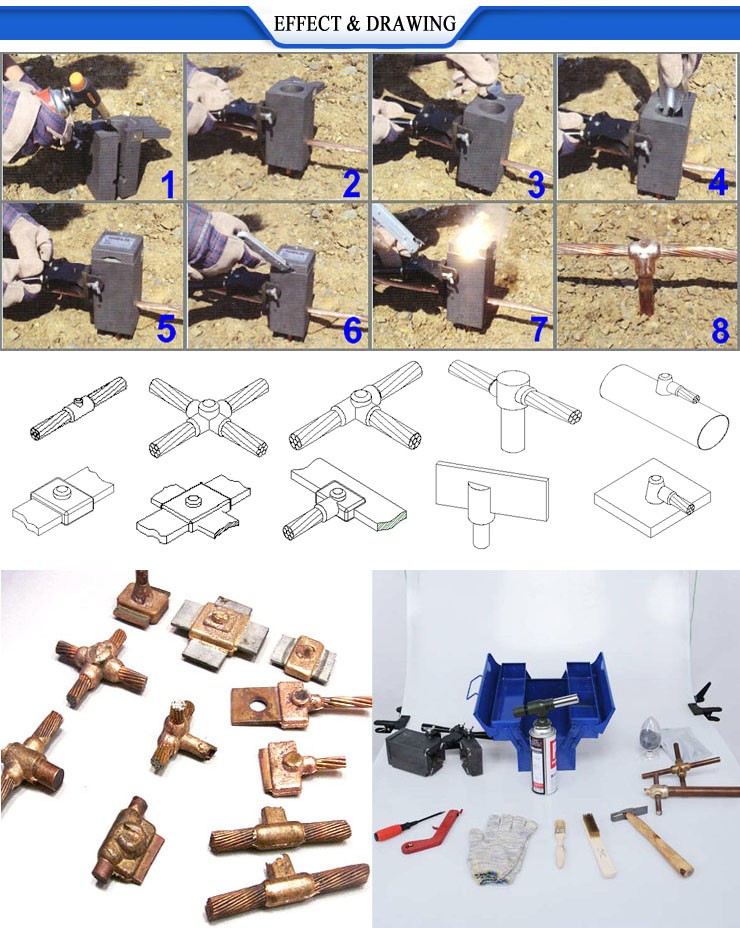

Exothermic Welding is a main material for grounding grid welding. It consists of copper-based thermite flux and graphite mold clamps. The principle is that the redox reaction of copper oxide and aluminum alloy reducing agents in corresponding proportions generates copper and a large amount of heat energy, producing high-temperature copper liquid, and the welding process is realized with the help of graphite molds.

The solder joints that can be welded by

Exothermic Welding have good electrical conductivity, easy operation and construction, and stable quality. They are a reasonable welding method for ground connection. It is widely used in the fields of electric power, petrochemicals, and mobile communications.

The Exothermic Welding is suitable for the connection between copper and copper, the connection between copper and steel, the connection between steel and steel, the connection between copper clad steel and copper clad steel, the connection between copper clad steel and copper, the connection between copper clad steel and steel. Welding between different materials such as inter-connection. In China, the development of exothermic welding technology is relatively backward. Due to technical limitations, domestic exothermic welding technology did not develop until after 2006. Prior to this, some large and small domestic projects specified the use of imported exothermic welding technology. At that time, some foreign exothermic welding technology brands were used in China, and even the names of Exothermic Welding were quite different.

The grounding main wires in substations are often made of copper-clad steel. Copper-clad steel is a layer of copper plated on the outside of the steel. Because copper has good conductivity and high oxidation resistance, in order to maintain and enhance the copper-clad steel material Performance, Exothermic Welding is the soldering method that can be used. Similarly for all subway projects, the welding method of the grounded copper-clad steel of the subway is also specified to use

Exothermic Welding. In some major power grid projects, new copper-clad steel strands are used as grounding materials, and the welding of copper-clad steel materials also uses exothermic welding. Exothermic welding has also been included in the corporate standards of the power grid and has become the designated grounding welding material for projects.

The exothermic welding product series consists of the following parts:

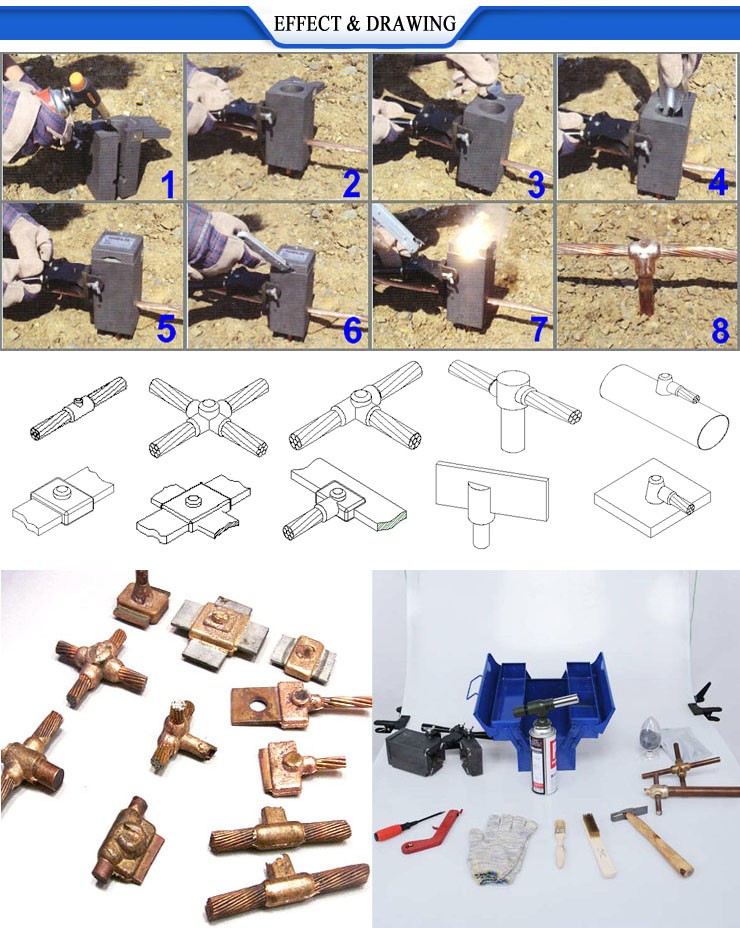

1.Exothermic Welding: It is a composition of metal (aluminum), metal oxide (copper oxide) and auxiliary materials. It is the main material used in the welding process! Usually there are aluminum foil bags for sealed packaging or filling, usually one package is required for each solder joint.

2. Exothermic welding mold: It is made of high-temperature resistant graphite material and is machined according to different needs. Usually a mold can be used 50-70 times for welding.

3. Mold clamp and tool box: The mold clamp is used to clamp the mold, and the tools in the tool box are used to clamp the mold and clean the mold!