Product Description

Earth inspection pit is a prefabricated object made of plastic or concrete to test the performance of grounding devices. This product can be widely used in auxiliary engineering of grounding facilities in various fields such as work grounding, protective grounding, anti-interference grounding, lightning protection grounding, and anti-static, providing great convenience for real-time monitoring of grounding efficiency and inspection of grounding effect.

Its performance characteristics are:

1. Using inorganic non-metallic materials with excellent mechanical properties as the lining medium for observation wells, its mechanical properties are far superior to similar products, and it can maintain long-term stability without embrittlement or fracture phenomena.

2. By adopting seamless waterproof measures and high hydrophobic materials for observation and logging, the grounding dew point metal is efficiently protected, greatly delaying the corrosion of the dew point metal. The waterproof and corrosion resistance performance of the well body is excellent.

3. The material of the well body is green and environmentally friendly, corrosion-resistant, non-toxic, and easy to install.

4. The product can withstand a low temperature of -40 ℃, and is also suitable for high and cold areas in the north.

Practice Of Earth Inspection Pit

1. Determine the location of the earth inspection pit: the location of the earth inspection pit shall be set as required, usually near the key parts of the Earthing system, such as the transformer, distribution room, main distribution box and other grounding points.

2. Excavation of inspection pits: According to the design requirements, excavate inspection pits that meet the specifications. The bottom of the well should be 30-50cm lower than the surrounding ground, and the wellhead should be 20-30cm higher than the ground. The well wall should be flat and vertical, and the structure and stability of the well should be ensured

3. Installation of wellbore: According to the design requirements, select a wellbore that meets the requirements for installation. The wellbore should have good anti-corrosion, pressure resistance, and sealing performance. The height of the wellbore should meet the design requirements, and attention should be paid to the embedding depth of the wellbore, usually 10-20cm below the wellbore wall.

4. Installation of manhole cover: According to the design requirements, select a manhole cover that meets the requirements for installation. The manhole cover should have good anti-corrosion, pressure resistance, and anti-skid performance. The manhole cover should be well sealed with the wellbore to ensure safety and hygiene inside the well.

5.Connection of Earthing system: the conductor of the Earthing system shall be connected to the grounding inspection well by copper bar or copper wire. The connection line shall meet the design requirements and ensure good electrical contact at the connection

6. Test the grounding resistance: after installing the grounding inspection well, the grounding resistance test is required to check whether the grounding performance of the Earthing system meets the requirements. During the testing process, attention should be paid to

Safety measures should be taken and testing instruments that meet the requirements should be used for testing.

7. Regular maintenance: As an important part of the Earthing system, the earthing inspection well needs regular maintenance and inspection to ensure its stability and reliability. During maintenance, safety measures should be taken and operations such as cleaning, repairing, and replacing should be carried out as needed.

Application

This product is widely used in lightning protection grounding, working grounding, and anti-static grounding of facilities such as power, railways, buildings, mines, chemicals, national defense, various factories, warehouses, etc., especially in places that require real-time monitoring of grounding effectiveness.

Earth inspection pit is a prefabricated object made of plastic or concrete to test the performance of grounding devices. This product can be widely used in auxiliary engineering of grounding facilities in various fields such as work grounding, protective grounding, anti-interference grounding, lightning protection grounding, and anti-static, providing great convenience for real-time monitoring of grounding efficiency and inspection of grounding effect.

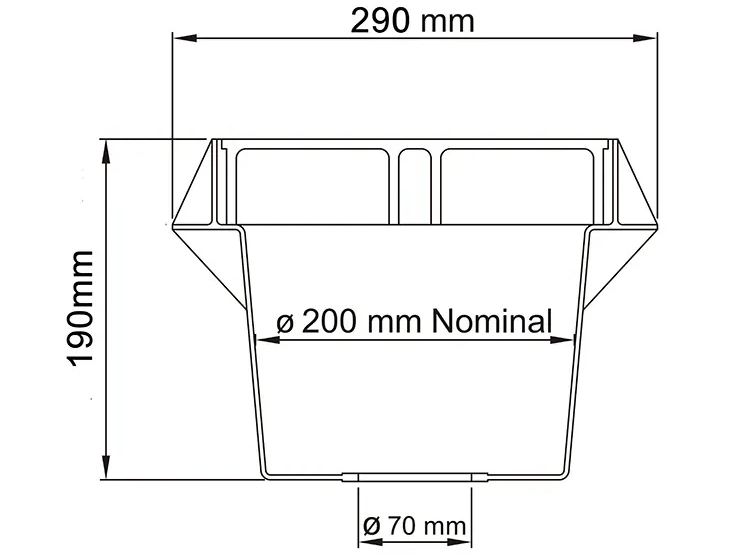

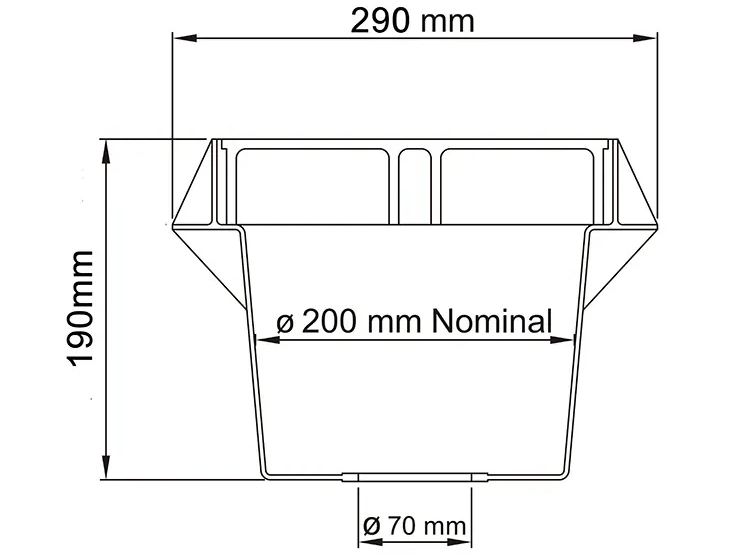

| Product name | Earth Inspection Pit |

| Material | PVC |

| Application | Grounding and Lightning Protection Devices |

| Service life | More than 50 years |

| Size | 280*280*180mm |

| Service mode | OEM & ODM |

| Certificate | ISO9001:2008 |

Its performance characteristics are:

1. Using inorganic non-metallic materials with excellent mechanical properties as the lining medium for observation wells, its mechanical properties are far superior to similar products, and it can maintain long-term stability without embrittlement or fracture phenomena.

2. By adopting seamless waterproof measures and high hydrophobic materials for observation and logging, the grounding dew point metal is efficiently protected, greatly delaying the corrosion of the dew point metal. The waterproof and corrosion resistance performance of the well body is excellent.

3. The material of the well body is green and environmentally friendly, corrosion-resistant, non-toxic, and easy to install.

4. The product can withstand a low temperature of -40 ℃, and is also suitable for high and cold areas in the north.

Practice Of Earth Inspection Pit

1. Determine the location of the earth inspection pit: the location of the earth inspection pit shall be set as required, usually near the key parts of the Earthing system, such as the transformer, distribution room, main distribution box and other grounding points.

2. Excavation of inspection pits: According to the design requirements, excavate inspection pits that meet the specifications. The bottom of the well should be 30-50cm lower than the surrounding ground, and the wellhead should be 20-30cm higher than the ground. The well wall should be flat and vertical, and the structure and stability of the well should be ensured

3. Installation of wellbore: According to the design requirements, select a wellbore that meets the requirements for installation. The wellbore should have good anti-corrosion, pressure resistance, and sealing performance. The height of the wellbore should meet the design requirements, and attention should be paid to the embedding depth of the wellbore, usually 10-20cm below the wellbore wall.

4. Installation of manhole cover: According to the design requirements, select a manhole cover that meets the requirements for installation. The manhole cover should have good anti-corrosion, pressure resistance, and anti-skid performance. The manhole cover should be well sealed with the wellbore to ensure safety and hygiene inside the well.

5.Connection of Earthing system: the conductor of the Earthing system shall be connected to the grounding inspection well by copper bar or copper wire. The connection line shall meet the design requirements and ensure good electrical contact at the connection

6. Test the grounding resistance: after installing the grounding inspection well, the grounding resistance test is required to check whether the grounding performance of the Earthing system meets the requirements. During the testing process, attention should be paid to

Safety measures should be taken and testing instruments that meet the requirements should be used for testing.

7. Regular maintenance: As an important part of the Earthing system, the earthing inspection well needs regular maintenance and inspection to ensure its stability and reliability. During maintenance, safety measures should be taken and operations such as cleaning, repairing, and replacing should be carried out as needed.

Application

This product is widely used in lightning protection grounding, working grounding, and anti-static grounding of facilities such as power, railways, buildings, mines, chemicals, national defense, various factories, warehouses, etc., especially in places that require real-time monitoring of grounding effectiveness.