Description

Exothermic Welding is a simple, effective, quality welding method, that welds the parts to the desired size and type in a graphite mold cave with overheated melting. Currently, exothermic welding replaced mechanical connection.

Exothermic Welding Mold: The mold is made of a quality graphite body to obtain the perfect seal and lasting performance. The life of our mold can be 80-100 joints, which is more lasting than other competitor’s.

Exothermic welding powder: We mix the powder to comply with your conductor’s material and size with a reasonable ratio, so the joint is more strong and more lasting.

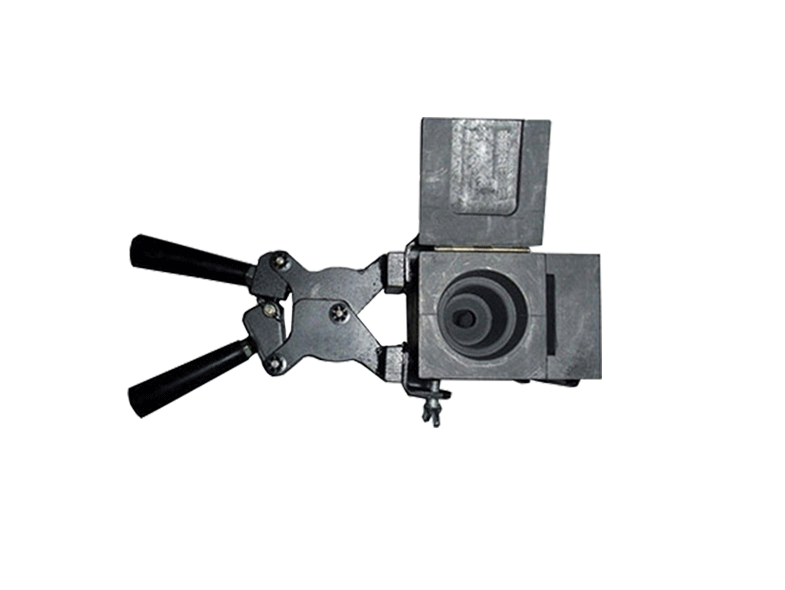

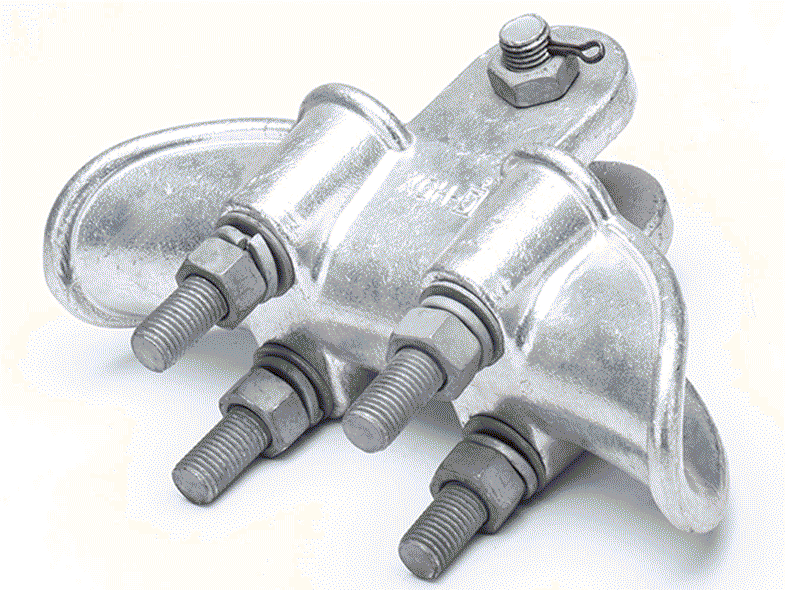

Exothermic Welding Clamp: The clamp makes sure the mold is closed during welding. We can provide the scale of the mold, or we can make the clamps according to the customer's demand.

Welding toolbox: We offer the full sets of tools to meet your demand, including an ignition gun, brush, screwdriver, and glove. It is a package box to meet your whole demand. Product Parameter

Product Parameter

The Size OF Exothermic Welding Powder

Product Advantages

(1). Good current loading ability: The welding point current loading ability is the same as that of the conductor;

(2). Good mechanical performance: The connection is a molecular connection. It is a permanent connection, no loss or corrosion results in high resistance;

(3). Stable dash current resistance: The test shows that in the surge of a big current in a short time, and the conductor melts earlier than the connection point, no damage by the surge current.

(4). Good corrosion resistance: The welding joint is covered by copper and more strong than copper, it provides good resistance to corrosion.

(5). Simple and safe connection: Neither outside power nor facility is required. It takes very little time to finish one welding both indoors and outdoors.

(6). Free control of the reaction temperature: Different welding powder is provided according to the metal features, so the welding powder can be very solid.

Welding Property

Welding Fluxe is also called aluminum heat welding powder. Use proper exothermic fluxes to make the connection joints more solid and extend the user's life.

Main content and ratio of welding powder:

Properties of joint:

Resistance of joint:

Strength of joint:

Exothermic Welding is a simple, effective, quality welding method, that welds the parts to the desired size and type in a graphite mold cave with overheated melting. Currently, exothermic welding replaced mechanical connection.

Exothermic Welding Mold: The mold is made of a quality graphite body to obtain the perfect seal and lasting performance. The life of our mold can be 80-100 joints, which is more lasting than other competitor’s.

Exothermic welding powder: We mix the powder to comply with your conductor’s material and size with a reasonable ratio, so the joint is more strong and more lasting.

Exothermic Welding Clamp: The clamp makes sure the mold is closed during welding. We can provide the scale of the mold, or we can make the clamps according to the customer's demand.

Welding toolbox: We offer the full sets of tools to meet your demand, including an ignition gun, brush, screwdriver, and glove. It is a package box to meet your whole demand.

| Material of Exothermic Welding Mold | Graphite |

| Material of Exothermic Welding Powder | Cu, Al, Fe |

| Material of Exothermic Welding Clamp | Carbon steel |

| Size | According to customer's requirement |

| Characters | Easy to use and safe |

The Size OF Exothermic Welding Powder

| Product No | Weight |

| EWM -C90 | 90g |

| EWM -C115 | 115g |

| EWM -C150 | 150g |

| EWM -C200 | 200g |

| EWM -C250 | 250g |

| EWM –C300 | 300g |

Product Advantages

(1). Good current loading ability: The welding point current loading ability is the same as that of the conductor;

(2). Good mechanical performance: The connection is a molecular connection. It is a permanent connection, no loss or corrosion results in high resistance;

(3). Stable dash current resistance: The test shows that in the surge of a big current in a short time, and the conductor melts earlier than the connection point, no damage by the surge current.

(4). Good corrosion resistance: The welding joint is covered by copper and more strong than copper, it provides good resistance to corrosion.

(5). Simple and safe connection: Neither outside power nor facility is required. It takes very little time to finish one welding both indoors and outdoors.

(6). Free control of the reaction temperature: Different welding powder is provided according to the metal features, so the welding powder can be very solid.

Welding Property

Welding Fluxe is also called aluminum heat welding powder. Use proper exothermic fluxes to make the connection joints more solid and extend the user's life.

Main content and ratio of welding powder:

| Element | Ratio Wt/% |

| Cu | ≥76.0 |

| Al | ≤2.0 |

| Fe | ≤10.0 |

Properties of joint:

| Properties | Technology index |

| Conductivity | Resistance of the conductor (Including joint) should be less than that of same length base metal |

| Strength | Joint strength should not be less than 95% of the low limit of raw material’s strength (CCS material is regarded as pure copper ) |

| High melting point | ≥1 083 ℃ |

| Surface | No air hole, residue and crack section |

| n quality | e max size any whither should be higher than 1/3 of the thickness(or 1/4 of diameter) but should be less than 3mm |

Resistance of joint:

| Resistance /μΩ | Test location |

| 113 | Distance between tested location:15 cm |

| Strength Rm/MPa | Remark |

| 340 | No crack and base metal offshore instruction: The flame point of powder is very high, so pyrophoric powder is a must to ignite, the store condition should be dry, cool, with no shine, and no humidity. If the packing is damaged, please don’t use it. |