Application:

ACSR – The full name: Aluminum Conductor Steel Reinforced. Aluminum Conductor Steel Reinforced is used as bare overhead transmission cable and as primary and secondary distribution cable. This wire is suitable for use in all practical spans on wood poles, transmission towers, and other structures. Applications range from long, extra high voltage (EHV) transmission lines to sub-service spans at distribution or utilization voltages on private premises. ACSR offers optimal strength for line design. Variable steel core stranding for desired strength to be achieved without sacrificing ampacity.

ACSR (aluminum conductor steel reinforced) has a long service record because of its economy, dependability, and strength to weight ratio. The combined light weight and high conductivity of aluminum with strength of the steel core enables higher tensions, less sag, and longer spans than any alternative.

Conductor:

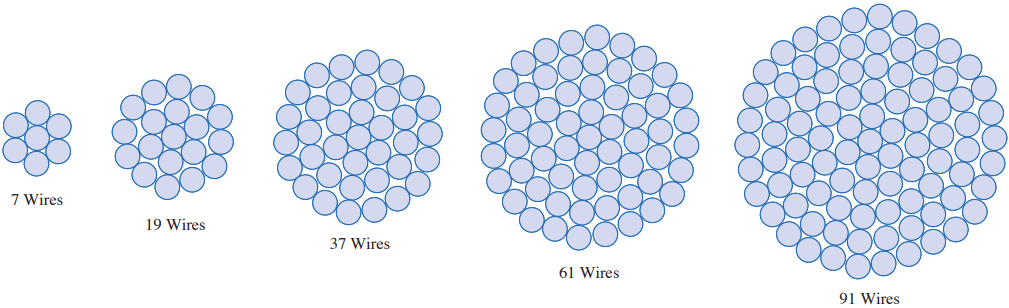

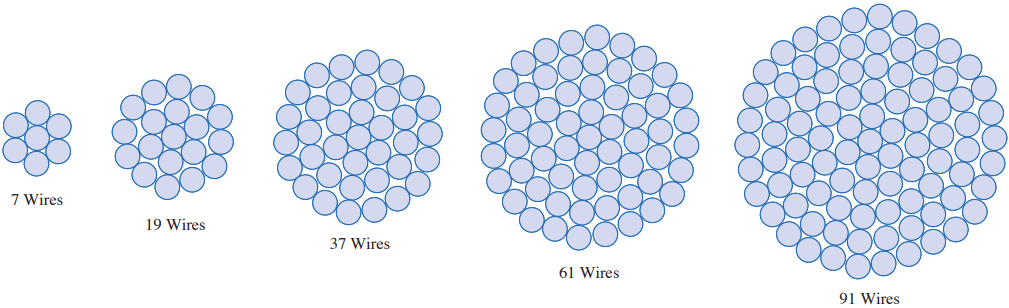

A solid or concentric stranded central steel core is surrounded by one or more layers of concentric stranded aluminum alloy 1350. The wire is protected from corrosion with a zinc coating.

The wire or wires which form the core, are made of galvanized steel and the external layer or layers, are of aluminium. Galvanized steel core consist normally of 1, 7 or 19 wires. The diameters of steel and aluminium wires can be the same, or different.

By varying the relative proportions of aluminium and steel, the required characteristics for any particular application can be reached. A higher U. T. S. Can be obtained, by increasing steel content, and a higher current carrying capacity by increasing aluminium content.

Standards:

1. American Standard&Canadian national standards-ASTM B 232/B 232M CSA C49

2. British Standards-BS 215-2 BS EN 50182

3. German Standards-DIN 48204

4. International Electrotechnical Commission International Standards-IEC 61089 A1/S1A A1/S2A A1/S3A

5. Japanese Industrial Standards-JIS C 3110

6. Russian National Standard-GOST 839-80

7. French Standard -NF C 34120

8. JIS C 3110

Parameter

ASTM B 232/B 232M CSA C49

BS 215-2 BS EN 50182

DIN 48204

IEC 61089 Characteristics of A1/S1A Conductors

IEC 61089 Characteristics of A1/S1B Conductors

IEC 61089 Characteristics of A1/S2A Conductors

IEC 61089 Characteristics of A1/S2B Conductors

Type AC GOST 839-80

NF C 34120

JIS C 3110

ACSR – The full name: Aluminum Conductor Steel Reinforced. Aluminum Conductor Steel Reinforced is used as bare overhead transmission cable and as primary and secondary distribution cable. This wire is suitable for use in all practical spans on wood poles, transmission towers, and other structures. Applications range from long, extra high voltage (EHV) transmission lines to sub-service spans at distribution or utilization voltages on private premises. ACSR offers optimal strength for line design. Variable steel core stranding for desired strength to be achieved without sacrificing ampacity.

ACSR (aluminum conductor steel reinforced) has a long service record because of its economy, dependability, and strength to weight ratio. The combined light weight and high conductivity of aluminum with strength of the steel core enables higher tensions, less sag, and longer spans than any alternative.

Conductor:

A solid or concentric stranded central steel core is surrounded by one or more layers of concentric stranded aluminum alloy 1350. The wire is protected from corrosion with a zinc coating.

The wire or wires which form the core, are made of galvanized steel and the external layer or layers, are of aluminium. Galvanized steel core consist normally of 1, 7 or 19 wires. The diameters of steel and aluminium wires can be the same, or different.

By varying the relative proportions of aluminium and steel, the required characteristics for any particular application can be reached. A higher U. T. S. Can be obtained, by increasing steel content, and a higher current carrying capacity by increasing aluminium content.

Standards:

1. American Standard&Canadian national standards-ASTM B 232/B 232M CSA C49

2. British Standards-BS 215-2 BS EN 50182

3. German Standards-DIN 48204

4. International Electrotechnical Commission International Standards-IEC 61089 A1/S1A A1/S2A A1/S3A

5. Japanese Industrial Standards-JIS C 3110

6. Russian National Standard-GOST 839-80

7. French Standard -NF C 34120

8. JIS C 3110

Parameter

ASTM B 232/B 232M CSA C49

| Code | KCMIL OR AWG | Stranding | Stranding | Total Section Area | Weight | Breaking Load | Electrical Resistance @20o | Current Rating* | ||||

| AL | Steel | AL | Steel | O.D. | ||||||||

| mm^2 | mm^2 | No.×mm | No.×mm | mm | mm^2 | Kg/Km | KN | Ω/Km | A | |||

| Wren | 8 | 8.37 | 1.39 | 6/1.33 | 1/1.33 | 3.99 | 9.76 | 33.8 | 3.29 | 3.43 | 48 | |

| Warbler | 7 | 10.55 | 1.77 | 6/1.50 | 1/1.50 | 4.5 | 12.32 | 42.8 | 4.14 | 2.72 | 60 | |

| Turkey | 6 | 13.3 | 2.22 | 6/1.68 | 1/1.68 | 5.04 | 15.52 | 53.6 | 5.19 | 2.1499 | 76 | |

| Thrush | 5 | 16.77 | 2.8 | 6/1.89 | 1/1.89 | 5.67 | 19.57 | 67.9 | 6.56 | 1.711 | 80 | |

| Swan | 4 | 21.18 | 3.53 | 6/2.12 | 1/2.12 | 6.36 | 24.71 | 85.3 | 7.83 | 1.3501 | 101 | |

| Swallow | 3 | 26.66 | 4.45 | 6/2.38 | 1/2.38 | 7.14 | 31.11 | 107.9 | 10 | 1.076 | 129 | |

| Swanate | 4 | 21.12 | 5.35 | 7/1.96 | 1/2.61 | 6.53 | 26.47 | 99.6 | 9.79 | 1.3539 | 102 | |

| Sparrow | 2 | 33.59 | 5.6 | 6/2.67 | 1/2.67 | 8.01 | 39.19 | 135.7 | 11.92 | 0.8512 | 135 | |

| Sparate | 2 | 33.54 | 8.55 | 7/2.47 | 1/3.30 | 8.24 | 42.09 | 158.7 | 15.08 | 0.8525 | 135 | |

| Robin | 1 | 42.41 | 7.07 | 6/3.00 | 1/3.00 | 9 | 49.48 | 171.1 | 14.86 | 0.6742 | 156 | |

| Raven | 1/0 | 53.52 | 8.92 | 6/3.37 | 1/3.37 | 10.11 | 62.44 | 216.1 | 18.33 | 0.5343 | 180 | |

| Quail | 2/0 | 67.33 | 11.22 | 6/3.78 | 1/3.78 | 11.34 | 78.55 | 272 | 22.46 | 0.4247 | 207 | |

| Pigeon | 3/0 | 85.12 | 14.19 | 6/4.25 | 1/4.25 | 12.75 | 99.31 | 343 | 28.02 | 0.3359 | 239 | |

| Penguin | 4/0 | 107.22 | 17.87 | 6/4.77 | 1/4.77 | 14.31 | 125.09 | 432.7 | 35.36 | 0.2667 | 275 | |

| Partridge | 266.8 | 134.87 | 21.99 | 26/2.57 | 7/2.00 | 16.28 | 156.86 | 545.9 | 47.15 | 0.2141 | 316 | |

| Owl | 266.8 | 135.2 | 17.6 | 6/5.36 | 7/1.79 | 16.09 | 152.8 | 509 | 42.3 | 0.2123 | 314 | |

| Waxwing | 266.8 | 134.98 | 7.5 | 18/3.09 | 1/3.09 | 15.45 | 142.48 | 430.2 | 29.8 | 0.2129 | 313 | |

| Piper | 300 | 152 | 35.5 | 30/2.54 | 7/2.54 | 17.78 | 187.5 | 698 | 67.8 | 0.1898 | 341 | |

| Ostrich | 300 | 152.19 | 24.71 | 26/2.73 | 7/2.12 | 17.28 | 176.9 | 613.4 | 53.38 | 0.1897 | 341 | |

| Phoebe | 300 | 152 | 8.5 | 18/3.28 | 1/3.28 | 16.4 | 160.5 | 485 | 35.2 | 0.1895 | 322 | |

| Merlin | 336.4 | 170.22 | 9.46 | 18/3.47 | 1/3.47 | 17.35 | 179.68 | 542.8 | 37.36 | 0.1688 | 361 | |

| Linnet | 336.4 | 170.55 | 27.83 | 26/2.89 | 7/2.25 | 18.31 | 198.38 | 687.5 | 59.16 | 0.1693 | 365 | |

| Oriole | 336.4 | 170.5 | 39.78 | 30/2.69 | 7/2.69 | 18.83 | 210.28 | 783.3 | 72.06 | 0.1698 | 367 | |

| Chickadee | 397.5 | 200.93 | 11.16 | 18/3.77 | 1/3.77 | 18.85 | 212.09 | 641.3 | 43.15 | 0.143 | 400 | |

| Brant | 397.5 | 201.56 | 26.13 | 24/3.27 | 7/2.18 | 19.62 | 227.69 | 761 | 61.83 | 0.1433 | 403 | |

| Ibis | 397.5 | 201.34 | 32.73 | 26/3.14 | 7/2.44 | 19.88 | 234.07 | 812.4 | 68.05 | 0.1434 | 404 | |

| Lark | 397.5 | 200.9 | 46.88 | 30/2.92 | 7/2.92 | 20.44 | 247.78 | 925.2 | 84.07 | 0.1441 | 406 | |

| Pelican | 477 | 242.31 | 13.46 | 18/4.14 | 1/4.14 | 20.7 | 255.77 | 769.7 | 51.15 | 0.1186 | 448 | |

| Flicker | 477 | 241.58 | 31.4 | 24/3.58 | 7/2.39 | 21.49 | 272.98 | 913.5 | 72.06 | 0.1195 | 450 | |

| Hawk | 477 | 241.65 | 39.19 | 26/3.44 | 7/2.67 | 21.77 | 280.84 | 975.1 | 81.84 | 0.1195 | 451 | |

| Hen | 477 | 241.27 | 56.3 | 30/3.20 | 7/3.20 | 22.4 | 297.57 | 1110.6 | 98.3 | 0.12 | 453 | |

| Toucan | 477 | 241.7 | 23.8 | 22/3.74 | 7/2.08 | 21.2 | 265.5 | 854 | 68.9 | 0.1193 | 421 | |

| Heron | 500 | 253.4 | 59.1 | 30/3.28 | 7/3.28 | 22.96 | 312.5 | 1163 | 108 | 0.1139 | 441 | |

| Osprey | 556.5 | 282.47 | 15.69 | 18/4.47 | 1/4.47 | 22.35 | 298.16 | 897.7 | 59.6 | 0.1017 | 492 | |

| Sapsucker | 556.5 | 282 | 27.6 | 22/4.04 | 7/2.24 | 22.88 | 309.6 | 995 | 78.8 | 0.1023 | 494 | |

| Parakeet | 556.5 | 282.31 | 36.6 | 24/3.87 | 7/2.58 | 23.22 | 318.91 | 1065.6 | 83.18 | 0.1023 | 495 | |

| Dove | 556.5 | 282.59 | 45.92 | 26/3.72 | 7/2.89 | 23.55 | 328.51 | 1138.6 | 94.3 | 0.1022 | 497 | |

| Eagle | 556.5 | 282.07 | 65.82 | 30/3.46 | 7/3.46 | 24.22 | 347.89 | 1295.6 | 114.76 | 0.1026 | 499 | |

| Peacock | 605 | 306.13 | 39.78 | 24/4.03 | 7/2.69 | 24.19 | 345.91 | 1158.9 | 90.74 | 0.0943 | 520 | |

| Squab | 605 | 305.83 | 49.81 | 26/3.87 | 7/3.01 | 24.51 | 355.64 | 1237 | 101.41 | 0.0944 | 521 | |

| Wood Duck | 605 | 307.06 | 71.65 | 30/3.61 | 7/3.61 | 25.27 | 378.71 | 1408.4 | 121.43 | 0.0943 | 525 | |

| DUCK | 605 | 306.6 | 39.7 | 54/2.69 | 7/2.69 | 24.21 | 346.3 | 1160 | 101 | 0.09435 | 524 | |

| Teal | 605 | 307.06 | 69.62 | 30/3.61 | 19/2.16 | 25.24 | 376.68 | 1396.6 | 124.54 | 0.0943 | 525 | |

| Egret | 636 | 322.3 | 73.5 | 30/3.70 | 19/2.22 | 25.9 | 395.8 | 1469 | 141 | 0.08955 | 532 | |

| Goose | 636 | 322.3 | 41.8 | 54/2.76 | 7/2.76 | 24.84 | 364.1 | 1220 | 104 | 0.08975 | 532 | |

| Goldfinch | 636 | 322.3 | 31.6 | 22/4.32 | 7/2.40 | 24.48 | 353.9 | 1138 | 89.3 | 0.08949 | 532 | |

| Kingbird | 636 | 323.01 | 17.95 | 18/4.78 | 1/4.78 | 23.9 | 340.96 | 1026.6 | 68.05 | 0.089 | 533 | |

| Swift | 636 | 323.02 | 8.97 | 36/3.38 | 1 /3.38 | 23.66 | 331.99 | 956.5 | 60.05 | 0.089 | 532 | |

| Rook | 636 | 323.07 | 41.88 | 24/4.14 | 7/2.76 | 24.84 | 364.95 | 1217.5 | 95.19 | 0.0894 | 537 | |

| Grosbeak | 636 | 321.84 | 52.49 | 26/3.97 | 7/3.09 | 25.15 | 374.33 | 1300.8 | 104.97 | 0.0897 | 537 | |

| Scoter | 636 | 322.56 | 75.26 | 30/3.70 | 7/3.70 | 25.9 | 397.82 | 1480.7 | 127.66 | 0.0897 | 541 | |

| Egret | 636 | 322.56 | 73.54 | 30/3.70 | 19/2.22 | 25.9 | 396.1 | 1469 | 130.77 | 0.0897 | 541 | |

| Flamingo | 666.6 | 337.27 | 43.72 | 24/4.23 | 7/2.82 | 25.38 | 380.99 | 1276.6 | 99.64 | 0.0856 | 551 | |

| Gannet | 666.6 | 338.26 | 54.9 | 26/4.07 | 7/3.16 | 25.76 | 393.16 | 1363.3 | 110.31 | 0.0854 | 553 | |

| Gull | 666.6 | 337.8 | 43.7 | 54/2.82 | 7/2.82 | 25.38 | 337.8 | 1278 | 109 | 0.08563 | 536 | |

| – | 666.6 | 337.8 | 17.4 | 42/3.20 | 7/1.78 | 24.54 | 337.8 | 10 | 7077.8 | 0.08552 | 536 | |

| Stilt | 715.5 | 363.27 | 46.88 | 24/4.39 | 7/2.92 | 26.32 | 410.15 | 1370.4 | 107.2 | 0.0795 | 576 | |

| Starling | 715.5 | 361.93 | 59.15 | 26/4.21 | 7/3.28 | 26.68 | 421.08 | 1463.7 | 118.32 | 0.0798 | 577 | |

| Redwing | 715.5 | 362.06 | 82.41 | 30/3.92 | 19/2.35 | 27.43 | 444.47 | 1650.6 | 143.23 | 0.0799 | 580 | |

| Crow | 715.5 | 362.6 | 46.8 | 54/2.92 | 7/2.92 | 26.28 | 362.6 | 1370 | 117 | 0.07978 | 548 | |

| – | 715.5 | 362.6 | 18.6 | 42/3.32 | 7/1.84 | 25.44 | 409.4 | 1148 | 83.6 | 0.07968 | 548 | |

| Coot | 795 | 401.86 | 11.16 | 36/3.77 | 1/3.77 | 26.39 | 413.02 | 1195.8 | 73.39 | 0.0715 | 607 | |

| Tern | 795 | 403.77 | 27.83 | 45/3.38 | 7/2.25 | 27.03 | 431.6 | 1331.8 | 94.3 | 0.0715 | 610 | |

| Condor | 795 | 402.33 | 52.15 | 54/3.08 | 7/3.08 | 27.72 | 454.48 | 1520.7 | 118.32 | 0.0718 | 612 | |

| Cuckoo | 795 | 402.33 | 52.15 | 24/4.62 | 7/3.08 | 27.72 | 454.48 | 1522.2 | 117.43 | 0.0718 | 612 | |

| Drake | 795 | 402.56 | 65.44 | 26/4.44 | 7/3.45 | 28.11 | 468 | 1626.4 | 131.66 | 0.0717 | 615 | |

| Macaw | 795 | 402.8 | 20.7 | 42/3.49 | 7/1.94 | 26.76 | 423.5 | 1276 | 92.5 | 0.07171 | 617 | |

| Mallard | 795 | 403.84 | 91.78 | 26/4.44 | 7/3.45 | 28.96 | 495.62 | 1836 | 159.24 | 0.0717 | 619 | |

| Crane | 874.5 | 443.1 | 57.4 | 54/3.23 | 7/3.23 | 29.07 | 443.1 | 1676 | 138 | 0.06527 | 638 | |

| – | 874.5 | 443.1 | 22.9 | 42/3.67 | 7/2.04 | 28.14 | 466 | 1404 | 102 | 0.06519 | 638 | |

| Ruddy | 900 | 455.5 | 31.67 | 45/3.59 | 7/2.40 | 28.74 | 487.17 | 1507.3 | 104.53 | 0.0634 | 656 | |

| – | 900 | 456 | 23.6 | 42/3.72 | 7/2.07 | 28.53 | 479.6 | 1554 | 105 | 0.06334 | 659 | |

| Canary | 900 | 456.28 | 59.15 | 54/3.28 | 7/3.28 | 29.52 | 515.43 | 1723.1 | 134.33 | 0.0633 | 660 | |

| Catbird | 954 | 484.61 | 13.46 | 36/4.14 | 1/4.14 | 28.98 | 498.07 | 1434.4 | 86.74 | 0.0593 | 679 | |

| Rail | 954 | 483.84 | 33.54 | 45/3.70 | 7/2.47 | 29.61 | 517.38 | 1598.1 | 110.76 | 0.0597 | 680 | |

| Cardinal | 954 | 484.53 | 62.81 | 54/3.38 | 7/3.38 | 30.42 | 547.34 | 1825.9 | 142.34 | 0.0596 | 685 | |

| Phoenix | 954 | 483.4 | 24.9 | 42/3.83 | 7/2.13 | 29.37 | 508.3 | 1532 | 109 | 0.05976 | 683 | |

| Cardinal | 954 | 484.53 | 62.81 | 54/3.38 | 7/3.38 | 30.42 | 547.34 | 1825.9 | 142.34 | 0.0596 | 685 | |

| Tanager | 522.79 | 14.52 | 36/4.30 | 1/4.30 | 30.1 | 537.31 | 1553.5 | 93.85 | 0.055 | 710 | ||

| Orotlan | 523.87 | 36.31 | 45/3.85 | 7/2.57 | 30.81 | 560.18 | 1730.5 | 118.32 | 0.0551 | 713 | ||

| Snowbird | 1033.5 | 523.7 | 26.8 | 42/3.98 | 7/2.21 | 30.51 | 550.5 | 1658 | 118 | 0.05516 | 718 | |

| Curlew | 1033.5 | 522.51 | 67.73 | 54/3.51 | 7/3.51 | 31.59 | 590.24 | 1977.6 | 153.9 | 0.0553 | 716 | |

| Bluejay | 565.49 | 38.9 | 45/4.00 | 7/2.66 | 31.98 | 604.39 | 1866 | 127.66 | 0.0511 | 745 | ||

| Beaumont | 1113 | 564 | 128.8 | 42/4.13 | 7/2.29 | 31.65 | 692.8 | 1785 | 126 | 0.05122 | 747 | |

| Finch | 1113 | 565.03 | 71.57 | 54/3.65 | 19/2.19 | 32.85 | 636.6 | 2127.8 | 164.58 | 0.0514 | 748 | |

| Bunting | 605.76 | 41.88 | 45/4.14 | 7/2.76 | 33.12 | 647.64 | 1996.9 | 136.55 | 0.0477 | 776 | ||

| – | 1192.5 | 604.3 | 31.1 | 42/4.28 | 7/2.38 | 32.82 | 635.4 | 1915 | 135 | 0.04781 | 779 | |

| Grackle | 1192.5 | 602.79 | 76.89 | 54/3.77 | 19/2.27 | 33.97 | 679.68 | 2278.1 | 176.59 | 0.0481 | 777 | |

| Skylark | 646.02 | 17.95 | 36/4.78 | 1/4.78 | 33.46 | 663.97 | 1913.6 | 115.65 | 0.0445 | 804 | ||

| Bittern | 644.4 | 44.66 | 45/4.27 | 7/2.85 | 34.17 | 689.06 | 2130.8 | 145.89 | 0.0448 | 805 | ||

| Pheasant | 1272 | 645.08 | 81.71 | 54/3.90 | 19/2.34 | 35.1 | 726.79 | 2431.4 | 183.26 | 0.045 | 808 | |

| Scissortail | 1272 | 644.5 | 33.3 | 42/4.42 | 7/2.46 | 33.9 | 677.8 | 2043 | 144 | 0.04482 | 786 | |

| Dipper | 684.24 | 47.2 | 45/4.40 | 7/2.93 | 35.19 | 731.44 | 2263.2 | 154.79 | 0.0422 | 834 | ||

| Martin | 1351.5 | 685.39 | 86.67 | 54/4.02 | 19/2.41 | 36.17 | 772.06 | 2581.7 | 194.82 | 0.0423 | 838 | |

| – | 1351.5 | 684.8 | 35.2 | 42/4.56 | 7/2.53 | 34.95 | 720 | 2169 | 153 | 0.04218 | 814 | |

| Bobolink | 725.27 | 50.14 | 45/4.53 | 7/3.02 | 36.24 | 775.41 | 2397.2 | 164.13 | 0.0398 | 862 | ||

| Plover | 1431 | 726.92 | 91.78 | 54/4.14 | 19/2.48 | 37.24 | 818.7 | 2734.9 | 206.39 | 0.0399 | 866 | |

| – | 1431 | 725.1 | 37.5 | 42/4.69 | 7/2.61 | 35.97 | 762.6 | 2298 | 162 | 0.03984 | 843 | |

| Nuthatch | 1510.5 | 764.2 | 52.83 | 45/4.65 | 7/3.10 | 37.2 | 817.03 | 2529.6 | 171.25 | 0.0378 | 888 | |

| Parrot | 1510.5 | 766.06 | 97.03 | 54/4.25 | 19/2.55 | 38.25 | 863.09 | 2883.7 | 217.51 | 0.0379 | 892 | |

| – | 1510.5 | 765.4 | 39.5 | 42/4.82 | 7/2.68 | 36.96 | 804.9 | 2425 | 171 | 0.03774 | 868 | |

| Lapwing | 1590 | 807.53 | 55.6 | 45/4.78 | 7/3.18 | 38.22 | 863.13 | 2663.5 | 180.14 | 0.0358 | 916 | |

| Falcon | 1590 | 806.23 | 102.43 | 54/4.36 | 19/2.62 | 39.26 | 908.66 | 3038.5 | 229.52 | 0.036 | 919 | |

| – | 1590 | 805.7 | 70.8 | 48/4.62 | 7/3.59 | 38.49 | 876.5 | 2783 | 211 | 0.03586 | 871 | |

| – | 1590 | 805.7 | 34.6 | 72/3.77 | 7/2.51 | 37.69 | 840.3 | 2501 | 172 | 0.0359 | 871 | |

| Chukar | 903.18 | 73.54 | 84/3.70 | 19/2.22 | 40.7 | 976.72 | 3083.1 | 217.51 | 0.0321 | 976 | ||

| Bluebird | 1092.84 | 88.84 | 84/4.07 | 19/2.44 | 44.76 | 1181.68 | 3731.9 | 256.65 | 0.0266 | 1083 | ||

| Kiwi | 1099.76 | 47.52 | 72/4.41 | 7/2.94 | 44.1 | 1147.28 | 3423.9 | 215.28 | 0.0264 | 1083 | ||

| Thrasher | 1171.42 | 63.94 | 76/4.43 | 19/2.07 | 45.79 | 1235.36 | 3754.2 | 243.75 | 0.0248 | 1122 | ||

| High Strength Stranding | ||||||||||||

| Grouse** | 40.54 | 14.12 | 8/2.54 | 1/4.24 | 9.32 | 54.66 | 221.4 | 21.75 | 0.7089 | 153 | ||

| Petrel** | 51.61 | 30.1 | 12/2.34 | 7/2.34 | 11.7 | 81.71 | 377.7 | 42.08 | 0.5595 | 181 | ||

| Minorca** | 56.11 | 32.73 | 12/2.44 | 7/2.44 | 12.2 | 88.84 | 411.1 | 45.81 | 0.5146 | 191 | ||

| Leghorn** | 68.2 | 39.78 | 12/2.69 | 7/2.69 | 13.45 | 107.98 | 499.2 | 55.16 | 0.4234 | 215 | ||

| Guinea** | 80.36 | 46.88 | 12/2.92 | 7/2.92 | 14.6 | 127.24 | 589.7 | 64.94 | 0.3593 | 238 | ||

| Dotterel** | 89.41 | 52.15 | 12/3.08 | 7/3.08 | 15.4 | 141.56 | 656.1 | 70.28 | 0.323 | 254 | ||

| Dorking** | 96.51 | 56.3 | 12/3.20 | 7/3.20 | 16 | 152.81 | 707.8 | 75.62 | 0.2992 | 267 | ||

| Cochin** | 107.04 | 62.44 | 12/3.37 | 7/3.37 | 16.85 | 169.48 | 783.9 | 84.07 | 0.2698 | 284 | ||

| Brahma*&** | 102.79 | 91.78 | 12/3.37 | 7/3.37 | 18.12 | 194.57 | 1003.8 | 114.76 | 0.2809 | 283 | ||

| Code Name | Area | Stranding | Approx. Overall Diameter | Weight | Nominal Breaking Load | D.C. Resistance at 20℃ | Standard Length | ||||||

| Nominal Alum. | Alum. | Steel | Total | Alum. | Steel | Alum. | Steel | Total | |||||

| mm2 | mm2 | mm2 | mm2 | mm | mm | mm | kg/km | kg/km | kg/km | kN | ohm/km | m±5% | |

| Mole | 10 | 10.62 | 1.77 | 12.39 | 6/1.50 | 1/1.50 | 4.5 | 29 | 14 | 43 | 4.14 | 2.076 | 3000 |

| Squirrel | 20 | 20.94 | 3.49 | 24.43 | 6/2.11 | 1/2.11 | 6.33 | 58 | 27 | 85 | 7.88 | 1.368 | 3000 |

| Gopher | 25 | 26.25 | 4.37 | 30.62 | 6/2.36 | 1/2.36 | 7.08 | 72 | 34 | 106 | 9.61 | 1.093 | 2500 |

| Weasel | 30 | 31.61 | 5.27 | 36.88 | 6/2.59 | 1/2.59 | 7.77 | 87 | 41 | 128 | 11.45 | 0.9077 | 2000 |

| Fox | 35 | 36.66 | 6.11 | 42.77 | 6/2.79 | 1/2.79 | 8.37 | 101 | 48 | 149 | 13.2 | 0.7822 | 2000 |

| Ferret | 40 | 42.41 | 7.07 | 49.48 | 6/3.00 | 1/3.00 | 9 | 117 | 55 | 172 | 15.2 | 0.6766 | 2500 |

| Rabbit | 50 | 52.88 | 8.82 | 61.7 | 6/3.35 | 1/3.35 | 10.05 | 145 | 69 | 214 | 18.35 | 0.5426 | 2000 |

| Mink | 60 | 63.18 | 10.53 | 73.71 | 6/3.66 | 1/3.66 | 10.98 | 173 | 82 | 255 | 21.8 | 0.4545 | 3000 |

| Skunk | 60 | 63.27 | 36.93 | 100.3 | 12/2.59 | 7/2.59 | 12.95 | 175 | 290 | 465 | 53 | 0.4567 | 2500 |

| Beaver | 70 | 74.82 | 12.47 | 87.29 | 6/3.99 | 1/3.99 | 11.97 | 205 | 97 | 302 | 25.7 | 0.3825 | 2500 |

| Horse | 70 | 73.37 | 42.8 | 116.17 | 12/2.79 | 7/2.79 | 13.95 | 203 | 335 | 538 | 61.2 | 0.3936 | 2000 |

| Racoon | 75 | 79.2 | 13.2 | 92.4 | 6/4.10 | 1/4.10 | 12.3 | 217 | 103 | 320 | 27.2 | 0.3622 | 2500 |

| Otter | 80 | 83.88 | 13.98 | 97.86 | 6/4.22 | 1/4.22 | 12.66 | 230 | 109 | 339 | 28.8 | 0.3419 | 2500 |

| Cat | 90 | 95.4 | 15.9 | 111.3 | 6/4.50 | 1/4.50 | 13.5 | 262 | 124 | 386 | 32.7 | 0.3007 | 2000 |

| Hare | 100 | 105 | 17.5 | 122.5 | 6/4.72 | 1/4.72 | 14.16 | 288 | 137 | 425 | 36 | 0.2733 | 2000 |

| Dog | 100 | 105 | 13.5 | 118.5 | 6/4.72 | 7/1.57 | 14.15 | 288 | 106 | 394 | 32.7 | 0.2733 | 2000 |

| Hyena | 100 | 105.8 | 20.44 | 126.2 | 7/4.39 | 7/1.93 | 14.57 | 290 | 160 | 450 | 40.9 | 0.2712 | 2000 |

| Leopard | 125 | 131.3 | 16.8 | 148.1 | 6/5.28 | 7/1.75 | 15.81 | 360 | 132 | 492 | 40.7 | 0.2184 | 2000 |

| Coyote | 125 | 132.1 | 20.1 | 152.2 | 26/2.54 | 7/1.91 | 15.89 | 365 | 157 | 522 | 46.4 | 0.2187 | 2000 |

| Cougar | 125 | 130.3 | 7.25 | 137.5 | 18/3.05 | 1/3.05 | 15.25 | 362 | 57 | 419 | 29.8 | 0.2189 | 2000 |

| Tiger | 125 | 131.1 | 30.6 | 161.7 | 30/2.36 | 7/2.36 | 16.52 | 362 | 240 | 602 | 58 | 0.2202 | 2500 |

| Wolf | 150 | 158 | 36.9 | 194.9 | 30/2.59 | 7/2.59 | 18.13 | 437 | 289 | 726 | 69.2 | 0.1828 | 2000 |

| Dingo | 150 | 158.7 | 8.8 | 167.5 | 18/3.35 | 1/3.35 | 16.75 | 437 | 69 | 506 | 35.7 | 0.1815 | 3000 |

| Lynx | 175 | 183.4 | 42.8 | 226.2 | 30/2.79 | 7/2.79 | 19.53 | 507 | 335 | 842 | 79.8 | 0.1576 | 2000 |

| Caracal | 175 | 184.2 | 10.3 | 194.5 | 18/3.61 | 1/3.61 | 18.05 | 507 | 80 | 587 | 41.1 | 0.1563 | 2500 |

| Panther | 200 | 212 | 49.5 | 261.5 | 30/3.00 | 7/3.00 | 21 | 586 | 388 | 974 | 92.25 | 0.1363 | 2500 |

| Lion | 225 | 238.5 | 55.6 | 294.2 | 30/3.18 | 7/3.18 | 22.26 | 659 | 436 | 1095 | 109.6 | 0.1212 | 2000 |

| Bear | 250 | 264 | 61.6 | 325.6 | 30/3.35 | 7/3.35 | 23.45 | 730 | 483 | 1213 | 111.1 | 0.1093 | 2000 |

| Goat | 300 | 324.3 | 75.7 | 400 | 30/3.71 | 7/3.71 | 25.97 | 896 | 593 | 1489 | 135.7 | 0.0891 | 3000 |

| Sheep | 350 | 374.1 | 87.3 | 461.4 | 30/3.99 | 7/3.99 | 27.93 | 1034 | 684 | 1718 | 155.9 | 0.07704 | 2500 |

| Antelope | 350 | 373.1 | 48.4 | 421.5 | 54/2.97 | 7/2.97 | 26.73 | 1032 | 379 | 1411 | 118.2 | 0.07727 | 2500 |

| Bison | 350 | 381.8 | 49.5 | 431.3 | 54/3.00 | 7/3.00 | 27 | 1056 | 388 | 1444 | 120.9 | 0.07573 | 3000 |

| Jaguar | 200 | 210.6 | 11.7 | 222.3 | 18/3.86 | 1/3.86 | 19.3 | 580 | 91 | 671 | 46.55 | 0.1367 | 2000 |

| Deer | 400 | 429.3 | 100.2 | 529.5 | 30/4.27 | 7/4.27 | 29.89 | 1186 | 785 | 1971 | 178.5 | 0.06726 | 2500 |

| Zebra | 400 | 428.9 | 55.6 | 484.5 | 54/3.18 | 7/3.18 | 28.62 | 1186 | 435 | 1621 | 131.9 | 0.0674 | 2000 |

| Elk | 450 | 477 | 111.3 | 588.3 | 30/4.50 | 7/4.50 | 31.5 | 1318 | 872 | 2190 | 198.2 | 0.06056 | 2000 |

| Camel | 450 | 475.2 | 61.6 | 536.8 | 54/3.35 | 7/3.35 | 30.15 | 1314 | 483 | 1797 | 145.7 | 0.06073 | 2500 |

| Moose | 500 | 528.7 | 68.5 | 597.2 | 54/3.53 | 7/3.53 | 31.77 | 1462 | 537 | 1999 | 161.1 | 0.0547 | 2000 |

| Area | Stranding and wire diameter | Overall Diameter | Linear mass | Nominal breaking load | Maximum resistance at 20 ℃ | ||||||

| Nominal | Actual | ||||||||||

| Al/St | Al | St | Total | Al | St | Al | St | Total | |||

| mm2 | mm2 | mm2 | mm2 | mm | mm | mm | kg/km | kg/km | kg/km | daN | ohm/km |

| 16/2.5 | 15.3 | 2.5 | 17.8 | 6/1.80 | 1/1.80 | 5.4 | 42 | 20 | 62 | 595 | 1.878 |

| 25/4.0 | 23.8 | 4 | 27.8 | 6/2.25 | 1/2.25 | 6.8 | 65 | 32 | 97 | 920 | 1.2002 |

| 36/6.0 | 34.3 | 5.7 | 40 | 6/2.70 | 1/2.70 | 8.1 | 94 | 46 | 140 | 1265 | 0.8352 |

| 44/32.0 | 44 | 31.7 | 75.7 | 14/2.00 | 7/2.40 | 11.2 | 122 | 250 | 372 | 4500 | 0.6573 |

| 50/8.0 | 48.3 | 8 | 56.3 | 6/3.20 | 1/3.20 | 9.6 | 132 | 64 | 196 | 1710 | 0.5946 |

| 50/30 | 51.2 | 29.8 | 81 | 12/2.33 | 7/2.33 | 11.7 | 141 | 237 | 378 | 4380 | 0.5643 |

| Dec-70 | 69.9 | 11.4 | 81.3 | 26/1.85 | 7/1.44 | 11.7 | 193 | 91 | 284 | 2680 | 0.413 |

| 95/15 | 94.4 | 15.3 | 109.7 | 26/2.15 | 7/1.67 | 13.6 | 260 | 123 | 383 | 3575 | 0.3058 |

| 95/55 | 96.5 | 56.3 | 152.8 | 12/3.20 | 7/3.20 | 16 | 266 | 446 | 712 | 7935 | 0.2992 |

| 105/75 | 105.7 | 75.5 | 181.5 | 14/3.10 | 9/2.25 | 17.5 | 292 | 599 | 891 | 10845 | 0.2735 |

| 120/20 | 121.06 | 19.8 | 141.4 | 26/2.44 | 7/1.90 | 15.5 | 336 | 158 | 494 | 4565 | 0.2374 |

| 120/70 | 122 | 71.3 | 193.3 | 12/3.6 | 7/3.60 | 18 | 337 | 564 | 901 | 10000 | 0.2364 |

| 125/30 | 127.9 | 29.8 | 157.7 | 30/2.33 | 7/2.33 | 16.3 | 353 | 238 | 591 | 5760 | 0.2259 |

| 150/25 | 148.9 | 24.2 | 173.1 | 26/2.70 | 7/2.10 | 17.1 | 411 | 194 | 605 | 5525 | 0.1939 |

| 170/40 | 171.8 | 40.1 | 211.9 | 30/2.70 | 7/2.70 | 18.9 | 475 | 319 | 794 | 7675 | 0.1682 |

| 185/30 | 183.8 | 29.8 | 213.6 | 26/3.00 | 7/2.33 | 19 | 507 | 239 | 746 | 6620 | 0.1571 |

| 210/35 | 209.1 | 34.1 | 243.2 | 26/3.20 | 7/2.49 | 20.3 | 577 | 273 | 850 | 7490 | 0.138 |

| 210/50 | 212.1 | 49.5 | 261.6 | 30/3.00 | 7/3.00 | 21 | 587 | 394 | 981 | 9390 | 0.1362 |

| 230/30 | 230.9 | 29.8 | 260.7 | 24/3.50 | 7/2.33 | 21 | 638 | 239 | 877 | 7310 | 0.1249 |

| 240/40 | 243 | 39.5 | 282.5 | 26/3.45 | 7/2.68 | 21.9 | 671 | 316 | 987 | 8640 | 0.1188 |

| 265/35 | 263.7 | 34.1 | 297.8 | 24/3.74 | 7/2.49 | 22.4 | 728 | 274 | 1002 | 8305 | 0.1094 |

| 300/50 | 304.3 | 49.5 | 353.7 | 26/3.86 | 7/3.00 | 24.5 | 840 | 396 | 1236 | 10700 | 0.09487 |

| 305/40 | 304.6 | 39.5 | 344.1 | 54/2.68 | 7/2.68 | 24.1 | 843 | 317 | 1160 | 9940 | 0.0949 |

| 340/30 | 339.3 | 29.8 | 369.1 | 48/3.00 | 7/2.33 | 25 | 938 | 242 | 1180 | 9290 | 0.08509 |

| 380/50 | 382 | 49.5 | 431.5 | 54/3.00 | 7/3.00 | 27 | 1056 | 397 | 1453 | 12310 | 0.08509 |

| 385/35 | 386 | 34.1 | 420.1 | 48/3.20 | 7/2.49 | 26.7 | 1067 | 277 | 1344 | 10480 | 0.07573 |

| 435/55 | 434.03 | 59.3 | 490.6 | 54/3.20 | 7/3.20 | 28.8 | 1203 | 450 | 1653 | 13645 | 0.07478 |

| 450/40 | 448.7 | 39.5 | 488.2 | 48/3.45 | 7/2.68 | 28.7 | 1241 | 320 | 1561 | 12075 | 0.06656 |

| 490/65 | 490.3 | 63.6 | 553.9 | 54/3.40 | 7/3.40 | 30.6 | 1356 | 510 | 1866 | 15310 | 0.06434 |

| 495/35 | 494.1 | 34.1 | 528.2 | 45/3.74 | 7/2.49 | 29.9 | 1363 | 283 | 1646 | 12180 | 0.05846 |

| 510/45 | 510.2 | 45.3 | 555.5 | 48/3.68 | 7/2.87 | 30.7 | 1413 | 365 | 1778 | 13665 | 0.05655 |

| 550/70 | 550 | 71.3 | 621.3 | 54/3.60 | 7/3.60 | 32.4 | 1520 | 572 | 2092 | 17060 | 0.05259 |

| 560/50 | 561.7 | 49.5 | 611.2 | 48/3.86 | 7/3.00 | 32.2 | 1553 | 401 | 1954 | 14895 | 0.0514 |

| 570/40 | 565.5 | 39.5 | 610.3 | 45/4.00 | 7/2.68 | 32.2 | 1563 | 325 | 1888 | 13900 | 0.05108 |

| 650/45 | 698.8 | 45.3 | 653.49 | 45/4.30 | 7/2.87 | 34.4 | 1791 | 372 | 2163 | 15552 | 0.0442 |

| 680/85 | 678.8 | 86 | 764.8 | 54/4.00 | 18/2.40 | 36 | 1866 | 702 | 2570 | 21040 | 0.0426 |

| 1045/45 | 1045.58 | 45.3 | 1090.9 | 72/4.30 | 7/2.87 | 43 | 2879 | 370 | 3249 | 21787 | 0.0277 |

| Code Number | Steel Ratio | Areas | No. of Wires | Wire Dia. | Diameter | Linear Mass | Rated Strength | C. Resistance at 20℃ | |||||

| Alum. | Steel | Total | Alum. | Steel | Alum. | Steel | Core | Cond | |||||

| % | mm2 | mm2 | mm2 | mm | mm | mm | mm | kg/km | kN | ohm/km | |||

| 16 | 17 | 16 | 2.67 | 18.7 | 6 | 1 | 1.84 | 1.84 | 1.84 | 5.53 | 64.6 | 6.08 | 1.7934 |

| 25 | 17 | 25 | 4.17 | 29.2 | 6 | 1 | 2.3 | 2.3 | 2.3 | 6.91 | 100.9 | 9.13 | 1.1478 |

| 40 | 17 | 40 | 6.67 | 46.7 | 6 | 1 | 2.91 | 2.91 | 2.91 | 8.74 | 161.5 | 14.4 | 0.7174 |

| 63 | 17 | 63 | 10.5 | 73.5 | 6 | 1 | 3.66 | 3.66 | 3.66 | 11 | 254.4 | 21.63 | 0.4555 |

| 100 | 17 | 100 | 16.7 | 117 | 6 | 1 | 4.61 | 4.61 | 4.61 | 13.8 | 403.8 | 34.33 | 0.2869 |

| 125 | 6 | 125 | 6.94 | 132 | 18 | 1 | 2.97 | 2.97 | 2.97 | 14.9 | 397.9 | 29.17 | 0.2304 |

| 125 | 16 | 125 | 20.4 | 145 | 26 | 7 | 2.47 | 1.92 | 5.77 | 15.7 | 503.9 | 45.69 | 0.231 |

| 160 | 6 | 160 | 8.89 | 169 | 18 | 1 | 3.36 | 3.36 | 3.36 | 16.8 | 509.3 | 36.18 | 0.18 |

| 160 | 16 | 160 | 26.1 | 186 | 26 | 7 | 2.8 | 2.18 | 6.53 | 17.7 | 644.9 | 57.69 | 0.1805 |

| 200 | 6 | 200 | 11.1 | 211 | 18 | 1 | 3.76 | 3.76 | 3.76 | 18.8 | 636.7 | 44.22 | 0.144 |

| 200 | 16 | 200 | 32.6 | 233 | 26 | 7 | 3.13 | 2.43 | 7.3 | 19.8 | 806.2 | 70.13 | 0.1444 |

| 250 | 10 | 250 | 24.6 | 275 | 22 | 7 | 3.8 | 2.11 | 6.34 | 21.6 | 880.6 | 68.72 | 0.1154 |

| 250 | 16 | 250 | 40.7 | 291 | 26 | 7 | 3.5 | 2.72 | 8.16 | 22.2 | 1007.7 | 87.67 | 0.1155 |

| 315 | 7 | 315 | 21.8 | 337 | 45 | 7 | 2.99 | 1.99 | 5.97 | 23.9 | 1039.6 | 79.03 | 0.0917 |

| 315 | 16 | 315 | 51.3 | 366 | 26 | 7 | 3.93 | 3.05 | 9.16 | 24.9 | 1269.7 | 106.83 | 0.0917 |

| 400 | 7 | 400 | 27.7 | 428 | 45 | 7 | 3.36 | 2.24 | 6.73 | 26.9 | 1320.1 | 98.36 | 0.0722 |

| 400 | 13 | 400 | 51.9 | 452 | 54 | 7 | 3.07 | 3.07 | 9.21 | 27.6 | 1510.3 | 123.04 | 0.0723 |

| 450 | 7 | 450 | 31.1 | 481 | 45 | 7 | 3.57 | 2.38 | 7.14 | 28.5 | 1485.2 | 107.47 | 0.0642 |

| 450 | 13 | 450 | 58.3 | 508 | 54 | 7 | 3.26 | 3.26 | 9.77 | 29.3 | 1699.1 | 138.42 | 0.0643 |

| 500 | 7 | 500 | 34.6 | 535 | 45 | 7 | 3.76 | 2.51 | 7.52 | 30.1 | 1650.2 | 119.41 | 0.0578 |

| 500 | 13 | 500 | 64.8 | 565 | 54 | 7 | 3.43 | 3.43 | 10.3 | 30.9 | 1887.9 | 153.8 | 0.0578 |

| 560 | 7 | 560 | 38.7 | 599 | 45 | 7 | 3.98 | 2.65 | 7.96 | 31.8 | 1848.2 | 133.74 | 0.0516 |

| 560 | 13 | 560 | 70.9 | 631 | 54 | 19 | 3.63 | 2.18 | 10.9 | 32.7 | 2103.4 | 172.59 | 0.0516 |

| 630 | 7 | 630 | 43.6 | 674 | 45 | 7 | 4.22 | 2.81 | 8.44 | 33.8 | 2079.2 | 150.45 | 0.0459 |

| 630 | 13 | 630 | 79.8 | 710 | 54 | 19 | 3.85 | 2.31 | 11.6 | 34.7 | 2366.3 | 191.77 | 0.0459 |

| 710 | 7 | 710 | 49.1 | 759 | 45 | 7 | 4.48 | 2.99 | 8.96 | 35.9 | 2343.2 | 169.56 | 0.0407 |

| 710 | 13 | 710 | 89.9 | 800 | 54 | 19 | 4.09 | 2.45 | 12.3 | 36.8 | 2666.8 | 216.12 | 0.0407 |

| 800 | 4 | 800 | 34.6 | 835 | 72 | 7 | 3.76 | 2.51 | 7.52 | 37.6 | 2480.2 | 167.41 | 0.0361 |

| 800 | 8 | 800 | 66.7 | 867 | 84 | 7 | 3.48 | 3.48 | 10.4 | 38.3 | 2732.7 | 205.33 | 0.0362 |

| 800 | 13 | 800 | 101 | 901 | 54 | 19 | 4.44 | 2.61 | 13 | 39.1 | 3004.9 | 243.52 | 0.0362 |

| 900 | 4 | 900 | 38.9 | 939 | 72 | 7 | 3.99 | 2.66 | 7.98 | 39.9 | 2790.2 | 188.33 | 0.0321 |

| 900 | 8 | 900 | 75 | 975 | 84 | 7 | 3.69 | 3.69 | 11.1 | 40.6 | 3074.2 | 226.5 | 0.0322 |

| 1000 | 4 | 1000 | 43.2 | 1043 | 72 | 7 | 4.21 | 2.8 | 8.41 | 42.1 | 3100.3 | 209.26 | 0.0289 |

| 1120 | 4 | 1120 | 47.3 | 1167 | 72 | 19 | 4.45 | 1.78 | 8.9 | 44.5 | 3464.9 | 234.53 | 0.0258 |

| 1120 | 8 | 1120 | 91.2 | 1211 | 84 | 19 | 4.12 | 2.47 | 12.4 | 45.3 | 3811.5 | 283.17 | 0.0258 |

| 1250 | 8 | 1250 | 102 | 1352 | 84 | 19 | 4.35 | 2.61 | 13.1 | 47.9 | 4253.9 | 316.04 | 0.0232 |

| 1250 | 4 | 1250 | 52.8 | 1303 | 72 | 19 | 4.7 | 1.88 | 9.4 | 47 | 3867.1 | 261.75 | 0.0231 |

| Code Number | Steel Ratio | Areas | No. of Wires | Wire Dia. | Diameter | Linear Mass | Rated Strength | C. Resistance at 20℃ | |||||

| Alum. | Steel | Total | Alum. | Steel | Alum. | Steel | Core | Cond | |||||

| % | mm2 | mm2 | mm2 | mm | mm | mm | mm | kg/km | kN | ohm/km | |||

| 16 | 17 | 16 | 2.67 | 18.7 | 6 | 1 | 1.84 | 1.84 | 1.84 | 5.53 | 64.6 | 5.89 | 1.7934 |

| 25 | 17 | 25 | 4.17 | 29.2 | 6 | 1 | 2.3 | 2.3 | 2.3 | 6.91 | 100.9 | 8.83 | 1.1478 |

| 40 | 17 | 40 | 6.67 | 46.7 | 6 | 1 | 2.91 | 2.91 | 2.91 | 8.74 | 161.5 | 13.93 | 0.7174 |

| 63 | 17 | 63 | 10.5 | 73.5 | 6 | 1 | 3.66 | 3.66 | 3.66 | 11 | 254.4 | 20.58 | 0.4555 |

| 100 | 17 | 100 | 16.7 | 117 | 6 | 1 | 4.61 | 4.61 | 4.61 | 13.8 | 403.8 | 32.67 | 0.2869 |

| 125 | 6 | 125 | 6.94 | 132 | 18 | 1 | 2.97 | 2.97 | 2.97 | 14.9 | 397.9 | 28.68 | 0.2304 |

| 125 | 16 | 125 | 20.4 | 145 | 26 | 7 | 2.47 | 1.92 | 5.77 | 15.7 | 503.9 | 44.27 | 0.231 |

| 160 | 6 | 160 | 8.89 | 169 | 18 | 1 | 3.36 | 3.36 | 3.36 | 16.8 | 509.3 | 35.29 | 0.18 |

| 160 | 16 | 160 | 26.1 | 186 | 26 | 7 | 2.8 | 2.18 | 6.53 | 17.7 | 644.9 | 55.86 | 0.1805 |

| 200 | 6 | 200 | 11.1 | 211 | 18 | 1 | 3.76 | 3.76 | 3.76 | 18.8 | 636.7 | 43.11 | 0.144 |

| 200 | 16 | 200 | 32.6 | 233 | 26 | 7 | 3.13 | 2.43 | 7.3 | 19.8 | 806.2 | 67.85 | 0.1444 |

| 250 | 10 | 250 | 24.6 | 275 | 22 | 7 | 3.8 | 2.11 | 6.34 | 21.6 | 880.6 | 67.01 | 0.1154 |

| 250 | 16 | 250 | 40.7 | 291 | 26 | 7 | 3.5 | 2.72 | 8.16 | 22.2 | 1007.7 | 84.82 | 0.1155 |

| 315 | 7 | 315 | 21.8 | 337 | 45 | 7 | 2.99 | 1.99 | 5.97 | 23.9 | 1039.6 | 77.51 | 0.0917 |

| 315 | 16 | 315 | 51.3 | 366 | 26 | 7 | 3.93 | 3.05 | 9.16 | 24.9 | 1269.7 | 101.7 | 0.0917 |

| 400 | 7 | 400 | 27.7 | 428 | 45 | 7 | 3.36 | 2.24 | 6.73 | 26.9 | 1320.1 | 96.42 | 0.0722 |

| 400 | 13 | 400 | 51.9 | 452 | 54 | 7 | 3.07 | 3.07 | 9.21 | 27.6 | 1510.3 | 117.85 | 0.0723 |

| 450 | 7 | 450 | 31.1 | 481 | 45 | 7 | 3.57 | 2.38 | 7.14 | 28.5 | 1485.2 | 105.29 | 0.0642 |

| 450 | 13 | 450 | 58.3 | 508 | 54 | 7 | 3.26 | 3.26 | 9.77 | 29.3 | 1699.1 | 132.58 | 0.0643 |

| 500 | 7 | 500 | 34.6 | 535 | 45 | 7 | 3.76 | 2.51 | 7.52 | 30.1 | 1650.2 | 116.99 | 0.0578 |

| 500 | 13 | 500 | 64.8 | 565 | 54 | 7 | 3.43 | 3.43 | 10.3 | 30.9 | 1887.9 | 147.31 | 0.0578 |

| 560 | 7 | 560 | 38.7 | 599 | 45 | 7 | 3.98 | 2.65 | 7.96 | 31.8 | 1848.2 | 131.03 | 0.0516 |

| 560 | 13 | 560 | 70.9 | 631 | 54 | 19 | 3.63 | 2.18 | 10.9 | 32.7 | 2103.4 | 167.63 | 0.0516 |

| 630 | 7 | 630 | 43.6 | 674 | 45 | 7 | 4.22 | 2.81 | 8.44 | 33.8 | 2079.2 | 147.4 | 0.0459 |

| 630 | 13 | 630 | 79.8 | 710 | 54 | 19 | 3.85 | 2.31 | 11.6 | 34.7 | 2366.3 | 186.19 | 0.0459 |

| 710 | 7 | 710 | 49.1 | 759 | 45 | 7 | 4.48 | 2.99 | 8.96 | 35.9 | 2343.2 | 166.12 | 0.0407 |

| 710 | 13 | 710 | 89.9 | 800 | 54 | 19 | 4.09 | 2.45 | 12.3 | 36.8 | 2666.8 | 209.83 | 0.0407 |

| 800 | 4 | 800 | 34.6 | 835 | 72 | 7 | 3.76 | 2.51 | 7.52 | 37.6 | 2480.2 | 164.99 | 0.0361 |

| 800 | 8 | 800 | 66.7 | 867 | 84 | 7 | 3.48 | 3.48 | 10.4 | 38.3 | 2732.7 | 198.67 | 0.0362 |

| 800 | 13 | 800 | 101 | 901 | 54 | 19 | 4.44 | 2.61 | 13 | 39.1 | 3004.9 | 236.43 | 0.0362 |

| 900 | 4 | 900 | 38.9 | 939 | 72 | 7 | 3.99 | 2.66 | 7.98 | 39.9 | 2790.2 | 185.61 | 0.0321 |

| 900 | 8 | 900 | 75 | 975 | 84 | 7 | 3.69 | 3.69 | 11.1 | 40.6 | 3074.2 | 219 | 0.0322 |

| 1000 | 4 | 1000 | 43.2 | 1043 | 72 | 7 | 4.21 | 2.8 | 8.41 | 42.1 | 3100.3 | 206.23 | 0.0289 |

| 1120 | 4 | 1120 | 47.3 | 1167 | 72 | 19 | 4.45 | 1.78 | 8.9 | 44.5 | 3464.9 | 231.22 | 0.0258 |

| 1120 | 8 | 1120 | 91.2 | 1211 | 84 | 19 | 4.12 | 2.47 | 12.4 | 45.3 | 3811.5 | 276.78 | 0.0258 |

| 1250 | 8 | 1250 | 52.8 | 1303 | 72 | 19 | 4.35 | 2.61 | 13.1 | 47.9 | 4253.9 | 258.06 | 0.0231 |

| 1250 | 4 | 1250 | 102 | 1352 | 84 | 19 | 4.7 | 1.88 | 9.4 | 47 | 3867.1 | 308.91 | 0.0232 |

| Code Number | Steel Ratio | Areas | No. of Wires | Wire Dia. | Diameter | Linear Mass | Rated Strength | D.C. Resistance at 20℃ | |||||

| Alum. | Steel | Total | Alum. | Steel | Alum. | Steel | Core | Cond | |||||

| % | mm2 | mm2 | mm2 | mm | mm | mm | mm | kg/km | kN | ohm/km | |||

| 16 | 17 | 16 | 2.67 | 18.7 | 6 | 1 | 1.84 | 1.84 | 1.84 | 5.53 | 64.6 | 6.45 | 1.7934 |

| 25 | 17 | 25 | 4.17 | 29.2 | 6 | 1 | 2.3 | 2.3 | 2.3 | 6.91 | 100.9 | 9.71 | 1.1478 |

| 40 | 17 | 40 | 6.67 | 46.7 | 6 | 1 | 2.91 | 2.91 | 2.91 | 8.74 | 161.5 | 15.33 | 0.7174 |

| 63 | 17 | 63 | 10.5 | 73.5 | 6 | 1 | 3.66 | 3.66 | 3.66 | 11 | 254.4 | 22.37 | 0.4555 |

| 100 | 17 | 100 | 16.7 | 117 | 6 | 1 | 4.61 | 4.61 | 4.61 | 13.8 | 403.8 | 35.5 | 0.2869 |

| 125 | 6 | 125 | 6.94 | 132 | 18 | 1 | 2.97 | 2.97 | 2.97 | 14.9 | 397.9 | 30.14 | 0.2304 |

| 125 | 16 | 125 | 20.4 | 145 | 26 | 7 | 2.47 | 1.92 | 5.77 | 15.7 | 503.9 | 48.54 | 0.231 |

| 160 | 6 | 160 | 8.89 | 169 | 18 | 1 | 3.36 | 3.36 | 3.36 | 16.8 | 509.3 | 37.42 | 0.18 |

| 160 | 16 | 160 | 26.1 | 186 | 26 | 7 | 2.8 | 2.18 | 6.53 | 17.7 | 644.9 | 61.34 | 0.1805 |

| 200 | 6 | 200 | 11.1 | 211 | 18 | 1 | 3.76 | 3.76 | 3.76 | 18.8 | 636.7 | 45 | 0.144 |

| 200 | 16 | 200 | 32.6 | 233 | 26 | 7 | 3.13 | 2.43 | 7.3 | 19.8 | 806.2 | 74.69 | 0.1444 |

| 250 | 10 | 250 | 24.6 | 275 | 22 | 7 | 3.8 | 2.11 | 6.34 | 21.6 | 880.6 | 72.16 | 0.1154 |

| 250 | 16 | 250 | 40.7 | 291 | 26 | 7 | 3.5 | 2.72 | 8.16 | 22.2 | 1007.7 | 93.37 | 0.1155 |

| 315 | 7 | 315 | 21.8 | 337 | 45 | 7 | 2.99 | 1.99 | 5.97 | 23.9 | 1039.6 | 82.08 | 0.0917 |

| 315 | 16 | 315 | 51.3 | 366 | 26 | 7 | 3.93 | 3.05 | 9.16 | 24.9 | 1269.7 | 114.02 | 0.0917 |

| 400 | 7 | 400 | 27.7 | 428 | 45 | 7 | 3.36 | 2.24 | 6.73 | 26.9 | 1320.1 | 102.23 | 0.0722 |

| 400 | 13 | 400 | 51.9 | 452 | 54 | 7 | 3.07 | 3.07 | 9.21 | 27.6 | 1510.3 | 130.3 | 0.0723 |

| 450 | 7 | 450 | 31.1 | 481 | 45 | 7 | 3.57 | 2.38 | 7.14 | 28.5 | 1485.2 | 111.82 | 0.0642 |

| 450 | 13 | 450 | 58.3 | 508 | 54 | 7 | 3.26 | 3.26 | 9.77 | 29.3 | 1699.1 | 146.58 | 0.0643 |

| 500 | 7 | 500 | 34.6 | 535 | 45 | 7 | 3.76 | 2.51 | 7.52 | 30.1 | 1650.2 | 124.25 | 0.0578 |

| 500 | 13 | 500 | 64.8 | 565 | 54 | 7 | 3.43 | 3.43 | 10.3 | 30.9 | 1887.9 | 162.87 | 0.0578 |

| 560 | 7 | 560 | 38.7 | 599 | 45 | 7 | 3.98 | 2.65 | 7.96 | 31.8 | 1848.2 | 139.16 | 0.0516 |

| 560 | 13 | 560 | 70.9 | 631 | 54 | 19 | 3.63 | 2.18 | 10.9 | 32.7 | 2103.4 | 182.52 | 0.0516 |

| 630 | 7 | 630 | 43.6 | 674 | 45 | 7 | 4.22 | 2.81 | 8.44 | 33.8 | 2079.2 | 156.55 | 0.0459 |

| 630 | 13 | 630 | 79.8 | 710 | 54 | 19 | 3.85 | 2.31 | 11.6 | 34.7 | 2366.3 | 202.94 | 0.0459 |

| 710 | 7 | 710 | 49.1 | 759 | 45 | 7 | 4.48 | 2.99 | 8.96 | 35.9 | 2343.2 | 176.43 | 0.0407 |

| 710 | 13 | 710 | 89.9 | 800 | 54 | 19 | 4.09 | 2.45 | 12.3 | 36.8 | 2666.8 | 228.71 | 0.0407 |

| 800 | 4 | 800 | 34.6 | 835 | 72 | 7 | 3.76 | 2.51 | 7.52 | 37.6 | 2480.2 | 172.25 | 0.0361 |

| 800 | 8 | 800 | 66.7 | 867 | 84 | 7 | 3.48 | 3.48 | 10.4 | 38.3 | 2732.7 | 214.67 | 0.0362 |

| 800 | 13 | 800 | 101 | 901 | 54 | 19 | 4.44 | 2.61 | 13 | 39.1 | 3004.9 | 257.71 | 0.0362 |

| 900 | 4 | 900 | 38.9 | 939 | 72 | 7 | 3.99 | 2.66 | 7.98 | 39.9 | 2790.2 | 193.78 | 0.0321 |

| 900 | 8 | 900 | 75 | 975 | 84 | 7 | 3.69 | 3.69 | 11.1 | 40.6 | 3074.2 | 231.75 | 0.0322 |

| 1000 | 4 | 1000 | 43.2 | 1043 | 72 | 7 | 4.21 | 2.8 | 8.41 | 42.1 | 3100.3 | 215.31 | 0.0289 |

| 1120 | 4 | 1120 | 47.3 | 1167 | 72 | 19 | 4.45 | 1.78 | 8.9 | 44.5 | 3464.9 | 241.15 | 0.0258 |

| 1120 | 8 | 1120 | 91.2 | 1211 | 84 | 19 | 4.12 | 2.47 | 12.4 | 45.3 | 3811.5 | 295.94 | 0.0258 |

| 1250 | 4 | 1250 | 52.8 | 1303 | 72 | 19 | 4.7 | 1.88 | 9.4 | 47 | 3867.1 | 269.14 | 0.0231 |

| 1250 | 8 | 1250 | 102 | 1352 | 84 | 19 | 4.35 | 2.61 | 13.1 | 47.9 | 4253.9 | 330.29 | 0.0232 |

| Code Number | Steel Ratio | Areas | No. of Wires | Wire Dia. | Diameter | Linear Mass | Rated Strength | D.C. Resistance at 20℃ | |||||

| Alum. | Steel | Total | Alum. | Steel | Alum. | Steel | Core | Cond | |||||

| % | mm2 | mm2 | mm2 | mm | mm | mm | mm | kg/km | kN | ohm/km | |||

| 16 | 17 | 16 | 2.67 | 18.7 | 6 | 1 | 1.84 | 1.84 | 1.84 | 5.53 | 64.6 | 6.27 | 1.7934 |

| 25 | 17 | 25 | 4.17 | 29.2 | 6 | 1 | 2.3 | 2.3 | 2.3 | 6.91 | 100.9 | 9.42 | 1.1478 |

| 40 | 17 | 40 | 6.67 | 46.7 | 6 | 1 | 2.91 | 2.91 | 2.91 | 8.74 | 161.5 | 14.87 | 0.7174 |

| 63 | 17 | 63 | 10.5 | 73.5 | 6 | 1 | 3.66 | 3.66 | 3.66 | 11 | 254.4 | 21.63 | 0.4555 |

| 100 | 17 | 100 | 16.7 | 117 | 6 | 1 | 4.61 | 4.61 | 4.61 | 13.8 | 403.8 | 34.33 | 0.2869 |

| 125 | 6 | 125 | 6.94 | 132 | 18 | 1 | 2.97 | 2.97 | 2.97 | 14.9 | 397.9 | 29.65 | 0.2304 |

| 125 | 16 | 125 | 20.4 | 145 | 26 | 7 | 2.47 | 1.92 | 5.77 | 15.7 | 503.9 | 47.12 | 0.231 |

| 160 | 6 | 160 | 8.89 | 169 | 18 | 1 | 3.36 | 3.36 | 3.36 | 16.8 | 509.3 | 36.8 | 0.18 |

| 160 | 16 | 160 | 26.1 | 186 | 26 | 7 | 2.8 | 2.18 | 6.53 | 17.7 | 644.9 | 59.51 | 0.1805 |

| 200 | 6 | 200 | 11.1 | 211 | 18 | 1 | 3.76 | 3.76 | 3.76 | 18.8 | 636.7 | 44.22 | 0.144 |

| 200 | 16 | 200 | 32.6 | 233 | 26 | 7 | 3.13 | 2.43 | 7.3 | 19.8 | 806.2 | 72.41 | 0.1444 |

| 250 | 10 | 250 | 24.6 | 275 | 22 | 7 | 3.8 | 2.11 | 6.34 | 21.6 | 880.6 | 70.44 | 0.1154 |

| 250 | 16 | 250 | 40.7 | 291 | 26 | 7 | 3.5 | 2.72 | 8.16 | 22.2 | 1007.7 | 90.52 | 0.1155 |

| 315 | 7 | 315 | 21.8 | 337 | 45 | 7 | 2.99 | 1.99 | 5.97 | 23.9 | 1039.6 | 80.55 | 0.0917 |

| 315 | 16 | 315 | 51.3 | 366 | 26 | 7 | 3.93 | 3.05 | 9.16 | 24.9 | 1269.7 | 110.43 | 0.0917 |

| 400 | 7 | 400 | 27.7 | 428 | 45 | 7 | 3.36 | 2.24 | 6.73 | 26.9 | 1320.1 | 100.29 | 0.0722 |

| 400 | 13 | 400 | 51.9 | 452 | 54 | 7 | 3.07 | 3.07 | 9.21 | 27.6 | 1510.3 | 126.67 | 0.0723 |

| 450 | 7 | 450 | 31.1 | 481 | 45 | 7 | 3.57 | 2.38 | 7.14 | 28.5 | 1485.2 | 109.64 | 0.0642 |

| 450 | 13 | 450 | 58.3 | 508 | 54 | 7 | 3.26 | 3.26 | 9.77 | 29.3 | 1699.1 | 142.5 | 0.0643 |

| 500 | 7 | 500 | 34.6 | 535 | 45 | 7 | 3.76 | 2.51 | 7.52 | 30.1 | 1650.2 | 121.83 | 0.0578 |

| 500 | 13 | 500 | 64.8 | 565 | 54 | 7 | 3.43 | 3.43 | 10.3 | 30.9 | 1887.9 | 158.33 | 0.0578 |

| 560 | 7 | 560 | 38.7 | 599 | 45 | 7 | 3.98 | 2.65 | 7.96 | 31.8 | 1848.2 | 136.45 | 0.0516 |

| 560 | 13 | 560 | 70.9 | 631 | 54 | 19 | 3.63 | 2.18 | 10.9 | 32.7 | 2103.4 | 177.56 | 0.0516 |

| 630 | 7 | 630 | 43.6 | 674 | 45 | 7 | 4.22 | 2.81 | 8.44 | 33.8 | 2079.2 | 153.5 | 0.0459 |

| 630 | 13 | 630 | 79.8 | 710 | 54 | 19 | 3.85 | 2.31 | 11.6 | 34.7 | 2366.3 | 197.36 | 0.0459 |

| 710 | 7 | 710 | 49.1 | 759 | 45 | 7 | 4.48 | 2.99 | 8.96 | 35.9 | 2343.2 | 172.99 | 0.0407 |

| 710 | 13 | 710 | 89.9 | 800 | 54 | 19 | 4.09 | 2.45 | 12.3 | 36.8 | 2666.8 | 222.42 | 0.0407 |

| 800 | 4 | 800 | 34.6 | 835 | 72 | 7 | 3.76 | 2.51 | 7.52 | 37.6 | 2480.2 | 169.83 | 0.0361 |

| 800 | 8 | 800 | 66.7 | 867 | 84 | 7 | 3.48 | 3.48 | 10.4 | 38.3 | 2732.7 | 210 | 0.0362 |

| 800 | 13 | 800 | 101 | 901 | 54 | 19 | 4.44 | 2.61 | 13 | 39.1 | 3004.9 | 250.61 | 0.0362 |

| 900 | 4 | 900 | 38.9 | 939 | 72 | 7 | 3.99 | 2.66 | 7.98 | 39.9 | 2790.2 | 191.06 | 0.0321 |

| 900 | 8 | 900 | 75 | 975 | 84 | 7 | 3.69 | 3.69 | 11.1 | 40.6 | 3074.2 | 226.5 | 0.0322 |

| 1000 | 4 | 1000 | 43.2 | 1043 | 72 | 7 | 4.21 | 2.8 | 8.41 | 42.1 | 3100.3 | 212.28 | 0.0289 |

| 1120 | 4 | 1120 | 47.3 | 1167 | 72 | 19 | 4.45 | 1.78 | 8.9 | 44.5 | 3464.9 | 237.84 | 0.0258 |

| 1120 | 8 | 1120 | 91.2 | 1211 | 84 | 19 | 4.12 | 2.47 | 12.4 | 45.3 | 3811.5 | 289.55 | 0.0258 |

| 1250 | 8 | 1250 | 52.8 | 1303 | 72 | 19 | 4.7 | 1.88 | 9.4 | 47 | 3867.1 | 265.44 | 0.0231 |

| 1250 | 4 | 1250 | 102 | 1352 | 84 | 19 | 4.35 | 2.61 | 13.1 | 47.9 | 4253.9 | 323.16 | 0.0232 |

| Nominal Corss-section | Number of Wires | Wire Diameter | Calculated Cross-section | Overall Diameter | D.C. Resistance at 20 | Min. Breaking Load | Conductor Weight | Grease Weight |

| mm2 | mm | mm2 | mm | Ω/km | kg/km | kg/km | ||

| 10 | 7 | 1,35 | 10,0 | 4,05 | 28,631 | 1950 | 27,4 | – |

| 16 | 7 | 1,70 | 15,9 | 5,10 | 18,007 | 3021 | 43,0 | 0,5 |

| 25 | 7 | 2,13 | 24,9 | 6,40 | 11,498 | 4500 | 68,0 | 0,5 |

| 35 | 7 | 2,50 | 34,3 | 7,50 | 0,8347 | 5913 | 94,0 | 0,5 |

| 40 | 7 | 2,70 | 40,0 | 8,09 | 0,7157 | 6800 | 109,4 | – |

| 50 | 7 | 3,00 | 49,5 | 9,00 | 0,5784 | 8198 | 135,0 | 0,5 |

| 63 | 7 | 3,39 | 63,0 | 10,16 | 0,4544 | 10390 | 172,3 | – |

| 70 | 7 | 3,55 | 69,3 | 10,70 | 0,4131 | 11288 | 189,0 | 1,0 |

| 95 | 7 | 4,10 | 92,4 | 12,30 | 0,3114 | 14784 | 252,0 | 1,0 |

| 100 | 19 | 2,59 | 100,0 | 12,94 | 0,2877 | 17000 | 274,9 | – |

| 120 | 19 | 2,80 | 117,0 | 14,00 | 0,2459 | 19890 | 321,0 | 16 |

| 125 | 19 | 2,89 | 125,0 | 14,47 | 0,2301 | 21250 | 343,6 | – |

| 150 | 19 | 3,15 | 148,0 | 15,80 | 0,1944 | 24420 | 406,0 | 20 |

| 160 | 19 | 3,27 | 160,0 | 16,37 | 0,1798 | 26400 | 439,8 | – |

| 185 | 19 | 3,50 | 182,8 | 17,50 | 0,1574 | 29832 | 502,0 | 25 |

| 200 | 19 | 3,66 | 200,0 | 18,30 | 0,1438 | 32000 | 549,7 | – |

| 240 | 19 | 4,00 | 238,7 | 20,00 | 0,1205 | 38192 | 655,0 | 33 |

| 250 | 19 | 4,09 | 250,0 | 20,47 | 0,1150 | 40000 | 687,1 | – |

| 300 | 37 | 3,15 | 288,3 | 22,10 | 0,1000 | 47569 | 794,0 | 54 |

| 315 | 37 | 3,29 | 315,0 | 23,05 | 0,0915 | 51970 | 867,5 | – |

| 350 | 37 | 3,45 | 345,8 | 24,20 | 0,0833 | 57057 | 952,0 | 65 |

| 400 | 37 | 3,66 | 389,2 | 25,60 | 0,0740 | 63420 | 1072,0 | 73 |

| 450 | 37 | 3,90 | 449,1 | 27,30 | 0,0642 | 71856 | 1206,0 | 84 |

| 500 | 37 | 4,15 | 500,4 | 29,10 | 0,0576 | 80000 | 1378,0 | 94 |

| 550 | 61 | 3,37 | 544,0 | 30,30 | 0,0529 | 89760 | 1500,0 | 117 |

| 560 | 37 | 4,39 | 560,0 | 30,73 | 0,0531 | 89600 | 1542,2 | – |

| 600 | 61 | 3,50 | 586,8 | 31,50 | 0,0491 | 95632 | 1618,0 | 126 |

| 630 | 61 | 3,63 | 630,0 | 32,64 | 0,0458 | 100800 | 1738,4 | – |

| 650 | 61 | 3,66 | 641,7 | 32,90 | 0,0450 | 104575 | 1771,0 | 138 |

| 700 | 61 | 3,80 | 691,7 | 34,20 | 0,0417 | 112725 | 1902,0 | 149 |

| 710 | 61 | 3,85 | 710,0 | 34,65 | 0,0406 | 113600 | 1959,2 | – |

| 750 | 61 | 3,95 | 747,4 | 35,60 | 0,0386 | 119584 | 2062,0 | 161 |

| CODE | SECTION | STRANDING | OVERALL DIAMETER | TENSILE S. STEEL HBAR. | RATED STRENGTH | ELECTRICAL RESISTANCE 20ºC | CONDUCTOR WEIGHT | GREASE WEIGHT | |||||||

| mm2 | No. x mm | mm | kN | ohms/km | kg/km | g/m | |||||||||

| Al | Steel | Total | Al | Steel | Core | Total | Al | Steel | Total | Outside layer greased | Outside layer ungreased | ||||

| CANNA 37.7 | 28.27 | 9.42 | 37.69 | 9 x 2.00 | 3 x 2.00 | - | 8.3 | 117.6 | 1.625 | 1.02 | 80 | 155 | 75 | 6 | 2 |

| CANNA 59.7 | 37.7 | 21.99 | 59.69 | 12 x 2.00 | 7 x 2.00 | 6 | 10 | 117.6 | 3.27 | 0.766 | 103 | 276 | 173 | 7 | 3 |

| CANNA 75.5 | 47.71 | 27.83 | 75.54 | 12 x 2.25 | 7 x 2.25 | 6.75 | 11.25 | 117.6 | 4.115 | 0.605 | 128 | 349 | 220 | 10 | 4 |

| CANNA 116.2 | 94.25 | 21.99 | 116.24 | 30 x 2.00 | 7 x 2.00 | 6 | 14 | 117.6 | 4.315 | 0.306 | 258 | 432 | 174 | 13 | 7 |

| CROCUS 116.12 | 94.25 | 21.99 | 116.24 | 30 x 2.00 | 7 x 2.00 | 6 | 14 | 156.8 | 4.93 | 0.306 | 258 | 432 | 174 | 13 | 7 |

| CANNA 147.1 | 119.28 | 27.83 | 147.11 | 30 x 2.25 | 7 x 2.25 | 6.75 | 15.75 | 117.6 | 5.4 | 0.243 | 327 | 547 | 220 | 18 | 10 |

| CROCUS 147.1 | 119.28 | 27.83 | 147.11 | 30 x 2.25 | 7 x 2.25 | 6.75 | 15.75 | 156.8 | 6.18 | 0.243 | 327 | 547 | 220 | 18 | 10 |

| CANNA 181.6 | 147.26 | 34.36 | 181.62 | 30 x 2.50 | 7 x 2.50 | 7.5 | 17.5 | 117.6 | 6.49 | 0.197 | 403 | 675 | 272 | 22 | 12 |

| CROCUS 181.6 | 147.26 | 34.36 | 181.62 | 30 x 2.50 | 7 x 2.50 | 7.5 | 17.5 | 156.8 | 7.42 | 0.197 | 403 | 675 | 272 | 22 | 12 |

| CANNA 228 | 184.72 | 43.1 | 227.82 | 30 x 2.80 | 7 x 2.80 | 8.4 | 19.6 | 117.6 | 8.05 | 0.157 | 506 | 848 | 342 | 26 | 15 |

| CROCUS 228 | 184.72 | 43.1 | 227.82 | 30 x 2.80 | 7 x 2.80 | 8.4 | 19.6 | 156.8 | 9.21 | 0.157 | 506 | 848 | 342 | 26 | 15 |

| CANNA 288 | 233.8 | 54.55 | 288.35 | 30 x 3.15 | 7 x 3.15 | 9.45 | 22.05 | 117.6 | 9.85 | 0.124 | 642 | 1074 | 432 | 33 | 18 |

| CROCUS 288 | 233.8 | 54.55 | 288.35 | 30 x 3.15 | 7 x 3.15 | 9.45 | 22.05 | 156.8 | 11.38 | 0.124 | 642 | 1074 | 432 | 33 | 18 |

| CROCUS 297 | 221.67 | 75.54 | 297.21 | 36 x 2.80 | 19 x 2.25 | 11.25 | 22.45 | 156.8 | 17.72 | 0.1305 | 594 | 624 | 1218 | 35 | 20 |

| CROCUS 412 | 325.72 | 85.95 | 411.67 | 32 x 3.60 | 19 x 2.40 | 12 | 26.4 | 156.8 | 17.33 | 0.0898 | 676 | 917 | 1593 | 50 | 25 |

| CROCUS 612 | 507.83 | 104.7 | 611.76 | 66 x 3.13 | 19 x 2.65 | 13.25 | 32.2 | 156.8 | 23.15 | 0.0566 | 824 | 1417 | 2241 | 70 | 40 |

| CROCUS 865 | 717.33 | 148.06 | 865.39 | 66 x 3.72 | 19 x 3.15 | 15.75 | 38.1 | 156.8 | 31.9 | 0.0405 | 1164 | 2010 | 3174 | 100 | 55 |

| CROCUS 1185 | 956.666 | 227.82 | 1184.48 | 54 x 2.8 | 37 x 2.80 | 19.7 | 44.7 | 156.8 | 48.05 | 0.0303 | 1796 | 2682 | 4478 | 140 | 100 |

| Nominal Sectional Area | Sectional Area | Stranding | Overall Diameter | Weight | Breakign Load | Electrical Resistance @20o | |||

| AL | Steel | Total | AL | Steel | |||||

| mm^2 | mm^2 | mm^2 | mm^2 | No.×mm | No.×mm | mm | Kg/Km | KN | Ω/Km |

| 25 | 24.9 | 4.2 | 29.1 | 6/2.30 | 1/2.30 | 6.9 | 101 | 8.89 | 1.15 |

| 32 | 31.9 | 5.3 | 37.2 | 6/2.60 | 1/2.60 | 7.8 | 129 | 11.17 | 0.899 |

| 58 | 57.7 | 9.6 | 67.3 | 6/3.50 | 1/3.50 | 10.5 | 233 | 19.4 | 0.497 |

| 95 | 95.4 | 15.9 | 111.3 | 6/4.50 | 1/4.50 | 13.5 | 385 | 31.16 | 0.301 |

| 120 | 124.7 | 29.1 | 153.8 | 30/2.3 | 7/2.3 | 16.1 | 574 | 54.29 | 0.233 |

| 160 | 159.3 | 37.2 | 196.5 | 30/2.6 | 7/2.6 | 18.2 | 733 | 68.4 | 0.182 |

| 200 | 198.2 | 46.2 | 244.4 | 30/2.9 | 7/2.9 | 20.3 | 912 | 84.67 | 0.147 |

| 240 | 241.2 | 59.3 | 300.5 | 30/3.2 | 7/3.2 | 22.4 | 1110 | 100.06 | 0.12 |

| 330 | 326.8 | 52.8 | 379.6 | 26/4.0 | 7/3.1 | 25.3 | 1320 | 107.31 | 0.0888 |

| 410 | 413.4 | 67.3 | 480.7 | 26/4.5 | 7/3.5 | 28.5 | 1673 | 136.32 | 0.0702 |

| 520 | 519.5 | 67.3 | 586.8 | 54/3.5 | 7/3.5 | 31.2 | 1969 | 152.88 | 0.0559 |

| 610 | 612.4 | 79.4 | 691.8 | 54/3.8 | 7/3.8 | 34.2 | 2320 | 179.83 | 0.0474 |

| 810 | 814.5 | 56.3 | 870.8 | 45/3.8 | 7/3.2 | 38.4 | 2700 | 181.1 | 0.0356 |