Application

Composite Insulated FRP Lightning Rod Introduction

The composite insulated FRP lightning rod, also known as (anti-side flash composite insulated lightning arrester), is a new type of lightning protection equipment, mainly composed of a FRP tube made of high-strength composite insulating materials and a metal lightning arrester. The top is a stainless steel metal lightning arrester, which leads the lightning current into the ground through the insulated down conductor, thereby protecting buildings, facilities and personnel from the harm of lightning.

Features of composite insulated FRP lightning rods

1. FRP lightning rods are light, strong, corrosion-resistant, anti-aging, and UV-resistant

2. FRP lightning rods can maintain long-term stable operation even in harsh environments

3. FRP lightning rods have good insulation properties and can maintain stable performance in the temperature range of -40℃ to 80℃

Application areas of composite insulated FRP lightning rods

FRP lightning rods are widely used in many fields, such as building lightning protection, communication base stations, meteorological observation stations, radar stations, petroleum and chemical facilities, etc. Especially in high-rise buildings, military bases, aerospace and other fields, FRP lightning rods can provide reliable lightning protection without affecting the normal operation of other electronic equipment.

Composite insulated fiberglass lightning rod installation

I. Preparation before installation

1. Site selection planning: ensure coverage of the protected object and surrounding areas

2. Site assessment: topography, building layout, surrounding environment

3. Construction plan: both parties communicate the plan in advance and determine the final construction plan

4. Tools and equipment: crane, wrench, screwdriver, etc.

II. Installation steps

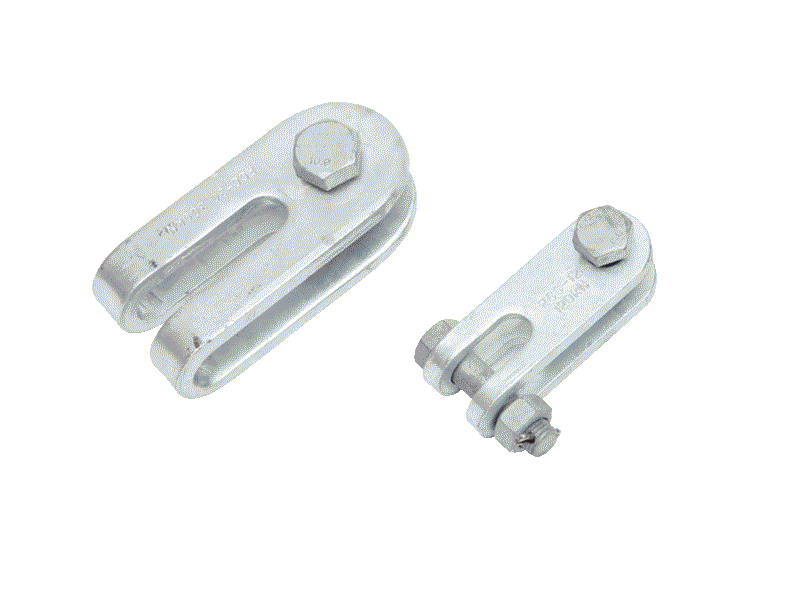

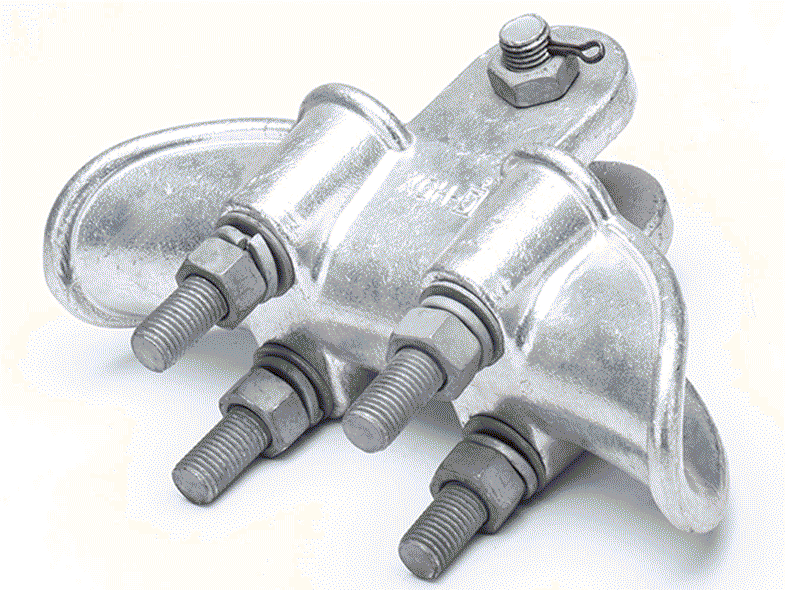

1. Fixed bracket installation: use expansion bolts or welding to fix it on the building

2. Lightning rod main body installation: place it on the bracket and adjust it vertically to the ground

2. Installation steps

1. Fixed bracket installation: Use expansion bolts or welding to fix it on the building

2. Lightning rod main body installation: Place it on the bracket and adjust it vertically to the ground

3. Wiring nose connection: Bolt and weld the lower end of the lightning arrester at one end of the copper wire

4. Modular assembly: Use screws to fix the lightning rod, rod body and base

3. Installation specifications and standards

1. Correct installation method and location are crucial

2. Strictly follow the installation specification requirements

IV. Post-installation maintenance

1. Regular inspection and maintenance: Ensure the lightning rod performs at its best

Composite Insulated FRP Lightning Rod Introduction

The composite insulated FRP lightning rod, also known as (anti-side flash composite insulated lightning arrester), is a new type of lightning protection equipment, mainly composed of a FRP tube made of high-strength composite insulating materials and a metal lightning arrester. The top is a stainless steel metal lightning arrester, which leads the lightning current into the ground through the insulated down conductor, thereby protecting buildings, facilities and personnel from the harm of lightning.

Features of composite insulated FRP lightning rods

1. FRP lightning rods are light, strong, corrosion-resistant, anti-aging, and UV-resistant

2. FRP lightning rods can maintain long-term stable operation even in harsh environments

3. FRP lightning rods have good insulation properties and can maintain stable performance in the temperature range of -40℃ to 80℃

Application areas of composite insulated FRP lightning rods

FRP lightning rods are widely used in many fields, such as building lightning protection, communication base stations, meteorological observation stations, radar stations, petroleum and chemical facilities, etc. Especially in high-rise buildings, military bases, aerospace and other fields, FRP lightning rods can provide reliable lightning protection without affecting the normal operation of other electronic equipment.

Composite insulated fiberglass lightning rod installation

I. Preparation before installation

1. Site selection planning: ensure coverage of the protected object and surrounding areas

2. Site assessment: topography, building layout, surrounding environment

3. Construction plan: both parties communicate the plan in advance and determine the final construction plan

4. Tools and equipment: crane, wrench, screwdriver, etc.

II. Installation steps

1. Fixed bracket installation: use expansion bolts or welding to fix it on the building

2. Lightning rod main body installation: place it on the bracket and adjust it vertically to the ground

2. Installation steps

1. Fixed bracket installation: Use expansion bolts or welding to fix it on the building

2. Lightning rod main body installation: Place it on the bracket and adjust it vertically to the ground

3. Wiring nose connection: Bolt and weld the lower end of the lightning arrester at one end of the copper wire

4. Modular assembly: Use screws to fix the lightning rod, rod body and base

3. Installation specifications and standards

1. Correct installation method and location are crucial

2. Strictly follow the installation specification requirements

IV. Post-installation maintenance

1. Regular inspection and maintenance: Ensure the lightning rod performs at its best