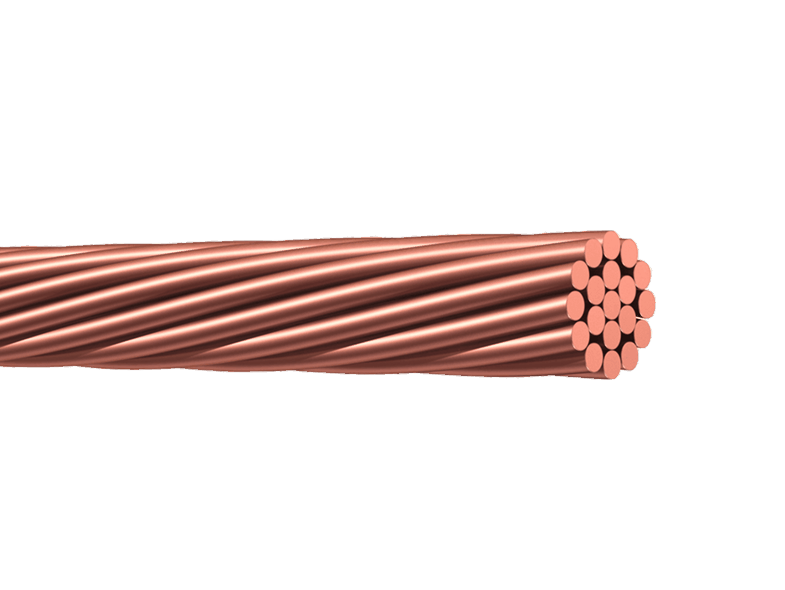

Application

Stranded Class 2 bare copper wire to BS EN 60228 / IEC 60228 cables are non insulated and non sheathed soft drawn copper to BS6360/81. Stranded bare soft or annealed copper conductors are recommended for use as neutrals, in circuit ground connections as well as machinery and equipment grounding systems. Soft copper may be used for transformer drop leads or other non-tension hook-up jumpers.Solid and stranded (classes AA and A) bare copper are suitable for overhead transmission and distribution applications. Stranded conductor of greater flexibility (classes B and C) are suitable for uninsulated hook up, jumpers, and grounds in electrical construction. Soft Drawn copper is unilay construction.

Standard

• BS 6360 and BS EN 60228 / IEC 60228• ASTM B-1 Hard-Drawn Copper Wire.

• ASTM B-2 Medium-Hard Copper Wire.

• ASTM B-3 Soft or Annealed Copper Wire.

• ASTM B-787 19 Wire Combination Unilay-Stranded Soft copper wire.

• ASTM B-8 Concentric-Lay-Stranded Hard, Medium-Hard or Soft Copper Conductor.

Features And Benefits

Stranded bare soft or annealed copper conductors are suitable for direct burial and do not suffer from the inherent corrosion problems that an aluminum conductor would. Copper is almost twice as conductive as aluminum. Copper is easier than aluminum to terminate and join at splices and joints.

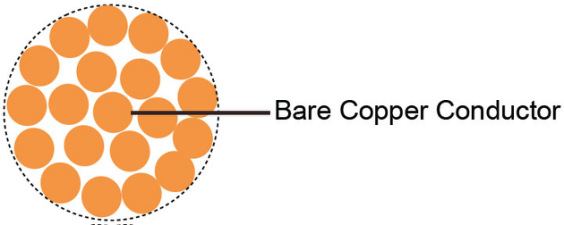

Construction

Bare copper, solid or stranded. Available in tempers hard, medium-hard, or soft. Stranded conductors are concentrically stranded in hard and medium-hard tempers and are Combination Unilay stranded in the soft-drawn temper.Construction Parameters

| Part No. | Cross Section | No./Nominal Diameter of Strands | Conductor Nominal Diameter | Approx. Weight | Max. DC Resistance at 20℃ | |||||||||||

| mm^2 | No./mm | mm | kg/km | Ω/km | ||||||||||||

| CCL-BC-R 50 | 50 mm^2 | 19/1.78 | 8.9 | 430 | 0.387 | |||||||||||

| CCL-BC-R 70 | 70 mm^2 | 19/2.14 | 10.7 | 625 | 0.268 | |||||||||||

| CCL-BC-R 95 | 95 mm^2 | 19/2.52 | 12.6 | 866 | 0.193 | |||||||||||

| CCL-BC-R 120 | 120 mm^2 | 37/2.03 | 14.25 | 1090 | 0.153 | |||||||||||

| CCL-BC-R 185 | 185 mm^2 | 37/2.52 | 17.64 | 1680 | 0.099 | |||||||||||

| CCL-BC-R 240 | 240 mm^2 | 61/2.25 | 20.3 | 2220 | 0.075 | |||||||||||

| CCL-BC-R 300 | 300 mm^2 | 61/2.52 | 22.68 | 2780 | 0.06 | |||||||||||

| Size (AWG) | Weight (lbs/1000 ft) | Diameter (mils) | Circular Mil Area (mils) | Hard Drawn | Medium-Hard Drawn | Soft-Drawn (Annealed) | Allowable Ampacity+ | |||||||||

| Rated Strength> (lbs) | DC | Rated Strength (lbs) | DC | Rated Strength (lbs) | DC | |||||||||||

| Resistance (ohms/1000 ft) | Resistance (ohms/1000 ft) | Resistance (ohms/1000 ft) | ||||||||||||||

| @20°C | @20°C | @20°C | ||||||||||||||

| SOLID | ||||||||||||||||

| 14 | 12.4 | 64.1 | 4110 | 213.5 | 2.626 | 166.6 | 2.613 | 124.2 | 2.525 | -- | ||||||

| 13 | 15.7 | 72 | 5180 | 268 | 2.083 | 208.8 | 2.072 | 156.6 | 2.003 | -- | ||||||

| 12 | 19.8 | 80.8 | 6530 | 336.9 | 1.652 | 261.2 | 1.643 | 197.5 | 1.588 | -- | ||||||

| 11 | 24.9 | 90.7 | 8230 | 422.9 | 1.31 | 327.6 | 1.303 | 249 | 1.26 | -- | ||||||

| 10 | 31.4 | 101.9 | 10380 | 529.2 | 1.039 | 410.4 | 1.033 | 314 | 0.999 | -- | ||||||

| 9 | 39.6 | 114.4 | 13090 | 661.2 | 0.824 | 514.2 | 0.82 | 380.5 | 0.792 | -- | ||||||

| 8 | 50 | 128.5 | 16510 | 826 | 0.653 | 643.9 | 0.65 | 479.8 | 0.628 | 95 | ||||||

| 7 | 63 | 144.3 | 20820 | 1030 | 0.518 | 806.6 | 0.515 | 605 | 0.498 | 105 | ||||||

| 6 | 79.4 | 162 | 26240 | 1280 | 0.411 | 1010 | 0.409 | 762.9 | 0.395 | 125 | ||||||

| 5 | 100.2 | 181.9 | 33090 | 1591 | 0.326 | 1265 | 0.324 | 961.9 | 0.313 | 145 | ||||||

| 4 | 126.3 | 204.3 | 41740 | 1970 | 0.258 | 1584 | 0.257 | 1213 | 0.249 | 170 | ||||||

| 3 | 159.3 | 229.4 | 52620 | 2439 | 0.205 | 1984 | 0.204 | 1530 | 0.197 | 195 | ||||||

| 2 | 200.9 | 257.6 | 66360 | 3003 | 0.163 | 2450 | 0.162 | 1929 | 0.156 | 225 | ||||||

| 1 | 253.3 | 289.3 | 83690 | 3688 | 0.129 | 3024 | 0.128 | 2432 | 0.124 | 260 | ||||||

| +Ampacity based on 75°C conductor temperature; 25°C ambient temperature; 2 ft./sec. wind in sun. | ||||||||||||||||

| Size (AWG) | Stranding | Stranding Class | Weight (lbs/1000 ft) | Diameter (mils) | Hard Drawn | Medium-Hard Drawn | Soft-Drawn (Annealed) | Allowable Ampacity+ | ||||

| Individual Wires | Complete Conductor | Rated Strength (lbs) | DC | Rated Strength (lbs) | DC | Rated Strength (lbs) | DC | |||||

| Resistance (ohms/1000 ft) | Resistance (ohms/1000 ft) | Resistance (ohms/1000 ft) | ||||||||||

| @20°C | @20°C | @20°C | ||||||||||

| STRANDED | ||||||||||||

| 8 | 7 | B | 51 | 49 | 146 | 777 | 0.6663 | 610 | 0.6629 | 499 | 0.6408 | 95 |

| 6 | 7 | B | 81 | 61 | 184 | 1228 | 0.4191 | 959 | 0.4169 | 794 | 0.403 | 130 |

| 4 | 7 | A, B | 128.9 | 77 | 232 | 1938 | 0.2636 | 1505 | 0.2622 | 1320 | 0.2534 | 170 |

| 3 | 7 | A, B | 162.5 | 87 | 260 | 2433 | 0.209 | 1885 | 0.2079 | 1670 | 0.201 | 200 |

| 2 | 7 | A, B | 204.9 | 97 | 292 | 3050 | 0.166 | 2360 | 0.165 | 2110 | 0.1578 | 230 |

| 1 | 7 | A | 258.4 | 109 | 328 | 3801 | 0.1316 | 2955 | 0.1309 | 2552 | 0.1252 | 265 |

| 1/0 | 7 | A, AA | 326.1 | 123 | 368 | 4752 | 0.1042 | 3705 | 0.1037 | 3221 | 0.1002 | 310 |

| 2/0 | 7 | A, AA | 410.9 | 138 | 414 | 5926 | 0.08267 | 4640 | 0.08224 | 4062 | 0.07949 | 355 |

| 2/0 | 19 | B | 410.9 | 84 | 418 | 6690 | 0.08267 | 4765 | 0.08224 | 4024 | 0.07949 | 355 |

| 3/0 | 7 | A, AA | 518.1 | 155 | 464 | 7366 | 0.06556 | 5812 | 0.06522 | 5118 | 0.06304 | 410 |

| 4/0 | 7 | A, AA | 653.3 | 174 | 522 | 9154 | 0.05199 | 7278 | 0.05172 | 6459 | 0.04999 | 480 |

| 4/0 | 19 | B | 653.3 | 106 | 528 | 9617 | 0.05199 | 7479 | 0.05172 | 6453 | 0.04999 | 480 |

| 250 | 19 | A | 771.9 | 115 | 574 | 11360 | 0.044 | 8836 | 0.04378 | 7627 | 0.04231 | 530 |

| 250 | 37 | B | 771.9 | 82 | 575 | 11600 | 0.044 | 8952 | 0.04378 | 7940 | 0.04231 | 530 |

| 300 | 19 | A | 926.2 | 126 | 628 | 13510 | 0.03667 | 10530 | 0.03648 | 9160 | 0.03526 | 590 |

| 350 | 19 | A | 1080.6 | 136 | 679 | 15590 | 0.03143 | 12200 | 0.03127 | 10680 | 0.03022 | 650 |

| 500 | 37 | A, B | 1543.8 | 116 | 814 | 22510 | 0.022 | 17550 | 0.02189 | 15240 | 0.02116 | 810 |

| 600 | 37 | A, AA | 1852.5 | 127 | 891 | 27020 | 0.01834 | 21060 | 0.01825 | 18300 | 0.01763 | 910 |

| 750 | 61 | A, B | 2315.6 | 111 | 998 | 34090 | 0.01467 | 26510 | 0.01459 | 22890 | 0.0141 | 1040 |

| 1000 | 61 | A, B | 3087.5 | 128 | 1152 | 45030 | 0.011 | 35100 | 0.01094 | 30500 | 0.01058 | 1240 |

| +Ampacity based on 75°C conductor temperature; 25°C ambient temperature; 2 ft./sec. wind in sun. | ||||||||||||