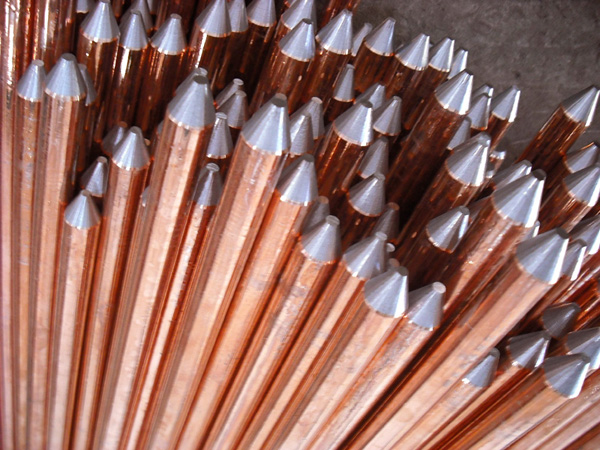

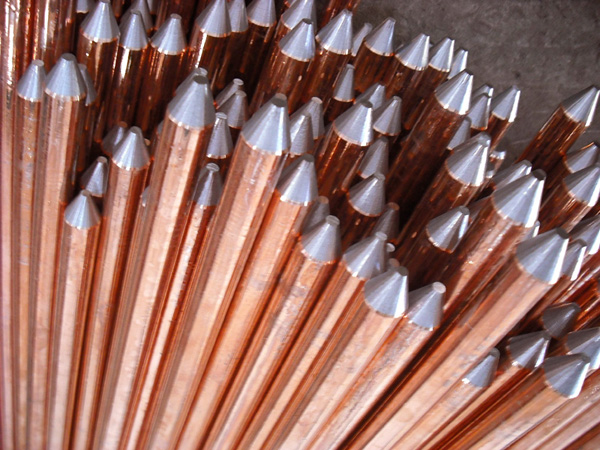

Copper-clad steel ground rod is made by an advanced manufacturing process, making purity of 99.9% electrolytic copper and low carbon steel electrolyze and electroforming, with a coated copper thickness of more than 0.25mm. The advantage is that tensile strength(a collection of properties of steel), corrosion resistance(life of 30 years or more), widely used, safe and reliable connection, and quick and easy installation, greatly reducing costs.

Copper-clad steel ground rod has strong protection, whether naturally deep underground after corrosion or electrochemical reaction. Ground rods and ground connections that use our company's thermal welding powder for exothermic welding, make sure the complete grounding device is under the protection of copper, and is a true maintenance-free grounding device.

Copper clad steel ground rod with coaxial connector, drive head, drill bits, and other accessories, according to different geology and requirements, can be made of bass coaxial connector(bolts) connection, any increase in the length of electroplating copper grounding rods. Entry side with the drive head(bolts)connection for to combat the use of deep wreck. End top use a special drill bit (bolts) connection, so deep in the wreck.

Product Features:

1. Copper-coated and steel rods achieve the type of molecular combination, grounding rod deep in the earth, not bend and break.

2. The copper-coated uniform, high purity copper, strength steel core.

3. Strong corrosion resistance, non-tout line, non-warping, non-cracking.

4. Perfect conductive performance, and stability electrical performance.

Data Parameters:

1. 99.9% pure copper and Q235low carbon steel.

2. Copper-coated thickness of more than 0.254mm.

3. Tensile strength more than 600N/mm2.

4. Flatness error less than 1mm/m.

5. Copper layer plasticity: Ground rod(wire) bent 30 degrees, no cracks inside and outside edge knuckle phenomenon.

6. Copper layer combined degree: the adhesion test, except the tiger clamp jaws bite outer copper layer sar epee led off, and the remaining parts of the copper-steel good combination, not appear peeling, connect the required length of grounding rods, can be 30 meters deep underground, and not subject to any increase soil resistivity and ground resistance climatic condition(frost and drought) effects.

7. Normal thread: 1/2”,5/8”,M16,3/4”,M20,M22 and M27.

8. Normal copper layer: 0.025mm,0.05mm,0.1mm,0.125mm,0.15mm,0.2mm,0.254mm,0.33mm.

9. Normal shape: two ends threaded, one end flat and one end tipped, one end threaded one end tipped, etc.