Application

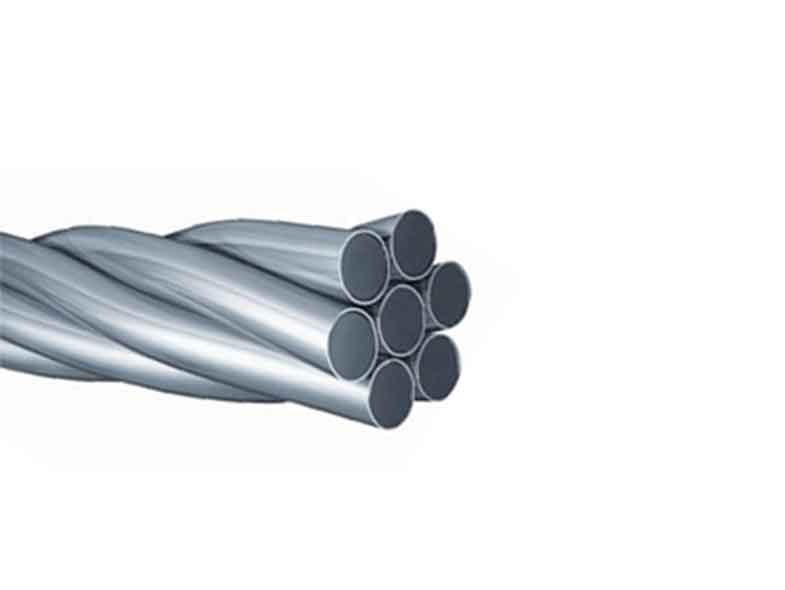

Aluminum-clad steel wire, commonly abbreviated as AW or AS or AC.

AW : Aluminum-clad steel wire as per ASTM B 502 Standard.

AS : Aluminum-clad steel wire as per IEC 61232 Standard.

AC : Aluminum-clad steel wire as per AS 3607 Standard.

The covered aluminum steel wire for compression, internationally known as Alumoweld or ACS, is a wire of high resistance whose cover is carried through an extrusion process, that adheres the aluminum by pressure and heat.

Manufacture of bare overhead conductor, OPGW, ground wire,Overhead ground wire, messenger wire, guy wire, formed wire for protecting, terminating and splicing transmission and distribution lines,shield wire protecting transmission lines against lightning damage fence, barber wire and hardware.

Alumo-clad steel wire and strand is used by power utilities as well as formed wire and optical ground wire manufacturers.

ACSR/AW Core Wire and Strand

Its high strength, excellent conductivity, impressive corrosion resistance and compatibility with solid aluminum wire make aluminum clad steel products highly desirable as a reinforcing material for ACSR conductors (ACSR/AW).

Formed Wire

Aluminum coated products are made with a special, malleable steel core in its formed wire solution. When used with other connectors and anchors, you guarantee a metallurgical compatibility that eliminates conflicts between dissimilar metals and matches the life expectancy of the conductor or guy wire.

Guy Wire

Aluminum guy wire is non-rusting, high-strength for electrical distribution and transmission lines, communications and signal lines, antenna towers, masts, stacks and other structures. The high tensile strength of this lightweight strand is permanently protected against corrosion by a thick cladding of aluminum.

Messenger Wire

Communications cables require the same superior grade of messenger strand as power cables. Messenger wire ensures a long life, will not rust and maintains its original strength.

Overhead Ground Wire

Aluminum clad steel overhead ground wires offer protection against lightning for transmission lines carrying large blocks of power while providing a combination of conductivity, corrosion resistance and high strength.

Specification

based upon international standard IEC6 1232, EN 61.232 and ASTM B-415 ASTM B502

Features

Aluminum clad steel product features include:

Corrosion resistant in industrial, semi-industrial and marine environments

Superior to aluminized steel

Lightweight

Same tensile strength as extra high strength steel but weighs 15 percent less

Excellent conductivity–much more conductive than galvanized steel and aluminum

ASTM B416

DIN 48201

IEC 61232

ASTM B 415-02

1, Tensile Requirement

2, Physical Constants

3, Wire Diameter Variations

4, Aluminum Thickness and Resistance

ASTM B 502-02

Aluminum-Clad Steel Core Wire for Aluminum Conductors, Aluminum-Clad Steel Reinforced

Wire Diameter Variations

ALUMINUM CLAD STEEL CONDUCTOR (ACS) - EN 50182

Aluminum-clad steel wire, commonly abbreviated as AW or AS or AC.

AW : Aluminum-clad steel wire as per ASTM B 502 Standard.

AS : Aluminum-clad steel wire as per IEC 61232 Standard.

AC : Aluminum-clad steel wire as per AS 3607 Standard.

The covered aluminum steel wire for compression, internationally known as Alumoweld or ACS, is a wire of high resistance whose cover is carried through an extrusion process, that adheres the aluminum by pressure and heat.

Manufacture of bare overhead conductor, OPGW, ground wire,Overhead ground wire, messenger wire, guy wire, formed wire for protecting, terminating and splicing transmission and distribution lines,shield wire protecting transmission lines against lightning damage fence, barber wire and hardware.

Alumo-clad steel wire and strand is used by power utilities as well as formed wire and optical ground wire manufacturers.

ACSR/AW Core Wire and Strand

Its high strength, excellent conductivity, impressive corrosion resistance and compatibility with solid aluminum wire make aluminum clad steel products highly desirable as a reinforcing material for ACSR conductors (ACSR/AW).

Formed Wire

Aluminum coated products are made with a special, malleable steel core in its formed wire solution. When used with other connectors and anchors, you guarantee a metallurgical compatibility that eliminates conflicts between dissimilar metals and matches the life expectancy of the conductor or guy wire.

Guy Wire

Aluminum guy wire is non-rusting, high-strength for electrical distribution and transmission lines, communications and signal lines, antenna towers, masts, stacks and other structures. The high tensile strength of this lightweight strand is permanently protected against corrosion by a thick cladding of aluminum.

Messenger Wire

Communications cables require the same superior grade of messenger strand as power cables. Messenger wire ensures a long life, will not rust and maintains its original strength.

Overhead Ground Wire

Aluminum clad steel overhead ground wires offer protection against lightning for transmission lines carrying large blocks of power while providing a combination of conductivity, corrosion resistance and high strength.

Specification

based upon international standard IEC6 1232, EN 61.232 and ASTM B-415 ASTM B502

Features

Aluminum clad steel product features include:

Corrosion resistant in industrial, semi-industrial and marine environments

Superior to aluminized steel

Lightweight

Same tensile strength as extra high strength steel but weighs 15 percent less

Excellent conductivity–much more conductive than galvanized steel and aluminum

ASTM B416

| Code Number | Area | No. of wires | Diameters | Weight | Rated Strength | DC Resistance | |

| mm2 | wire | conductor | kg/km | kN | ohm/km | ||

| 3 No 5 Awg. | 50,32 | 3 | 4,62 | 9,96 | 334,1 | 54,42 | 1.699 |

| 3 No 6 Awg. | 39 ,00 | 3 | 4,11 | 8,87 | 265,0 | 45,74 | 2.142 |

| 3 No 7 Awg. | 31,65 | 3 | 3,67 | 7,90 | 210,1 | 38,36 | 2.701 |

| 3 No 8 Awg. | 25,10 | 3 | 3,26 | 7,03 | 166,7 | 32,06 | 3.406 |

| 3 No 9 Awg. | 19,90 | 3 | 2,91 | 6,26 | 132,2 | 25,43 | 4.294 |

| 3 No 10 Awg. | 15,78 | 3 | 2,59 | 5,58 | 104,8 | 20,16 | 5.415 |

| 7 No 5 Awg. | 117,40 | 7 | 4,62 | 13,90 | 781,1 | 120,27 | 0,7426 |

| 7 No 6 Awg. | 93,10 | 7 | 4,11 | 12,40 | 619,5 | 101,14 | 0,9198 |

| 7 No 7 Awg. | 73,87 | 7 | 3,67 | 11,00 | 491,1 | 84,81 | 1.16 |

| 7 No 8 Awg. | 58,56 | 7 | 3,26 | 9,78 | 389,6 | 70,88 | 1.463 |

| 7 No 9 Awg. | 46,44 | 7 | 2,91 | 8,71 | 308,9 | 56,20 | 1.844 |

| 7 No 10 Awg. | 36,83 | 7 | 2,59 | 7,76 | 245,1 | 44,58 | 2.325 |

| 7 No 11 Awg. | 29,21 | 7 | 2,30 | 6,91 | 194,4 | 35,35 | 2.932 |

| 7 No 12 Awg. | 23,16 | 7 | 2,05 | 6,16 | 154,2 | 28,03 | 3.697 |

| 19 No 5 Awg. | 318,70 | 19 | 4,62 | 23,10 | 2129,0 | 326,39 | 0,2698 |

| 19 No 6 Awg. | 252,70 | 19 | 4,11 | 20,60 | 1688,0 | 274,55 | 0,3402 |

| 19 No 7 Awg. | 200,40 | 19 | 3,67 | 18,30 | 1339,0 | 230,18 | 0,4290 |

| 19 No 8 Awg. | 158,90 | 19 | 3,26 | 16,30 | 1062,0 | 192,41 | 0,5409 |

| 19 No 9 Awg. | 126,10 | 19 | 2,91 | 14,50 | 842,0 | 152,58 | 0,6821 |

| 19 No 10 Awg. | 99,96 | 19 | 2,59 | 12,90 | 667,7 | 121,00 | 0,8601 |

| 37 No 5 Awg. | 620,60 | 37 | 4,62 | 32,30 | 4170,0 | 635,43 | 0,1394 |

| 37 No 6 Awg. | 492,20 | 37 | 4,11 | 28,80 | 3307,0 | 534,85 | 0,1757 |

| 37 No 7 Awg. | 390,30 | 37 | 3,67 | 25,70 | 2623,0 | 448,09 | 0,2216 |

| 37 No 8 Awg. | 309,50 | 37 | 3,26 | 22,90 | 2080,0 | 374,67 | 0,2794 |

| 37 No 9 Awg. | 245,50 | 37 | 2,91 | 20,30 | 1649,0 | 279,11 | 0,3523 |

| 37 No 10 Awg. | 194,70 | 37 | 2,59 | 17,90 | 1308,0 | 235,61 | 0,4443 |

| Code Number | Area | No. of wires | Diameters(mm) | Weight | Rated Strength | DC Resistance | |

| mm2 | mm2 | wire | conductor | kg/km | kN | ohm/km | |

| 25 | 24.25 | 7 | 2.1 | 6.3 | 162 | 31.56 | 3.546 |

| 35 | 34.36 | 7 | 2.5 | 7.5 | 229 | 44.72 | 2.499 |

| 50 | 49.48 | 7 | 3 | 9 | 330 | 64.4 | 1.736 |

| 70 | 65.81 | 19 | 2.1 | 10.5 | 441 | 85.65 | 1.313 |

| 95 | 93.27 | 19 | 2.5 | 12.5 | 626 | 121.39 | 0.925 |

| 120 | 116.99 | 19 | 2.8 | 14 | 785 | 152.26 | 0.737 |

| 150 | 147.11 | 37 | 2.25 | 15.7 | 990 | 191.46 | 0.587 |

| 185 | 181.62 | 37 | 2.5 | 17.5 | 1221 | 236.38 | 0.476 |

| 240 | 242.54 | 61 | 2.25 | 20.2 | 1635 | 299.05 | 0.357 |

| Class | 20SA | 27SA | 30SA | 40SA | ||||||||

| Type | A | B | - | - | - | |||||||

| Tolerance on diameter | Ø ≥ 2,67 mm | ± 1,5% | ± 1,5% | ± 1,5% | ± 1,5% | ± 1,5% | ||||||

| Ø < 2,67 mm | ± 0,04 mm | ± 0,04 mm | ± 0,04 mm | ± 0,04 mm | ± 0,04 mm | |||||||

| Minimum thickness of aluminium clad (% of radius) | 8% if Ø < 1,80 mm | |||||||||||

| 10% if Ø ≥ 1,80 mm | 14% | 15% | 25% | |||||||||

| Nominal density at 20°C (g/cm³) | 6,59 | 6,53 | 5,91 | 5,61 | 4,64 | |||||||

| Resistivity at 20°C max. (nΩ x m) | 84,80 | 84,80 | 63,86 | 57,47 | 43,10 | |||||||

| Conductivity (IACS) | 20,3% | 20,3% | 27% | 30% | 40% | |||||||

| Final modulus of elasticity (GPa) | 162 | 155 | 140 | 132 | 109 | |||||||

| Coefficient of linear expansion (K-1) | 13,0 x 10-6 | 12,6 x 10-6 | 13,4 x 10-6 | 13,8 x 10-6 | 15,5 x 10-6 | |||||||

| Constant-mass temperature coefficient of resistance (K-1) | 0,0036 | 0,0036 | 0,0036 | 0,0038 | 0,0040 | |||||||

| MECHANICAL PROPERTIES | ||||||||||||

| class | type | nominal diameter (mm) | min. tensile strength (N/mm²) | min. stress at 1% extension | elongation | torsion test (min. twists) | ||||||

| 1,24 | 3,25 | 1340 | 1200 | |||||||||

| 3,26 | 3,45 | 1310 | 1180 | |||||||||

| 3,46 | 3,65 | 1270 | 1140 | |||||||||

| 3,66 | 3,95 | 1250 | 1100 | |||||||||

| A | 3,96 | 4,10 | 1210 | 1100 | ||||||||

| 20SA | 4,11 | 4,40 | 1180 | 1070 | ||||||||

| 4,41 | 4,60 | 1140 | 1030 | 1,5% | 20 | |||||||

| 4,61 | 4,75 | 1100 | 1000 | |||||||||

| 4,76 | 5,50 | 1070 | 1000 | |||||||||

| B | 1,24 | 5,50 | 1320 | 1100 | ||||||||

| 27SA | - | 2,50 | 5,00 | 1080 | 800 | |||||||

| 30SA | - | 2,50 | 5,00 | 880 | 650 | |||||||

| 40SA | - | 2,50 | 5,00 | 680 | 500 | |||||||

1, Tensile Requirement

| Nominal Diameter, in./mm | Size,聽 | 20.30% | 27% | 30% | 40% | |||||

| AWG | psi | MPa | psi | MPa | psi | MPa | psi | MPa | ||

| 0.2043 | 5.19 | 4 | 155 000 | 1070 | 125 000 | 862 | 102 000 | 703 | 80 000 | 552 |

| 0.188 | 4.78 | 160 000 | 1100 | 129 000 | 889 | 106 000 | 731 | 84 000 | 579 | |

| 0.1819 | 4.62 | 5 | 165 000 | 1140 | 133 000 | 917 | 110 000 | 758 | 88 000 | 607 |

| 0.1729 | 4.39 | 170 000 | 1170 | 137 000 | 945 | 114 000 | 786 | 92 000 | 634 | |

| 0.162 | 4.11 | 6 | 175 000 | 1210 | 141 000 | 972 | 114 000 | 786 | 96 000 | 662 |

| 0.1549 | 3.93 | 180 000 | 1240 | 145 000 | 1000 | 118 000 | 814 | 96 000 | 662 | |

| 0.1443 | 3.67 | 7 | 185 000 | 1280 | 150 000 | 1034 | 122 000 | 841 | 98 000 | 676 |

| 0.1369 | 3.48 | 190 000 | 1310 | 154 000 | 1062 | 126 000 | 869 | 98 000 | 676 | |

| 0.1285 | 3.26 | 8 | 195 000 | 1340 | 156 000 | 1076 | 128 000 | 883 | 99 500 | 686 |

| 0.1144 | 3.91 | 9 | 195 000 | 1340 | 156 000 | 1076 | 128 000 | 883 | 99 500 | 686 |

| 0.1019 | 2.59 | 10 | 195 000 | 1340 | 156 000 | 1076 | 128 000 | 883 | 99 500 | 686 |

| 0.0907 | 2.3 | 11 | 195 000 | 1340 | 156 000 | 1076 | 128 000 | 883 | 99 500 | 686 |

| 0.0808 | 2.05 | 12 | 195 000 | 1340 | 156 000 | 1076 | 128 000 | 883 | 99 500 | 686 |

| % | Density at 20°C | Modulus of Elasticity psi | Coef. of Linear Exp. | Temperature Coef. of Resistance |

| Conductivity | ||||

| 20.3 | 0.2381 lb/in3 | 23.5×106 | 0.0000072/°F (0.0000126/℃) | 0.0020/°F (0.0036/℃) |

| (6.59 g/cm3) | (162 GPa) | |||

| 27 | 0.2135 lb/in3 | 20.3×106 | 0.0000077/°F (0.0000134/℃) | 0.0020/°F (0.0036/℃) |

| (5.91 g/cm3) | (140 GPa) | |||

| 30 | 0.2027 lb/in3 | 19.1×106 | 0.0000079/°F (0.0000138/℃) | 0.0021/°F (0.0038/℃) |

| (5.61 g/cm3) | (132 GPa) | |||

| 40 | 0.1676 lb/in3 | 15.8×106 | 0.0000089/°F (0.0000155/℃) | 0.0022/°F (0.0040/℃) |

| (4.64 g/cm3 ) | (109 GPa) |

| Specified Diameter, in. | Permissible Variations in Specified Diameter, plus and minus |

| 0.2043 to 0.1000,incl | 1.50% |

| 0.1000 to 0.0800,incl | 0.0015 in. (0.038mm) |

| % Conductivity | % of Nominal Wire Radius | D.C. Resistance at 20℃ |

| 20.3 | 10% | 51.01 Ω·cmil/ft |

| 27 | 14% | 38.41 Ω·cmil/ft |

| 30 | 15% | 34.57 Ω·cmil/ft |

| 40 | 25% | 25.93 Ω·cmil/ft |

Aluminum-Clad Steel Core Wire for Aluminum Conductors, Aluminum-Clad Steel Reinforced

- Tensile Requirements

| Nominal Diameter in.(mm) |

Stress at 1% Extension min. psi(MPa) | Ultimate Tensile Strength min. psi(MPa) | Elongation min |

| %,10in. (250mm) | |||

| 0.0770 to 0.1289 (1.956 to 3.274).,incl 0.1290 to 0.1396 (3.275 to 3.477).,incl 0.1370 to 0.1443 (3.478 to 3.665).,incl 0.1444 to 0.1549 (3.666 to 3.934).,incl 0.1550 to 0.1620 (3.935 to 4.115).,incl 0.1621 to 0.1729 (4.116 to 4.392).,incl 0.1730 to 0.1819 (4.393 to 4.620).,incl 0.1820 to 0.1880 (4.621 to 4.775).,incl |

|||

| 175 000(1206) | 195 000(1344) | 1.5 | |

| 170 000(1172) | 190 000(1310) | 1.5 | |

| 165 000(1137) | 185 000(1275) | 1.5 | |

| 160 000(1103) | 180 000(1241) | 1.5 | |

| 175 000(1206) | 1.5 | ||

| 155 000(1068) | 170 000(1172) | 1.5 | |

| 150 000(1034) | 165 000(1137) | 1.5 | |

| 145 000(1100) | 160 000(1103) | 1.5 |

| Nominal Diameter in.(mm) | Permissible Variations in Nominal Diameter |

| 0.0770 to 0.0999 | 0.0015in,(0.038mm) |

| (2.538 to 4.775),incl | 1.50% |

| Code Name | Sectional Area | Stranding | Overall Diameter of | Weight | D C Resistance at | Rated Strength | |

| No. of Wires | Individual wire diameter | Conductor | 20°C | ||||

| mm² | No. | mm | mm | Kg/km | Ω/Km | KN | |

| 24-A20SA | 24.2 | 7 | 2.1 | 6.3 | 161.5 | 3.5364 | 32.49 |

| 34-A20SA | 34.4 | 7 | 2.5 | 7.5 | 229 | 2.4953 | 46.04 |

| 49-A20SA | 49.5 | 7 | 3 | 9 | 329.7 | 1.7328 | 66.3 |

| 66-A20SA | 65.8 | 19 | 2.1 | 10.5 | 441 | 1.3102 | 88.18 |

| 93-A20SA | 93.3 | 19 | 2.5 | 12.5 | 624.9 | 0.9245 | 124.98 |

| 117-A20SA | 117 | 19 | 2.8 | 14 | 783.9 | 0.737 | 156.77 |

| 147-A20SA | 147.1 | 37 | 2.25 | 15.8 | 989.2 | 0.5881 | 197.13 |

| 182-A20SA | 181.6 | 37 | 2.5 | 17.5 | 1 221.2 | 0.4764 | 243.38 |

| 243-A20SA | 242.5 | 61 | 2.25 | 20.3 | 1 636.1 | 0.3579 | 325 |

| 299-A20SA | 299.4 | 61 | 2.5 | 22.5 | 2 019.8 | 0.2899 | 401.24 |