Product Description

The grounding module is a grounding body made of conductive non-metallic materials. It is composed of non-metallic materials with good electrical conductivity and chemical stability, a metal grounding body, an electrolyte and a hygroscopic agent. It has high resistance reduction efficiency, long service life, and stability. Good sex, no pollution. Suitable for various soil environments, especially high-resistance soil environments.

Main application scope: safety grounding and lightning protection grounding in petroleum, petrochemical, electric power, electrified railway, mobile communications, and other fields.

Features

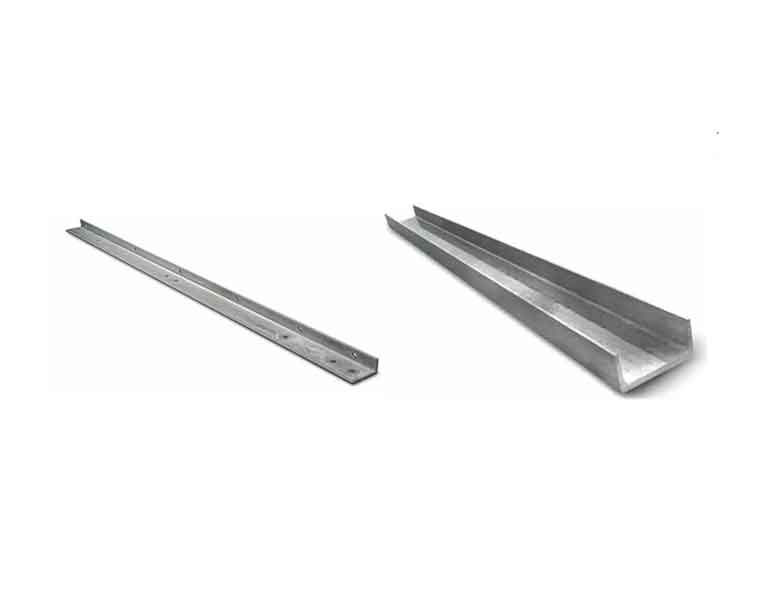

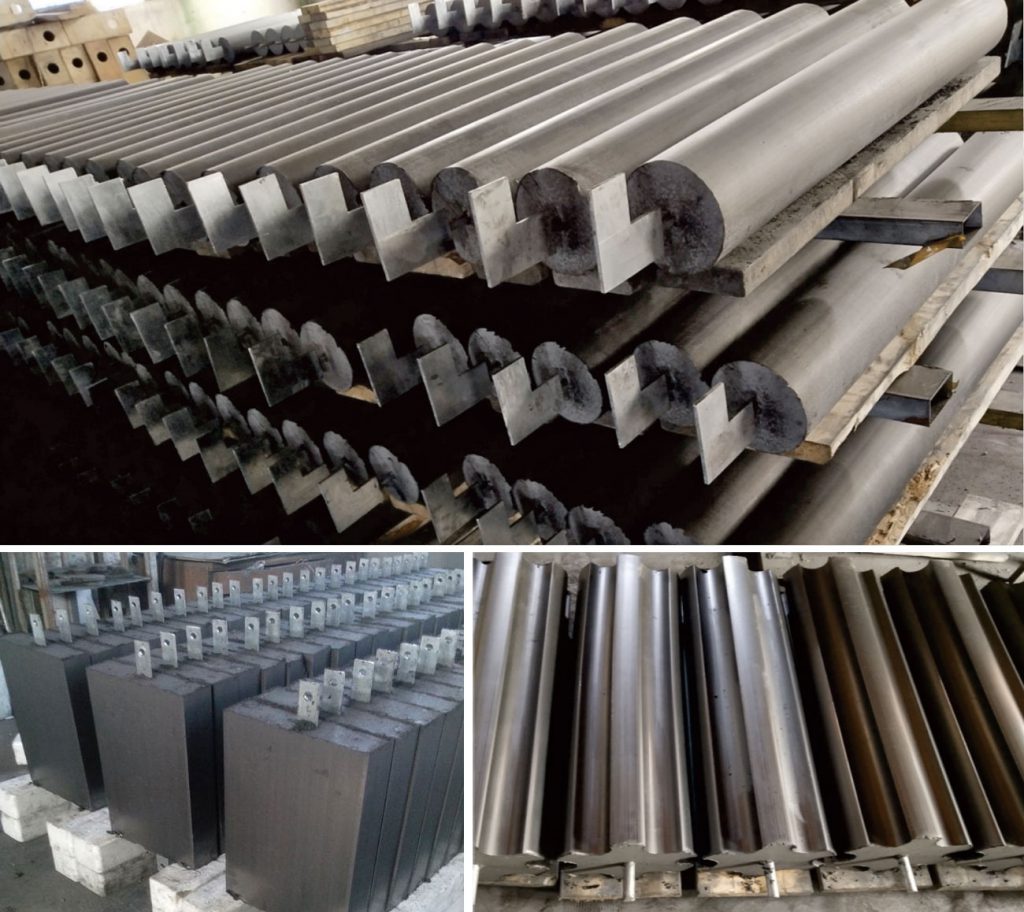

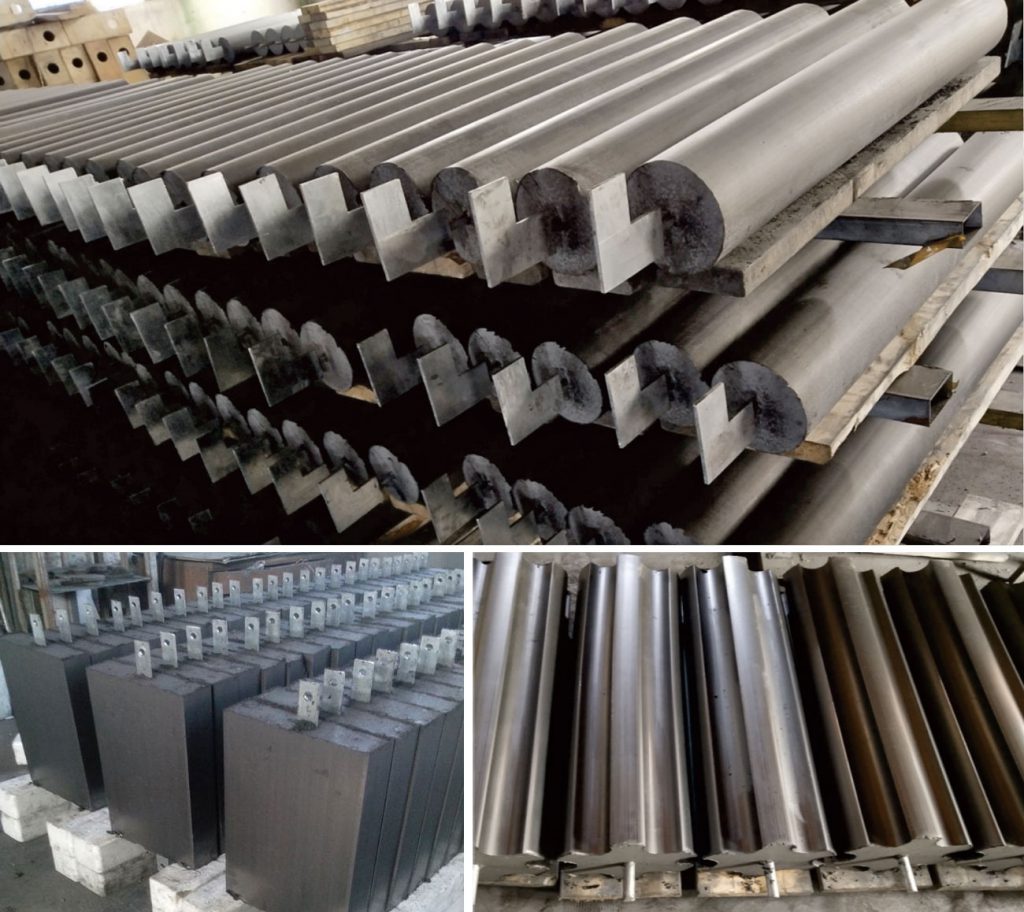

The grounding module is a grounding device with carbon material and metal material as the pole core. The shape includes a rectangular (flat plate) shape, flat trapezoidal shape, cylindrical shape, three-quincunx shape, six-quincunx shape, and other models. Special specifications and shapes can be customized. The main features of the grounding module are as follows:

1. Grounding resistance is not affected by seasons, the resistance remains stable for a long time, and the grounding resistance is low. It is more stable than steel pipes and angle steel grounding bodies.

2. In areas with high soil resistivity, it can effectively reduce ground resistance. The resistance value is stable after a large current impact, and there is no hardening, brittleness, or breakage.

3. Corrosion-resistant, environmentally friendly, pollution-free, long service life, and easy to assemble.

Specifications and models

Technical Parameters

Construction method

1. The grounding module can be buried vertically or horizontally according to the site conditions. The depth of the grounding module is 80cm below the ground.

2. When burying grounding modules, it is recommended that the distance between them should not be less than 4m (the radius of the ion scattering is 1 m-3 m, depending on the on-site geological conditions).

3. The grounding module can be connected in parallel or in parallel. Electric welding and hot melt welding can be used. The overlap length of electric welding should be greater than 3-5 times its width or more than 6 times its diameter. The welding joint should be full, even, and smooth, except for Slag and anti-corrosion.

4. When backfilling the grounding module, avoid filling with stones. Try to backfill with sticky soil. Add an appropriate amount of water and compact it in layers to ensure that it is in close contact with the earth. Do not use excessive force when compacting. Measure the grounding resistance after sufficient moisture is absorbed.

The grounding module is a grounding body made of conductive non-metallic materials. It is composed of non-metallic materials with good electrical conductivity and chemical stability, a metal grounding body, an electrolyte and a hygroscopic agent. It has high resistance reduction efficiency, long service life, and stability. Good sex, no pollution. Suitable for various soil environments, especially high-resistance soil environments.

Main application scope: safety grounding and lightning protection grounding in petroleum, petrochemical, electric power, electrified railway, mobile communications, and other fields.

Features

The grounding module is a grounding device with carbon material and metal material as the pole core. The shape includes a rectangular (flat plate) shape, flat trapezoidal shape, cylindrical shape, three-quincunx shape, six-quincunx shape, and other models. Special specifications and shapes can be customized. The main features of the grounding module are as follows:

1. Grounding resistance is not affected by seasons, the resistance remains stable for a long time, and the grounding resistance is low. It is more stable than steel pipes and angle steel grounding bodies.

2. In areas with high soil resistivity, it can effectively reduce ground resistance. The resistance value is stable after a large current impact, and there is no hardening, brittleness, or breakage.

3. Corrosion-resistant, environmentally friendly, pollution-free, long service life, and easy to assemble.

Specifications and models

| Product appearance | Specification size (mm) | Weight range (kg) |

| Rectangular (flat shape) | 500*400*60 | 20-25 |

| 500*300*80 | 20-25 | |

| 600*400*60 | 25-30 | |

| 550*450*60 | 25-30 | |

| 600*200*60 | 13-18 | |

| 600*1 50*60(Ion chamber) | 8 | |

| 400*200*60 | 11-15 | |

| 300*200*60 | 9-13 | |

| 450*450*3 | 14 | |

| 500*100*60 | 5 | |

| 600* 100*60 | 5.5 | |

| 500*130*60 | 6.8 | |

| 1000*100*100 | 18 | |

| 1000*150*100 | 26 | |

| 360*240*50 | 6.8 | |

| 480*170*120 | 18 | |

| flat trapezoid | (400+200)*500*60 | 20-25 |

| (400+200)*800*60 | 28-32 | |

| Cylindrical | 100*800 | 12-16 |

| 100*1000 | 15-19 | |

| 120*800 | 20-25 | |

| 120*1000 | 28-32 | |

| 150*800 | 28-32 | |

| 150*850 | 32-36 | |

| 150*1000 | 32-38 | |

| 200*800 | 47 | |

| 200*1000 | 57 | |

| 220*1000 | 68 | |

| 140*180 | 22 | |

| 140*1000 | 29 | |

| 260*1000 | 75 | |

| 160*600 | 24 | |

| 400*400*(40-30) | 10 | |

| 418*418*(40-30) | 10 | |

| 450*450*(40-30) | 15 | |

| Three plum blossoms | 150*800 | 22-27 |

| 150*1000 | 30-33 | |

| 200*800 | 43 | |

| 200*1000 | 55 | |

| 260*800 | 55 | |

| six quincunx shape | 260*1000 | 65 |

| 200*800 | 40 | |

| 200*1000 | 52 | |

| 260*800 | 54 | |

| 260*1000 | 65 |

| solid state resistivity | <0.20.m. |

| Inrush current withstand | Contact resistance ≤30mQ. |

| Power frequency current withstand | Contact resistance ≤30mQ. |

| Resistance reduction effect coefficient | K≤0.9%. |

| annual corrosion rate | Y≌0.03%. |

| Surface Quality | The surface of the grounding module should be continuous and smooth, without obvious unevenness or scratches. |

1. The grounding module can be buried vertically or horizontally according to the site conditions. The depth of the grounding module is 80cm below the ground.

2. When burying grounding modules, it is recommended that the distance between them should not be less than 4m (the radius of the ion scattering is 1 m-3 m, depending on the on-site geological conditions).

3. The grounding module can be connected in parallel or in parallel. Electric welding and hot melt welding can be used. The overlap length of electric welding should be greater than 3-5 times its width or more than 6 times its diameter. The welding joint should be full, even, and smooth, except for Slag and anti-corrosion.

4. When backfilling the grounding module, avoid filling with stones. Try to backfill with sticky soil. Add an appropriate amount of water and compact it in layers to ensure that it is in close contact with the earth. Do not use excessive force when compacting. Measure the grounding resistance after sufficient moisture is absorbed.