Overview

Power Fuses are especially suited for protecting transformers, capacitor banks, and cables in outdoor distribution substations through 34.5 kV. They incorporate precision-engineered nondamageable silver or nickel-chrome fusible elements with time-current characteristics that are precise and permanently accurate — assuring not only dependable performance, but also continued reliability of system coordination plans.

With Power Fuses, source-side devices may be set for faster operation than practical with other power fuses or circuit breakers, thereby providing better system protection without compromising coordination.

Features:

UNI-20 Power Fuses, rated 200 amperes continuous, utilize UNI-20 Fuse Units. These fuse units are offered in a variety of ampere ratings, in five different speeds fuse link type “K,” Standard, Slow, Very Slow, and “DR.” They provide interrupting ratings of up to 14,000 amperes symmetrical at 60 Hz.

UNI-40 Power Fuses, rated 400 amperes continuous, utilize UNI-40 Fuse Units. These fuse units are similarly offered in a variety of ampere ratings, in four different speeds — fuse link type “K”, Standard, Slow, and Very Slow. They provide interrupting ratings of up to 25,000 amperes symmetrical at 60 Hz.

This broad selection of ampere ratings and speeds permits close fusing to achieve maximum protection and optimum coordination. UNI-20 and UNI-40 Power Fuses are manufactured in accordance with a quality system certified to ISO9001:2000.

Fault interruption:

Fast, positive fault interruption is achieved in UNI-20 and UNI-40 Fuse Units through high-speed elongation of the arc in the solid-material-lined bore, and by the efficient deionizing action of gases generated through thermal reaction of the solid material due to the heat of the confined arc. The resultant high rate of dielectric recovery voltage more than matches the transient recovery voltage severity of the circuit.

Here’s How it Works

Overcurrent melts the fusible element, shown below. The strain wire severs, initiating arcing.

Released force of the drive spring accelerates the arcing rod upward, causing rapid elongation of the arc in the solid-material-lined bore.Under maximum fault conditions, heat from the confined arc causes solid material in the large-diameter lower section of the arc-extinguishing chamber to undergo thermal reaction, generating turbulent gases and effectively enlarging the bore diameter so that the arc energy is released with a mild exhaust. Under low-to-moderate fault conditions, the arc is extinguished in the small-diameter upper section of the arc-extinguishing chamber, where deionizing gases are effectively concentrated for efficient arc extinction.

Continued upward travel of the arcing rod after arc extinction causes the actuating pin to penetrate the upper seal, initiating positive dropout of the fuse unit.

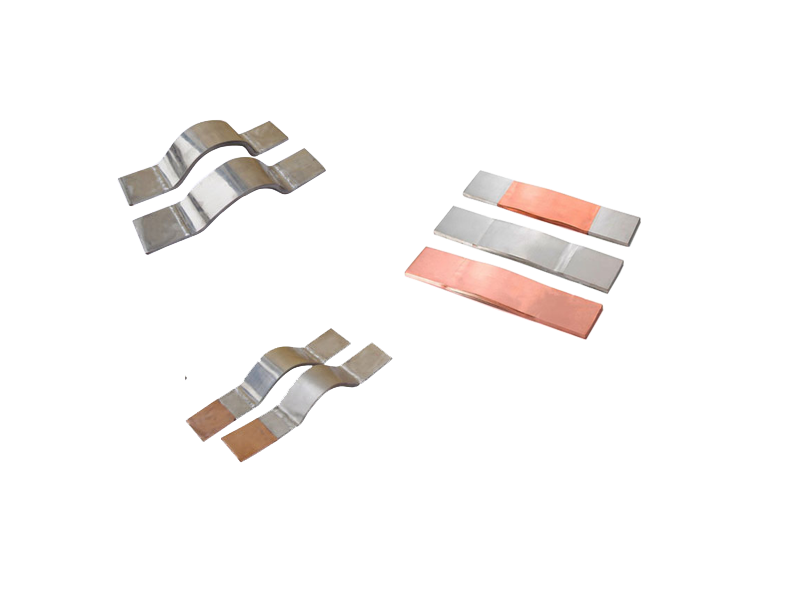

Fuse Units Fusible Element

Cutout Fuse Units feature silver or pretensioned nickel-chrome current-responsive elements that are drawn through precision dies to very accurate diameters. They’re of solderless construction, brazed into their terminals. Melting time-current characteristics are precise, with only 10% total tolerance in melting current, compared to the 20% tolerance of many fuses.

These design and construction features assure that Cutout Fuse Units conform to their time-current characteristics on a sustained basis. Cutout Fuse Units are corrosion-resistant and nondamageable. Age, vibration, and surges that heat the element nearly to the severing point won’t affect their characteristics.

The nondamageability of Cutout Fuse Units provides these important advantages:

Superior transformer protection. You can fuse close to the transformer full-load current and thus protect against a broad range of secondary-side faults.

Parameter

Power Fuses are especially suited for protecting transformers, capacitor banks, and cables in outdoor distribution substations through 34.5 kV. They incorporate precision-engineered nondamageable silver or nickel-chrome fusible elements with time-current characteristics that are precise and permanently accurate — assuring not only dependable performance, but also continued reliability of system coordination plans.

With Power Fuses, source-side devices may be set for faster operation than practical with other power fuses or circuit breakers, thereby providing better system protection without compromising coordination.

Features:

UNI-20 Power Fuses, rated 200 amperes continuous, utilize UNI-20 Fuse Units. These fuse units are offered in a variety of ampere ratings, in five different speeds fuse link type “K,” Standard, Slow, Very Slow, and “DR.” They provide interrupting ratings of up to 14,000 amperes symmetrical at 60 Hz.

UNI-40 Power Fuses, rated 400 amperes continuous, utilize UNI-40 Fuse Units. These fuse units are similarly offered in a variety of ampere ratings, in four different speeds — fuse link type “K”, Standard, Slow, and Very Slow. They provide interrupting ratings of up to 25,000 amperes symmetrical at 60 Hz.

This broad selection of ampere ratings and speeds permits close fusing to achieve maximum protection and optimum coordination. UNI-20 and UNI-40 Power Fuses are manufactured in accordance with a quality system certified to ISO9001:2000.

Fault interruption:

Fast, positive fault interruption is achieved in UNI-20 and UNI-40 Fuse Units through high-speed elongation of the arc in the solid-material-lined bore, and by the efficient deionizing action of gases generated through thermal reaction of the solid material due to the heat of the confined arc. The resultant high rate of dielectric recovery voltage more than matches the transient recovery voltage severity of the circuit.

Here’s How it Works

Overcurrent melts the fusible element, shown below. The strain wire severs, initiating arcing.

Released force of the drive spring accelerates the arcing rod upward, causing rapid elongation of the arc in the solid-material-lined bore.Under maximum fault conditions, heat from the confined arc causes solid material in the large-diameter lower section of the arc-extinguishing chamber to undergo thermal reaction, generating turbulent gases and effectively enlarging the bore diameter so that the arc energy is released with a mild exhaust. Under low-to-moderate fault conditions, the arc is extinguished in the small-diameter upper section of the arc-extinguishing chamber, where deionizing gases are effectively concentrated for efficient arc extinction.

Continued upward travel of the arcing rod after arc extinction causes the actuating pin to penetrate the upper seal, initiating positive dropout of the fuse unit.

Fuse Units Fusible Element

Cutout Fuse Units feature silver or pretensioned nickel-chrome current-responsive elements that are drawn through precision dies to very accurate diameters. They’re of solderless construction, brazed into their terminals. Melting time-current characteristics are precise, with only 10% total tolerance in melting current, compared to the 20% tolerance of many fuses.

These design and construction features assure that Cutout Fuse Units conform to their time-current characteristics on a sustained basis. Cutout Fuse Units are corrosion-resistant and nondamageable. Age, vibration, and surges that heat the element nearly to the severing point won’t affect their characteristics.

The nondamageability of Cutout Fuse Units provides these important advantages:

Superior transformer protection. You can fuse close to the transformer full-load current and thus protect against a broad range of secondary-side faults.

Parameter

| Rated(KV) | Rated current(A) | Rated interrupting current(KA) | Lighting impulse withstand voltage to ground(BIL KV) | Minimum powerfrequency withstand dry voltage to ground(KV) | Minimum creepage distance(mm) |

| 11-15 | 100/200 | 12 | 110 | 42 | 220 |

| 11-15 | 100/200 | 12 | 125 | 50 | 320 |

| 24-27 | 100/200 | 12 | 150 | 65 | 470 |

| 33-38 | 100/200 | 8 | 170 | 70 | 660 |

| 33-38 | 100/200 | 8 | 170 | 70 | 720 |

| 33-38 | 100/200 | 8 | 170 | 70 | 900 |