 | 375.3 | 636 | 26/7 | 37/3.59 | 25.16 | 1035 | 108.21 | 3000 |

| Greely | 927.2 | 469.8 | 795 | 26/7 | 37/4.02 | 28.14 | 1295 | 135.47 | 2500 |

AAAC 6201 ASTM B 399

|

Conductor size |

Sectional Area |

Stranding |

Diameter of Complete Conductor |

Weight |

Rated Strength |

DC Resistance @ 20°C |

Current Capacity |

||

|

No. of Aluminium Wires |

Individual wire diameter |

@ 75°C |

@ 85°C |

||||||

|

(kcmil) |

(mm²) |

(No.) |

(mm) |

(mm) |

(Kg/Km) |

KN |

(Ω/Km) |

(Ampere) |

(Ampere) |

|

1439.2 |

729 |

61 |

3.9 |

35.1 |

1999 |

207 |

0.04597 |

693 |

897 |

|

1348.8 |

685 |

61 |

3.78 |

34.02 |

1878 |

194 |

0.04893 |

671 |

865 |

|

1259.6 |

638 |

61 |

3.65 |

32.85 |

1751 |

181 |

0.05248 |

646 |

831 |

|

1165.1 |

590 |

61 |

3.51 |

31.59 |

1620 |

167 |

0.05675 |

620 |

794 |

|

1077.4 |

547 |

61 |

3.38 |

30.42 |

1502 |

156 |

0.0612 |

595 |

760 |

|

927.2 |

470 |

37 |

4.02 |

28.14 |

1289 |

135 |

0.07133 |

547 |

694 |

|

740.8 |

375 |

37 |

3.59 |

25.13 |

1028 |

107 |

0.08944 |

482 |

607 |

|

652.4 |

331 |

19 |

4.71 |

23.55 |

908.3 |

97 |

0.1012 |

449 |

564 |

|

559.5 |

284 |

19 |

4.36 |

21.8 |

778.3 |

83.1 |

0.1181 |

412 |

514 |

|

465.4 |

236 |

19 |

3.98 |

19.9 |

648.6 |

69.2 |

0.1417 |

371 |

461 |

|

394.5 |

200 |

19 |

3.66 |

18.3 |

548.5 |

58.6 |

0.1676 |

337 |

417 |

|

312.8 |

159 |

19 |

3.26 |

16.3 |

435.1 |

46.5 |

0.2112 |

295 |

362 |

|

246.9 |

125 |

7 |

4.77 |

14.31 |

343.2 |

37.8 |

0.2678 |

256 |

313 |

|

195.7 |

99.3 |

7 |

4.25 |

12.75 |

272.5 |

30 |

0.3373 |

224 |

272 |

|

155.4 |

78.6 |

7 |

3.78 |

11.34 |

215.6 |

23.8 |

0.4264 |

195 |

236 |

|

123.3 |

62.4 |

7 |

3.37 |

10.11 |

171.3 |

18.9 |

0.5365 |

170 |

205 |

|

77.47 |

39.2 |

7 |

2.67 |

8.01 |

107.5 |

12.4 |

0.8547 |

129 |

154 |

|

48.69 |

24.7 |

7 |

2.12 |

6.36 |

67.8 |

7.83 |

1.356 |

98 |

116 |

|

30.58 |

15.5 |

7 |

1.68 |

5.04 |

42.58 |

4.92 |

2.159 |

74 |

88 |

|

1750 |

886 |

61 |

4.3 |

38.7 |

2431 |

251 |

0.03781 |

767 |

1002 |

|

1500 |

759 |

61 |

3.98 |

35.82 |

2082 |

215 |

0.04414 |

708 |

918 |

|

1250 |

631 |

61 |

3.63 |

32.67 |

1732 |

179 |

0.05306 |

642 |

826 |

|

1000 |

508 |

37 |

4.18 |

29.26 |

1393 |

146 |

0.06597 |

571 |

727 |

|

900 |

456 |

37 |

3.96 |

27.72 |

1250 |

131 |

0.07351 |

538 |

682 |

|

800 |

404 |

37 |

3.73 |

26.11 |

1109 |

116 |

0.08285 |

503 |

636 |

|

750 |

381 |

37 |

3.62 |

25.34 |

1045 |

109 |

0.08796 |

487 |

613 |

|

700 |

354 |

37 |

3.49 |

24.43 |

971.2 |

101 |

0.09464 |

467 |

587 |

|

650 |

330 |

37 |

3.37 |

23.59 |

905.5 |

94.9 |

0.1015 |

449 |

563 |

|

600 |

303 |

37 |

3.23 |

22.61 |

831.9 |

91 |

0.11049 |

428 |

535 |

|

550 |

279 |

37 |

3.1 |

21.7 |

766.2 |

83.9 |

0.11995 |

408 |

510 |

|

500 |

253 |

19 |

4.12 |

20.6 |

695 |

74.2 |

0.13224 |

386 |

480 |

|

450 |

228 |

19 |

3.91 |

19.55 |

626 |

66.8 |

0.14683 |

364 |

451 |

|

400 |

203 |

19 |

3.69 |

18.45 |

557.5 |

59.5 |

0.16486 |

340 |

421 |

|

350 |

178 |

19 |

3.45 |

17.25 |

487.3 |

52 |

0.1886 |

315 |

388 |

|

300 |

152 |

19 |

3.19 |

15.95 |

416.7 |

46.6 |

0.22059 |

287 |

353 |

|

250 |

126 |

19 |

2.91 |

14.55 |

346.7 |

38.8 |

0.26509 |

258 |

316 |

|

211.6 |

107 |

7 |

4.42 |

13.26 |

294.7 |

32.5 |

0.31188 |

234 |

285 |

|

167.8 |

84.9 |

7 |

3.93 |

11.79 |

233 |

25.7 |

0.3945 |

204 |

247 |

|

133.1 |

67.3 |

7 |

3.5 |

10.5 |

184.8 |

20.4 |

0.49738 |

178 |

215 |

|

105.6 |

53.5 |

7 |

3.12 |

9.36 |

146.8 |

17 |

0.62592 |

155 |

187 |

|

66.36 |

33.5 |

7 |

2.47 |

7.41 |

92 |

10.6 |

0.9987 |

118 |

140 |

|

41.74 |

21.1 |

7 |

1.96 |

5.88 |

57.9 |

6.69 |

1.586 |

89 |

106 |

|

26.24 |

13.2 |

7 |

1.55 |

4.65 |

36.2 |

4.18 |

2.5361 |

67 |

79 |

DIN 48201-6

| Nominal Area | Stranding | Overall Diameter | Weight | Rated Strength | Electrical Resistance | Current Rating* | |

| Nominal | Teorical | ||||||

| mm^2 | mm^2 | No.×mm | mm | kg/km | KN | Ω/Km | A |

| 16 | 15.89 | 7/1.70 | 5.1 | 43 | 4.44 | 2.0742 | 78 |

| 25 | 24.25 | 7/2.10 | 6.3 | 66 | 6.77 | 1.3593 | 102 |

| 35 | 34.36 | 7/2.50 | 7.5 | 94 | 9.6 | 0.9591 | 126 |

| 50 | 49.48 | 7/3.00 | 9 | 135 | 13.82 | 0.666 | 158 |

| 50 | 48.35 | 19/1.80 | 9 | 133 | 13.5 | 0.6849 | 156 |

| 70 | 65.81 | 19/2.10 | 10.5 | 181 | 18.38 | 0.5032 | 189 |

| 95 | 93.27 | 19/2.50 | 12.5 | 256 | 26.05 | 0.3551 | 234 |

| 120 | 116.99 | 19/2.80 | 14 | 322 | 32.68 | 0.2831 | 269 |

| 150 | 147.11 | 37/2.25 | 15.8 | 406 | 41.09 | 0.2256 | 309 |

| 185 | 181.62 | 37/2.50 | 17.5 | 500 | 50.73 | 0.1828 | 352 |

| 240 | 242.54 | 61/2.25 | 20.3 | 670 | 67.74 | 0.1371 | 420 |

| 300 | 299.43 | 61/2.50 | 22.5 | 827 | 83.63 | 0.111 | 477 |

| 400 | 400.14 | 61/2.89 | 26 | 1104 | 111.76 | 0.0831 | 568 |

| 500 | 499.83 | 61/3.23 | 29.1 | 1379 | 139.6 | 0.0665 | 649 |

| 625 | 626.2 | 91/2.96 | 32.6 | 1732 | 174.9 | 0.0531 | 742 |

| 800 | 802.09 | 91/3.35 | 36.9 | 2218 | 224.02 | 0.0415 | 857 |

| 1000 | 999.71 | 91/3.74 | 41.1 | 2767 | 279.22 | 0.0333 | 971 |

BS EN 50182 BS 3242

| Code | Stranding | Nominal Area | Sectional Area | Overall Diameter | Weight | Rated Strength | Electrical Resistance | Current Rating* |

| No.×mm | mm^2 | mm^2 | mm | kg/km | KN | Ω/Km | A | |

| Box | 7/1.85 | 15 | 18.8 | 5.55 | 51.4 | 5.55 | 1.748 | 87 |

| Acacia | 7/2.08 | 20 | 23.8 | 6.24 | 64.9 | 7.02 | 1.3828 | 101 |

| Almond | 7/2.34 | 25 | 30.1 | 7.02 | 82.2 | 8.88 | 1.0926 | 116 |

| Cedar | 7/2.54 | 30 | 35.5 | 7.62 | 96.8 | 10.46 | 0.9273 | 129 |

| Deodar | 7/2.77 | 35 | 42.2 | 8.31 | 115.2 | 12.44 | 0.7797 | 143 |

| Fir | 7/2.95 | 40 | 47.8 | 8.85 | 130.6 | 14.11 | 0.6875 | 155 |

| Hazel | 7/3.30 | 50 | 59.9 | 9.9 | 163.4 | 17.66 | 0.5494 | 178 |

| Pine | 7/3.61 | 60 | 71.6 | 10.83 | 195.6 | 21.14 | 0.4591 | 199 |

| Holly | 7/3.91 | 70 | 84.1 | 11.73 | 229.5 | 24.79 | 0.3913 | 219 |

| Willow | 7/4.04 | 75 | 89.7 | 12.12 | 245 | 26.47 | 0.3665 | 228 |

| – | 7/4.19 | 80 | 96.52 | 12.57 | 264 | 27.17 | 0.3411 | 245 |

| – | 7/4.44 | 90 | 108.0 | 13.32 | 298 | 30.65 | 0.3023 | 260 |

| Oak | 7/4.65 | 80 | 118.9 | 13.95 | 324.5 | 35.07 | 0.2767 | 272 |

| – | 19/2.82 | 100 | 118.70 | 14.1 | 326 | 33.42 | 0.2787 | 290 |

| Mulberry | 19/3.18 | 125 | 150.9 | 15.9 | 414.3 | 44.52 | 0.2192 | 314 |

| Ash | 19/3.48 | 150 | 180.7 | 17.4 | 496.1 | 53.31 | 0.183 | 351 |

| Elm | 19/3.76 | 175 | 211 | 18.8 | 579.2 | 62.24 | 0.1568 | 386 |

| Poplar | 37/2.87 | 200 | 239.4 | 20.09 | 659.4 | 70.61 | 0.1387 | 416 |

| – | 37/3.05 | 225 | 270.30 | 21.35 | 744 | 76.08 | 0.1227 | 448 |

| Sycamore | 37/3.23 | 250 | 303.2 | 22.61 | 835.2 | 89.4 | 0.1095 | 480 |

| Upas | 37/3.53 | 300 | 362.1 | 24.71 | 997.5 | 106.82 | 0.0917 | 535 |

| Walnut | 37/3.81 | 350 | 421.80 | 26.67 | 1162 | 118.72 | 0.07860 | 584 |

| Yew | 37/4.06 | 400 | 479 | 28.42 | 1319.6 | 141.31 | 0.0693 | 633 |

| Totara | 37/4.14 | 425 | 498.1 | 28.98 | 1372.1 | 146.93 | 0.0666 | 648 |

| Rubus | 61/3.50 | 500 | 586.9 | 31.5 | 1622 | 173.13 | 0.0567 | 714 |

| Sorbus | 61/3.71 | 600 | 659.4 | 33.39 | 1822.5 | 194.53 | 0.0505 | 764 |

| Araucaria | 61/4.14 | 700 | 821.1 | 37.26 | 2269.4 | 242.24 | 0.0406 | 868 |

| Redwood | 61/4.56 | 800 | 996.2 | 41.04 | 2753.2 | 293.88 | 0.0334 | 970 |

IEC 61089 GB/T 1179

| Code | A2/A3 Sectional Area | A2/A3 Stranding | A2/A3 Overall Diameter | A2/A3 Weight | A2/A3 Rated Strength | Electrical Resistance | Current Rating* |

| mm^2 | No.×mm | mm | kg/km | KN | Ω/Km | A | |

| 16 | 18.4/18.6 | 7/1.83/1.84 | 5.49/5.52 | 50.4/50.8 | 5.43/6.04 | 1.7896 | 86 |

| 25 | 28.8/29.0 | 7/2.29/2.30 | 6.87/6.90 | 78.7/79.5 | 8.49/9.44 | 1.1453 | 113 |

| 40 | 46/46.5 | 7/2.89/2.91 | 8.67/8.72 | 125.9/127.1 | 13.58/15.10 | 0.7158 | 151 |

| 63 | 72.5/73.2 | 7/3.63/3.65 | 10.89/10.90 | 198.3/200.2 | 21.39/23.06 | 0.4545 | 200 |

| 100 | 115/116 | 19/2.78/2.79 | 13.9/14.0 | 316.3/319.3 | 33.95/37.76 | 0.2877 | 266 |

| 125 | 144/145 | 19/3.10/3.12 | 15.5/15.6 | 395.4/399.2 | 42.44/47.20 | 0.2302 | 305 |

| 160 | 184/186 | 19/3.51/3.53 | 17.55/17.60 | 506.1/511.0 | 54.32/58.56 | 0.1798 | 355 |

| 200 | 230/232 | 19/3.93/3.95 | 19.65/19.70 | 632.7/638.7 | 67.91/73.20 | 0.1439 | 407 |

| 250 | 288/290 | 19/4.39/4.41 | 21.95/22.1 | 790.8/798.4 | 84.88/91.50 | 0.1151 | 466 |

| 315 | 363/366 | 37/3.53/3.55 | 24.71/24.80 | 998.9/1008.4 | 106.95/115.3 | 0.0916 | 535 |

| 400 | 460/465 | 37/3.98/4.00 | 27.86/28.00 | 1268.4/1280.5 | 135.81/146.40 | 0.0721 | 618 |

| 450 | 518/523 | 37/4.22/4.24 | 29.54/29.70 | 1426.9/1440.5 | 152.79/164.70 | 0.0641 | 663 |

| 500 | 575/581 | 37/4.45/4.47 | 31.15/31.30 | 1585.5/1600.6 | 169.76/183.00 | 0.0577 | 706 |

| 560 | 645/651 | 61/3.67/3.69 | 33.03/33.20 | 1778.4/1795.3 | 190.14/204.96 | 0.0516 | 755 |

| 630 | 725/732 | 61/3.89/3.91 | 35.01/35.20 | 2000.7/2019.8 | 213.9/230.58 | 0.0458 | 809 |

| 710 | 817/825 | 61/4.13/4.15 | 37.17/37.3 | 2254.8/2276.2 | 241.07/259.86 | 0.0407 | 866 |

| 800 | 921/930 | 61/4.38/4.40 | 39.42/39.6 | 2540.6/2564.8 | 271.62/292.80 | 0.0361 | 928 |

| 900 | 1036/1046 | 91/3.81/3.83 | 41.91/42.10 | 2861.1/2888.3 | 305.58/329.40 | 0.0321 | 992 |

| 1000 | 1151/1162 | 91/4.01/4.03 | 44.11/44.40 | 3179/3209 | 339.53/366 | 0.0289 | 1051 |

| 1120 | 1289/1301 | 91/4.25/4.27 | 46.75/46.9 | 3560.5/3594.4 | 380.27/409.92 | 0.0258 | 1118 |

| 1250 | 1439 | 91/4.49 | 49.39 | 3973.7 | 424.41 | 0.0231 | 1185 |

Type Ah GOST 839-80

| Nominal Cross Section | Calculated Cross Section | Number of ires | Conductor Diameter | DC Resistance at 20 | Min. Breaking Load | Conductor Weight |

| mm2 | mm2 | mm | Ω | N | kg/km | |

| 16 | 15.9 | 7 | 5.1 | 1.9037 | 3734 | 43 |

| 25 | 24.9 | 7 | 6.4 | 1.2139 | 5370 | 68 |

| 35 | 34.3 | 7 | 7.5 | 0.8819 | 7389 | 94 |

| 50 | 49.5 | 7 | 9 | 0.6121 | 10662 | 135 |

| 120 | 117 | 19 | 14 | 0.2609 | 25186 | 321 |

| 150 | 148 | 19 | 15.8 | 0.2059 | 31900 | 406 |

| 185 | 182.3 | 19 | 17.5 | 0.1669 | 39386 | 502 |

Type Ankp GOST 839-80

| Nominal Cross Section | Calculated Corss Section | Number of Wires | Conductor Diameter | DC Resistance at 20 | Min. Breaking Load | Conductor Weight | Grease Weight |

| mm2 | mm2 | mm | Ω | N | kg/km | kg/km | |

| 16 | 15.9 | 7 | 5.1 | 1.9037 | 3734 | 43 | 0.5 |

| 25 | 24.9 | 7 | 6.4 | 1.2139 | 5370 | 68 | 0.5 |

| 35 | 34.3 | 7 | 7.5 | 0.8819 | 7389 | 94 | 0.5 |

| 50 | 49.5 | 7 | 9 | 0.6121 | 10662 | 135 | – |

| 120 | 117 | 19 | 14 | 0.2609 | 25186 | 321 | – |

| 150 | 148 | 19 | 15.8 | 0.2059 | 31900 | 406 | – |

| 185 | 182.3 | 19 | 17.5 | 0.1669 |

French Sizes NFC 34

| CODE NAME | AREA | NO. OF WIRES | DIAMETE OF IRES | OVERALL DIAMETER OF CONDUCTOR | TENSILE STRENGTH OF WIRE | RATED STRENGTH OF CONDUCTOR | MAXIMUM DC RESISTANCE AT 20ºC | LINEAR WEIGHT | ELASTICITY MODULUS* | COEFFICIENT OF LINEAR EXPANSION |

| mm2 | mm | mm | hbar | daN | km | kg/km | hbar | */oc | ||

| ASTER 22 | 21.99 | 7 | 2 | 6 | 32.4 | 710 | 1.5 | 60.2 | 6200 | 23.10-6 |

| ASTER 34.4 | 34.36 | 7 | 2.5 | 7.5 | 32.4 | 1105 | 0.958 | 94.1 | 6200 | 23.10-6 |

| ASTER 54.6 | 54.55 | 7 | 3.15 | 9.45 | 32.4 | 1755 | 0.603 | 149 | 6200 | 23.10-6 |

| ASTER 75.5 | 75.54 | 19 | 2.25 | 11.25 | 32.4 | 2430 | 0.438 | 208 | 6000 | 23.10-6 |

| ASTER 117 | 116.98 | 19 | 2.8 | 14 | 32.4 | 3765 | 0.283 | 322 | 6000 | 23.10-6 |

| ASTER 148 | 148.01 | 19 | 3.15 | 15.75 | 32.4 | 4765 | 0.224 | 407 | 6000 | 23.10-6 |

| ASTER 181.6 | 181.62 | 37 | 2.5 | 17.5 | 32.4 | 5845 | 0.183 | 500 | 5700 | 23.10-6 |

| ASTER 228 | 227.83 | 37 | 2.8 | 19.6 | 32.4 | 7340 | 0.146 | 627 | 5700 | 23.10-6 |

| ASTER 288 | 288.34 | 37 | 3.15 | 22.05 | 32.4 | 9280 | 0.115 | 794 | 5700 | 23.10-6 |

| ASTER 366 | 366.22 | 37 | 3.55 | 24.85 | 32.4 | 11785 | 0.0905 | 1009 | 5700 | 23.10-6 |

| ASTER 570 | 570.22 | 61 | 3.45 | 31.05 | 32.4 | 18360 | 0.0583 | 1574 | 5400 | 23.10-6 |

| ASTER 851 | 850.66 | 91 | 3.45 | 37.95 | 32.4 | 27390 | 0.0391 | 2354 | 5250 | 23.10-6 |

| ASTER 1144 | 1143.51 | 91 | 4 | 44 | 31.9 | 36260 | 0.0292 | 3164 | 5250 | 23.10-6 |

| ASTER 1600 | 1595.93 | 127 | 4 | 52 | 31.9 | 50640 | 0.0206 | 4425 | 5050 | 23.10-6 |