Description

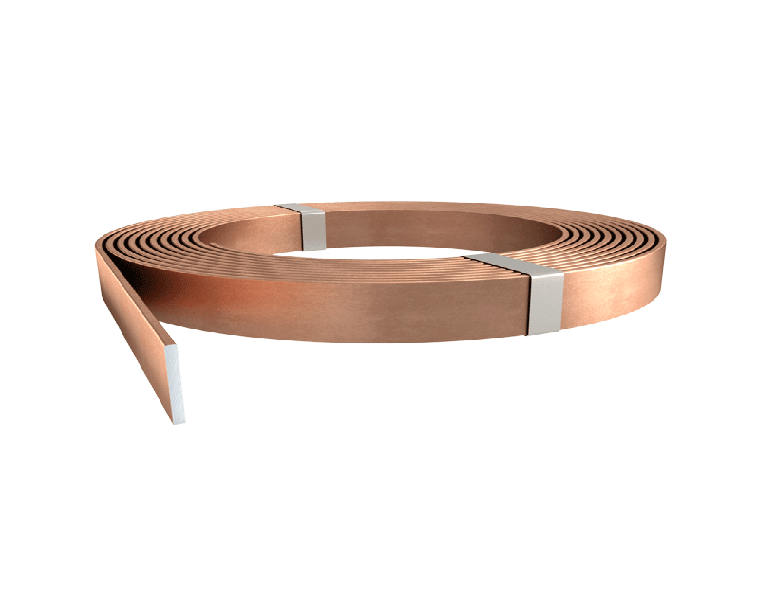

Copper earth strip / tape / earthing strip is referred to as copper grounding bar, also known as copper busbar, it is a long conductor made of copper, rectangular or chamfered (rounded) rectangle, made of aluminum material. The so-called aluminum row is produced to carry current and connect electrical equipment in the circuit. At present, the quality requirements of the copper earth strip are implemented in the GB/T5585.1-2005 standard.

It is a kind of high-current conductive product, suitable for high and low voltage electrical appliances, switch contacts, power distribution equipment, busway and other electrical engineering, and is also widely used in metal smelting, electroplating, chemical caustic soda and other super-current electrolysis smelting projects.

Typically, copper earth tapes are used as HV electrodes for standard earthing arrangements on ground mounted LV MV HV substations – the earth tape functions as a perimeter electrode installed to the outer edges of the foundation in direct contact with the soil and connected to the switchgear earth bars. The copper tape will provide protection to exposed and normally un-energised conductive metalwork within the substation perimeter fence including panels, kiosks, lighting towers and oil tanks.

Product application

1) Thickness: 0.15mm - 3.0mm

2) Width: 610mm max. Coil weight: 3 ton Max

3) Normal Sizes:

3mm*25mm*50m

3mm*25mm*15m

6mm*50mm*50m

(or customize according to your needs)

4) Grade: C1100, C1020

5) Chemical Composition: C1100: Cu >99.90%, C1020:

Cu >99.96%

6) Oxygen content: C1100: O < 500ppm, C1020: O < 50ppm

7) Temper: O, 1/4H, 1/2H, H

O: HV<70; 1/4H:HV 65-85; 1/2H:HV 80-100; H:HV >1

Features

1) High corrosion resistance

2) High electrical conductivity and durability

3) High precision and low cost

4) Narrow size tolerances

5) Low-fat, smooth surface

6) Concentrated materials composition

7) High dimensional stability

8) Mechanical and physical properties can be controlled

9) Wide range of sizes and almost zero maintenance

10) Excellent malleability, can be forged the broadest, thinnest and longest, etc.

Technical Information

Product Size

Copper earth strip / tape / earthing strip is referred to as copper grounding bar, also known as copper busbar, it is a long conductor made of copper, rectangular or chamfered (rounded) rectangle, made of aluminum material. The so-called aluminum row is produced to carry current and connect electrical equipment in the circuit. At present, the quality requirements of the copper earth strip are implemented in the GB/T5585.1-2005 standard.

It is a kind of high-current conductive product, suitable for high and low voltage electrical appliances, switch contacts, power distribution equipment, busway and other electrical engineering, and is also widely used in metal smelting, electroplating, chemical caustic soda and other super-current electrolysis smelting projects.

Typically, copper earth tapes are used as HV electrodes for standard earthing arrangements on ground mounted LV MV HV substations – the earth tape functions as a perimeter electrode installed to the outer edges of the foundation in direct contact with the soil and connected to the switchgear earth bars. The copper tape will provide protection to exposed and normally un-energised conductive metalwork within the substation perimeter fence including panels, kiosks, lighting towers and oil tanks.

Product application

1) Thickness: 0.15mm - 3.0mm

2) Width: 610mm max. Coil weight: 3 ton Max

3) Normal Sizes:

3mm*25mm*50m

3mm*25mm*15m

6mm*50mm*50m

(or customize according to your needs)

4) Grade: C1100, C1020

5) Chemical Composition: C1100: Cu >99.90%, C1020:

Cu >99.96%

6) Oxygen content: C1100: O < 500ppm, C1020: O < 50ppm

7) Temper: O, 1/4H, 1/2H, H

O: HV<70; 1/4H:HV 65-85; 1/2H:HV 80-100; H:HV >1

Features

1) High corrosion resistance

2) High electrical conductivity and durability

3) High precision and low cost

4) Narrow size tolerances

5) Low-fat, smooth surface

6) Concentrated materials composition

7) High dimensional stability

8) Mechanical and physical properties can be controlled

9) Wide range of sizes and almost zero maintenance

10) Excellent malleability, can be forged the broadest, thinnest and longest, etc.

Technical Information

| Material | Pure copper |

| Size | Custom made |

| Life | More than 50 Years |

| Characters | Easy installation, good conductivity |

| Certification | ISO9001 |

| Product specifications | Length(m/roll) | Weight (kg/m) |

| TMR-25×3 | 50-100 | 0.6675 |

| TMR-30×3 | 50-100 | 0.801 |