Application

Titanium alloy lightning rods are suitable for direct lightning protection of various buildings, structures, communication base stations, meteorological stations, radar stations, LPG stations, oil derricks, ships, lighthouses, etc. Titanium has high chemical activity and produces strong chemical reactions with 0, N, H, CO, CO2, water vapor, ammonia, etc. in the atmosphere. When the carbon content is greater than 0.2%, a hard TC will be formed in the titanium alloy; when the temperature is high, it will also form a TN hard surface layer with N; above 600°C, titanium absorbs oxygen to form a hardened layer with high hardness; when the hydrogen content rises, a brittle layer will also be formed. The depth of the hard and brittle surface layer produced by absorbing gas can reach 0.1~0.15 mm, and the degree of hardening is 20%~30%. Titanium also has a high chemical affinity and is prone to adhesion to the friction surface.

WXZ-03A titanium alloy lightning rod product materials

1. OCr23Ni28Mo3Cu3Ti

2. 1Cr18Ni12Mo2Ti

3. 304L stainless steel

4. 304L+TA+JLT (high performance material)

WXZ-03A titanium alloy lightning rod product features

1. High strength. The density of titanium alloy is generally around 4.51g/cubic centimeter, which is only 60% of steel. The density of pure titanium is close to that of ordinary steel. Some high-strength titanium alloys exceed the strength of many alloy structural steels. Therefore, the specific strength (strength/density) of titanium alloy is much greater than that of other metal structural materials, and parts with high unit strength, good rigidity and light weight can be produced. Aircraft engine components, skeletons, skins, fasteners and landing gear all use titanium alloys.

2. High thermal strength. The operating temperature is several hundred degrees higher than that of aluminum alloy. It can still maintain the required strength at medium temperature and can work for a long time at 450~500℃. These two types of titanium alloys still have high specific strength in the range of 150℃~500℃, while the specific strength of aluminum alloy decreases significantly at 150℃. The working temperature of titanium alloy can reach 500℃, while that of aluminum alloy is below 200℃. It is more practical to install titanium alloy lightning rods in chimneys or high-temperature areas.

3. Good corrosion resistance. Titanium alloy works in humid atmosphere and seawater medium, and its corrosion resistance is much better than that of stainless steel; it has strong resistance to pitting, acid corrosion and stress corrosion: it has excellent corrosion resistance to alkali, chloride, chlorine organic substances, nitric acid, sulfuric acid, etc. Therefore, YBZ lightning rods are suitable for chimneys or special environments.

4. Good low-temperature performance. Titanium alloy can still maintain its mechanical properties at low and ultra-low temperatures. Titanium alloys with good low-temperature performance and extremely low interstitial elements, such as TA7, can still maintain a certain plasticity at -253℃. Therefore, titanium alloy is also an important low-temperature structural material.

5. Longer life. WX lightning rod has the above advantages and has a longer life than ordinary lightning rods.

6. Simple installation. The installation is fixed according to the instructions or drawings. The special design is simple to install. The grounding resistance should comply with GB50057-2010 Building Lightning Protection Specifications and be less than 10 ohms.

Parameters

Titanium alloy lightning rods are suitable for direct lightning protection of various buildings, structures, communication base stations, meteorological stations, radar stations, LPG stations, oil derricks, ships, lighthouses, etc. Titanium has high chemical activity and produces strong chemical reactions with 0, N, H, CO, CO2, water vapor, ammonia, etc. in the atmosphere. When the carbon content is greater than 0.2%, a hard TC will be formed in the titanium alloy; when the temperature is high, it will also form a TN hard surface layer with N; above 600°C, titanium absorbs oxygen to form a hardened layer with high hardness; when the hydrogen content rises, a brittle layer will also be formed. The depth of the hard and brittle surface layer produced by absorbing gas can reach 0.1~0.15 mm, and the degree of hardening is 20%~30%. Titanium also has a high chemical affinity and is prone to adhesion to the friction surface.

WXZ-03A titanium alloy lightning rod product materials

1. OCr23Ni28Mo3Cu3Ti

2. 1Cr18Ni12Mo2Ti

3. 304L stainless steel

4. 304L+TA+JLT (high performance material)

WXZ-03A titanium alloy lightning rod product features

1. High strength. The density of titanium alloy is generally around 4.51g/cubic centimeter, which is only 60% of steel. The density of pure titanium is close to that of ordinary steel. Some high-strength titanium alloys exceed the strength of many alloy structural steels. Therefore, the specific strength (strength/density) of titanium alloy is much greater than that of other metal structural materials, and parts with high unit strength, good rigidity and light weight can be produced. Aircraft engine components, skeletons, skins, fasteners and landing gear all use titanium alloys.

2. High thermal strength. The operating temperature is several hundred degrees higher than that of aluminum alloy. It can still maintain the required strength at medium temperature and can work for a long time at 450~500℃. These two types of titanium alloys still have high specific strength in the range of 150℃~500℃, while the specific strength of aluminum alloy decreases significantly at 150℃. The working temperature of titanium alloy can reach 500℃, while that of aluminum alloy is below 200℃. It is more practical to install titanium alloy lightning rods in chimneys or high-temperature areas.

3. Good corrosion resistance. Titanium alloy works in humid atmosphere and seawater medium, and its corrosion resistance is much better than that of stainless steel; it has strong resistance to pitting, acid corrosion and stress corrosion: it has excellent corrosion resistance to alkali, chloride, chlorine organic substances, nitric acid, sulfuric acid, etc. Therefore, YBZ lightning rods are suitable for chimneys or special environments.

4. Good low-temperature performance. Titanium alloy can still maintain its mechanical properties at low and ultra-low temperatures. Titanium alloys with good low-temperature performance and extremely low interstitial elements, such as TA7, can still maintain a certain plasticity at -253℃. Therefore, titanium alloy is also an important low-temperature structural material.

5. Longer life. WX lightning rod has the above advantages and has a longer life than ordinary lightning rods.

6. Simple installation. The installation is fixed according to the instructions or drawings. The special design is simple to install. The grounding resistance should comply with GB50057-2010 Building Lightning Protection Specifications and be less than 10 ohms.

Parameters

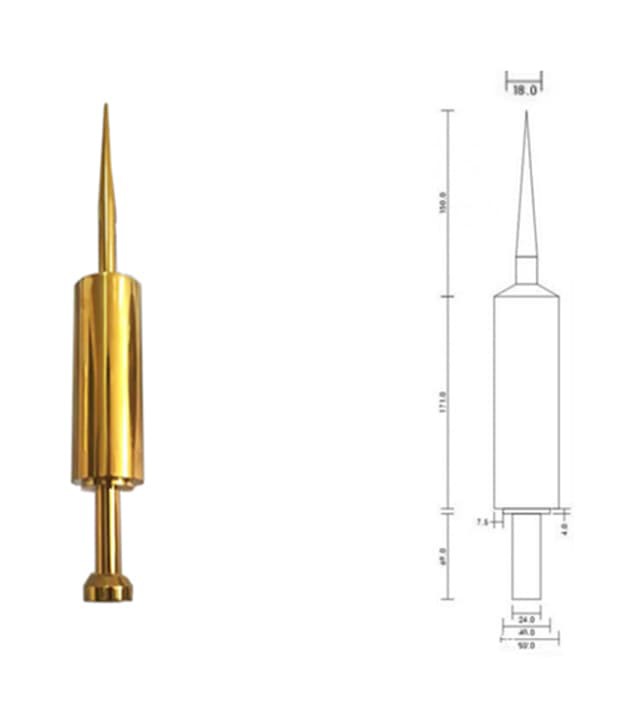

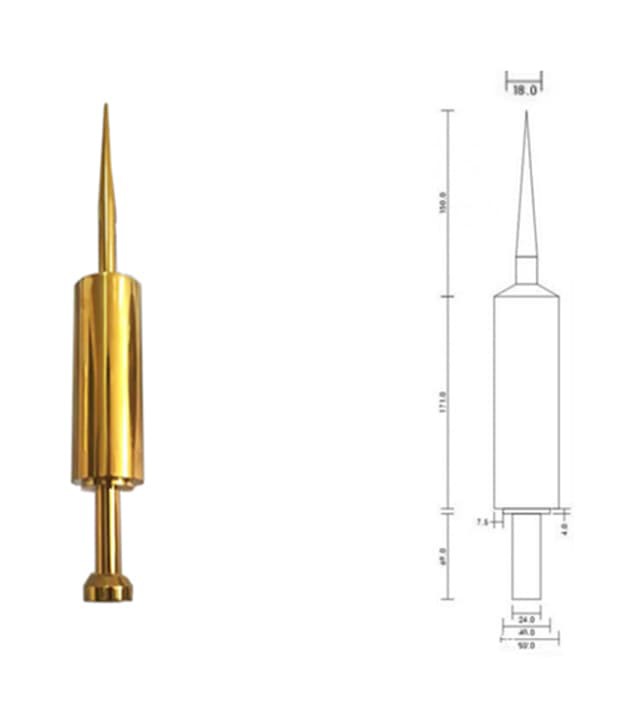

| Product name/model | Titanium alloy lightning rod |

| Maximum discharge current (KA) | ≥500 |

| Wind resistance ≤ (m/s) | 210km/h |

| Exciter diameter (mm) | 72 |

| Impedance change body diameter x height (mm) | 175 |

| Weight (kg) | 4 |

| Total height (mm) | 600+10 |

| Flange specification φ (mm) | User-defined |